Composite grain finer for Mg-Al alloy and preparation method thereof

A compound refiner and grain technology, applied in the field of grain compound refiner and its preparation, can solve the problems of difficult to accurately control the composition of the refiner, limited refinement effect, easy oxidation, etc., and achieve a significant refinement effect , the composition is easy to control, and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

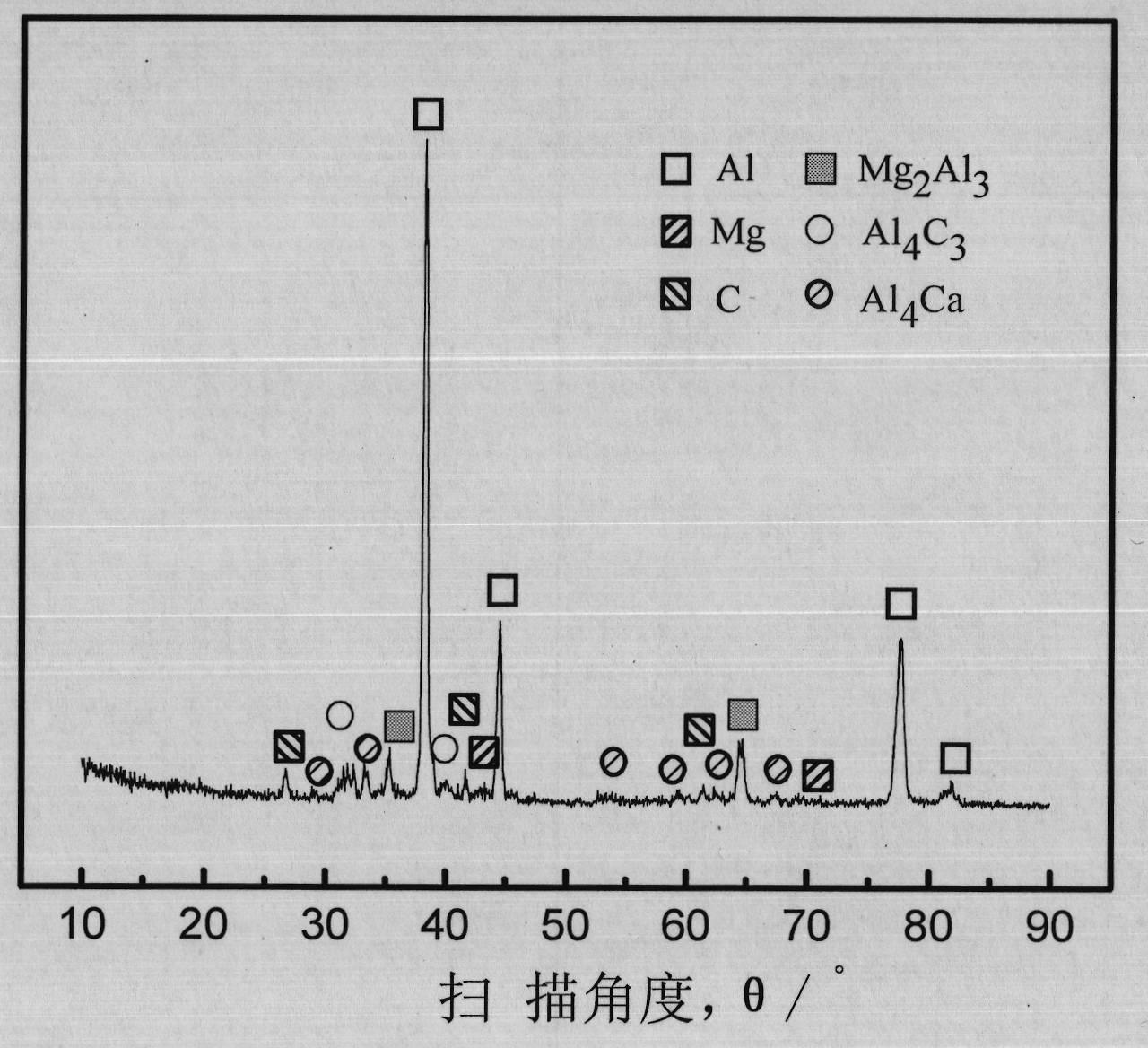

[0058] Example 1 Preparation of Al-Mg-Ca-C Grain Composite Refiner

[0059] In this example, pure Al, pure Mg, Mg-30% Ca master alloy and graphite powder were used as raw materials to prepare an Al-Mg-Ca-C grain refiner. The preparation method of the Mg-30% Ca master alloy is as follows: put pure magnesium and pure Ca into a low-carbon steel crucible with a mass ratio of 7:3, then put it into a vacuum furnace, vacuumize and heat to 750°C, and melt Finally, the crucible is taken out, stirred properly, and cast into a mold to obtain the Mg-30%Ca master alloy.

