Light wear-resistant baking-free brick supporting plate and manufacturing method thereof

A technology of unburned bricks and pallets, which is applied in the direction of manufacturing tools, wood processing equipment, molds, etc., can solve the problems of easy scrapping, inconvenient use, wear and tear, etc., to save wood and steel, reduce production costs, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

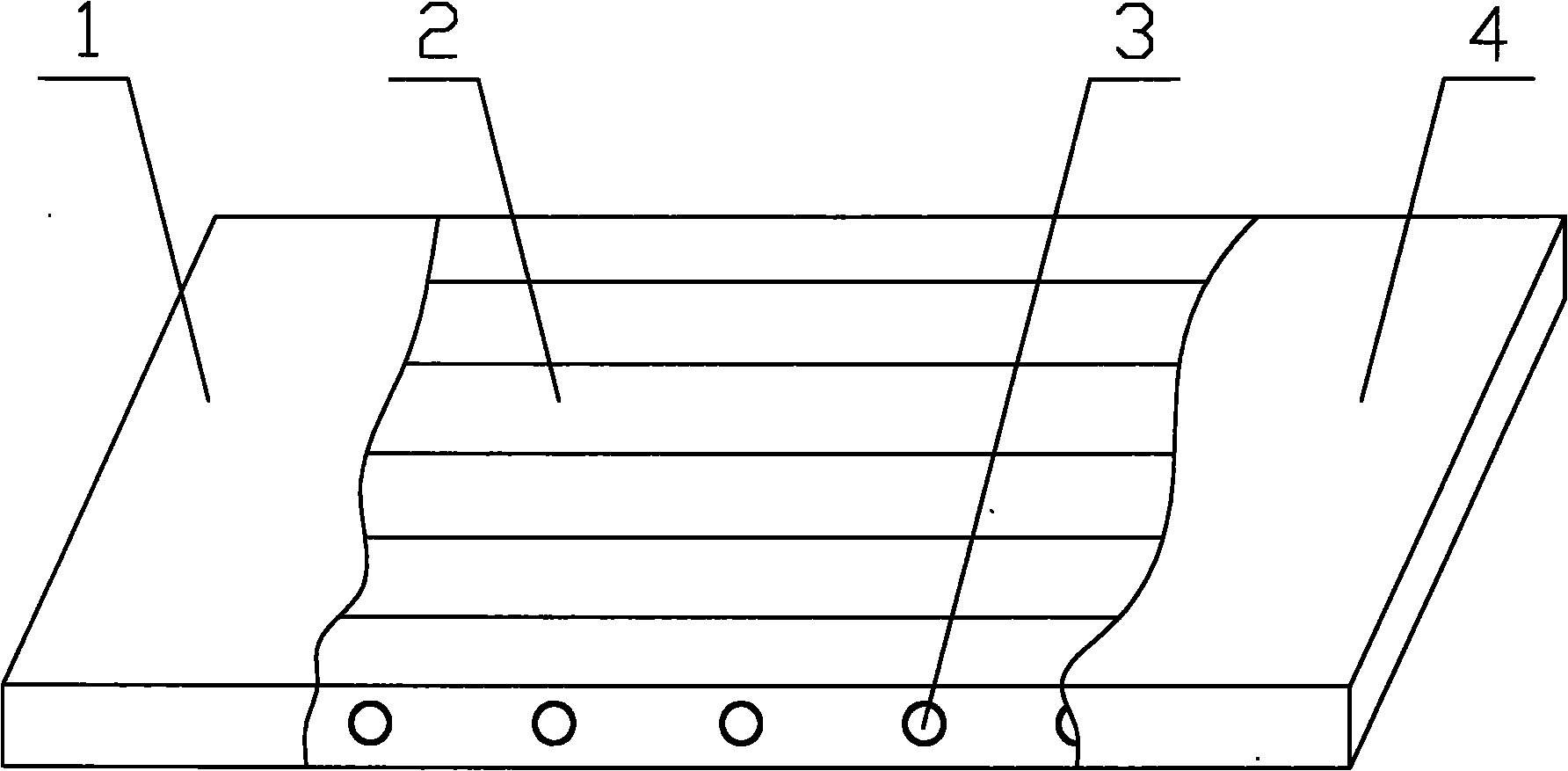

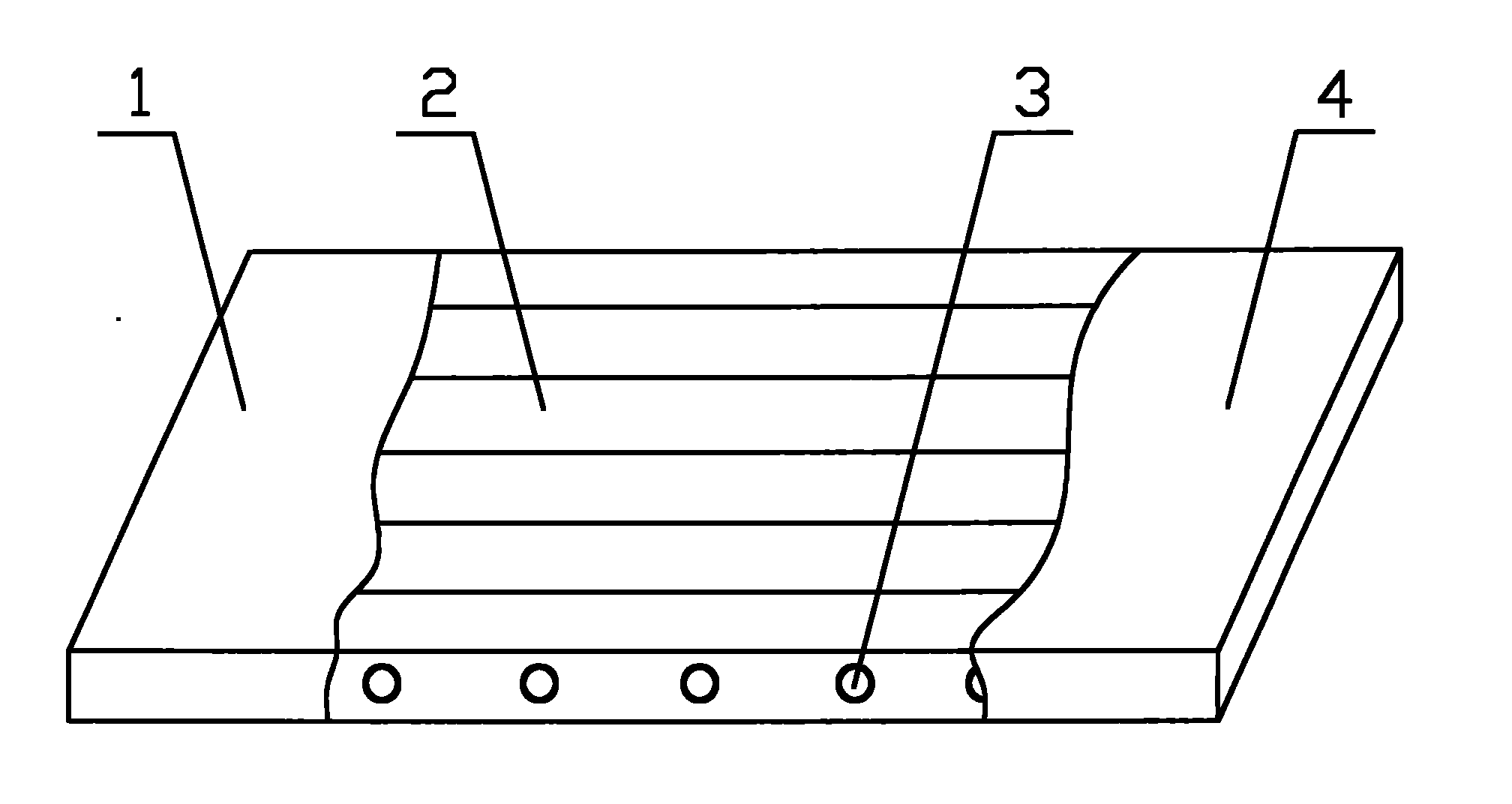

[0021] Such as figure 1 As shown, a lightweight wear-resistant unburned brick pallet 1 includes a pallet body and polymer composite wear-resistant plates 4 arranged on both surfaces of the pallet body; wherein, four of the pallet body The side is sealed with a polymer composite wear-resistant plate 4; the pallet body includes M long planks 2 and N groups of screws and nuts 3 that cooperate with each other, and N The screw rods are perforated, and the N screw rods are respectively arranged in the N bolt perforations of each long plank 2, and the nuts 3 lock the corresponding screw rods, wherein M and N are all natural numbers greater than 1; M, The specific value of N can be determined according to the size of the pallet and the load-bearing requirements of the board. Usually, the value of M is 4 or 5 or 6, and the value of N is 8-12.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com