[0060] The preparation method of Al-Mg-Ca-C grain compound refiner is as follows: melt 55g of pure Al at 750°C, add 27g of Mg according to the formula (Ca8.1%, Al 55%, 3% C, and the rest is Mg) -30% Ca master alloy and 15g pure Mg to obtain an Al-Mg-Ca master alloy melt; the Al-Mg-Ca master alloy melt is cooled to 630°C and stirred at a stirring speed of 400r / min, While stirring, use a long-mouthed funnel to slowly add ...

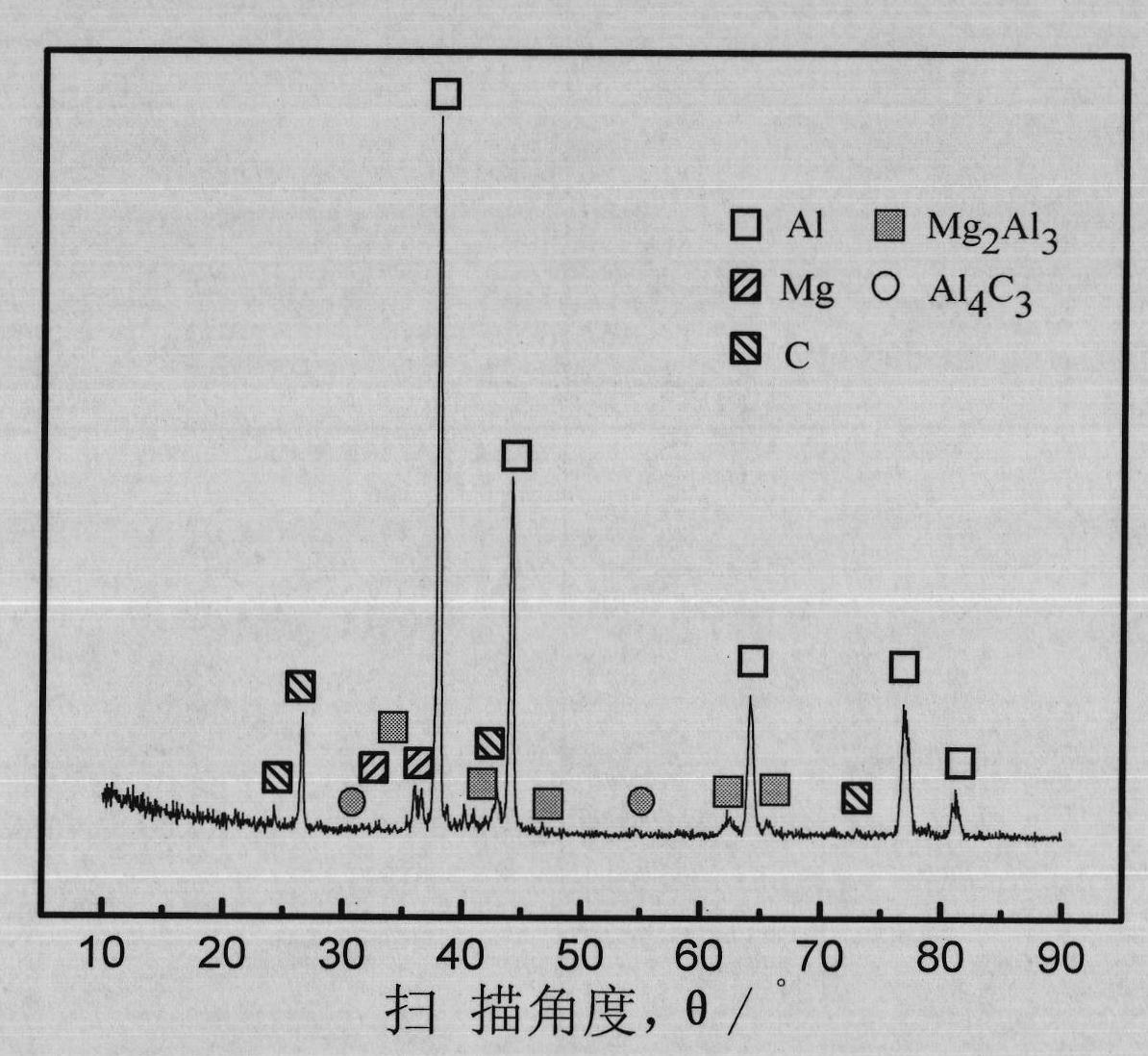

Embodiment 2

[0061] Example 2 Preparation of Al-Mg-Ca-C Grain Composite Refiner

[0062] In this example, pure Al, pure Mg, Mg-30% Ca master alloy and graphite powder were used as raw materials to prepare an Al-Mg-Ca-C grain refiner. Its preparation method is: melt 50g of pure Al at 700°C, stir evenly, add 17g of Mg-30% Ca and 32g of pure Mg according to the formula (Ca 5%, Al 50%, C 1%, the rest is Mg), and obtain Al-Mg-Ca master alloy melt; cool the Al-Mg-Ca master alloy melt to 600°C, and stir it at a stirring speed of 200r / min, while stirring, use a long-mouthed funnel to the center of the stirring vortex Slowly add graphite powder with a particle size of 8-15 μm in an amount of 1 g, and stir for 3 minutes to obtain a semi-solid melt. Cast the semi-solid melt to obtain the grain compound refiner Al-Mg-Ca-C of the present invention.

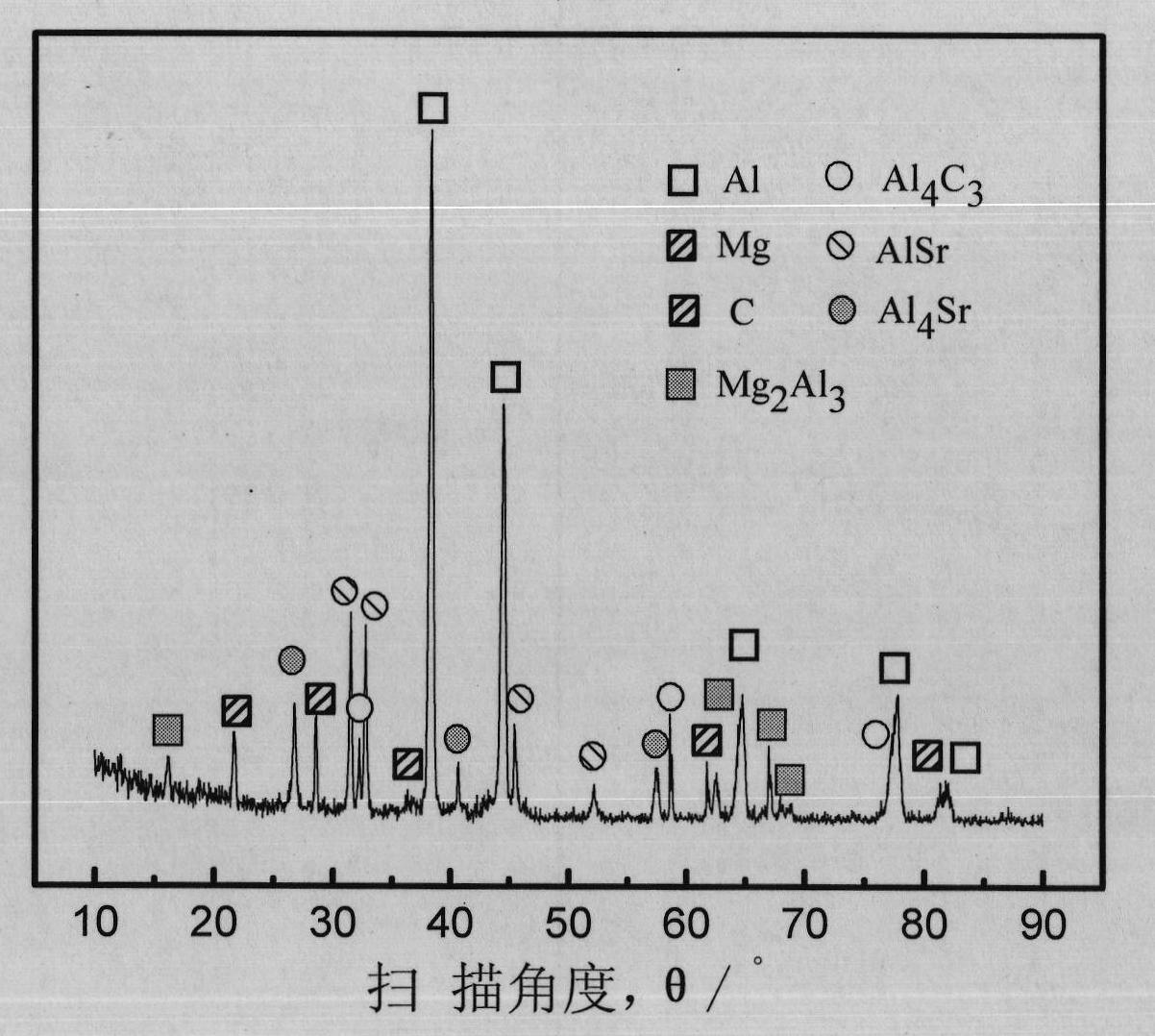

Embodiment 3

[0063] Example 3 Preparation of Al-Mg-Ca-C Grain Composite Refiner

[0064] In this example, pure Al, Mg-30% Ca master alloy and graphite powder were used as raw materials to prepare an Al-Mg-Ca-C grain refiner. Its preparation method is: melt 60g of pure Al at 800°C, stir evenly, add 35g of Mg-30%Ca according to the formula (10.5% Ca, 60% of Al, 5% of C, and the rest is Mg) to obtain Al-Mg-Ca Master alloy melt: Cool the Al-Mg-Ca master alloy melt to 650°C and stir it at a stirring speed of 500r / min. While stirring, slowly add a particle size of 8 to the center of the stirring vortex using a long-mouthed funnel. ~ 15 μm graphite powder, added in an amount of 5 g, and then stirred for 3 minutes to obtain a semi-solid melt. Cast the semi-solid melt to obtain the grain compound refiner Al-Mg-Ca-C of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com