Packing and steam cooking device and method for manufacturing steam cooking device

A cooker and liner technology, which is applied in the field of steam cookers, can solve problems such as vitamin C oxidation, air tightness reduction, and oxygen concentration increase, so as to reduce friction sound and friction heat, improve air tightness, and reduce rubbing off The effect of the grease process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

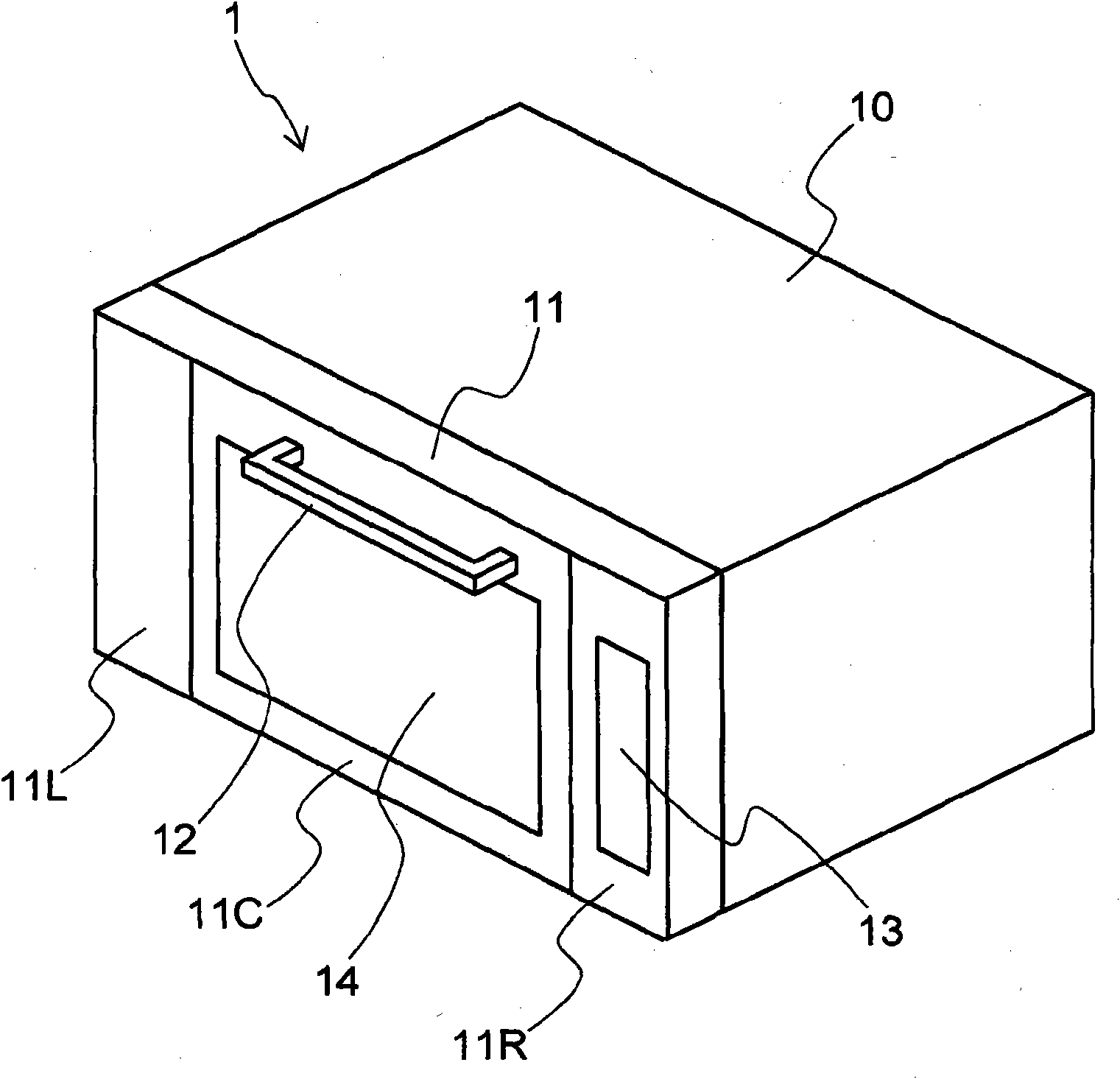

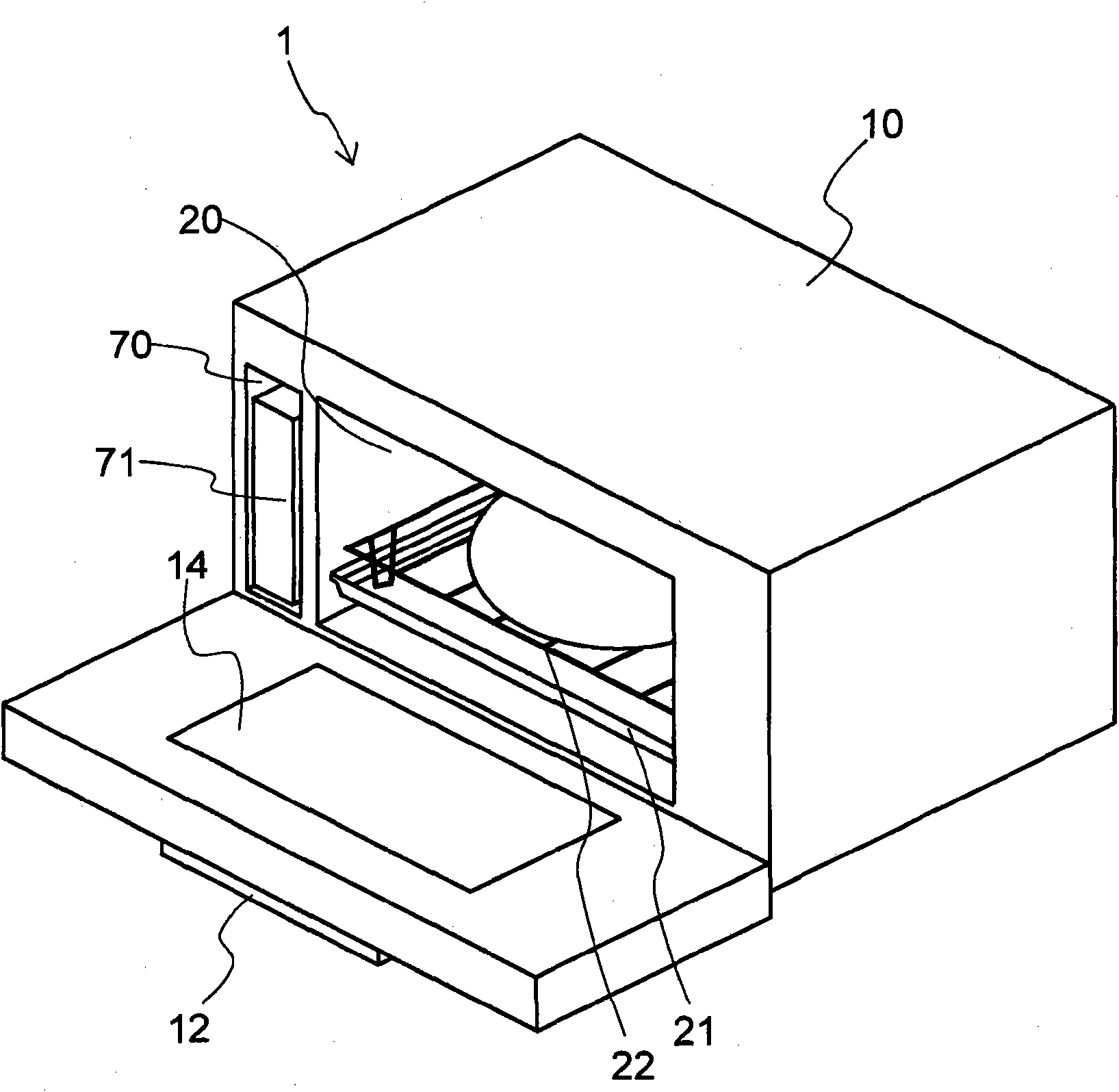

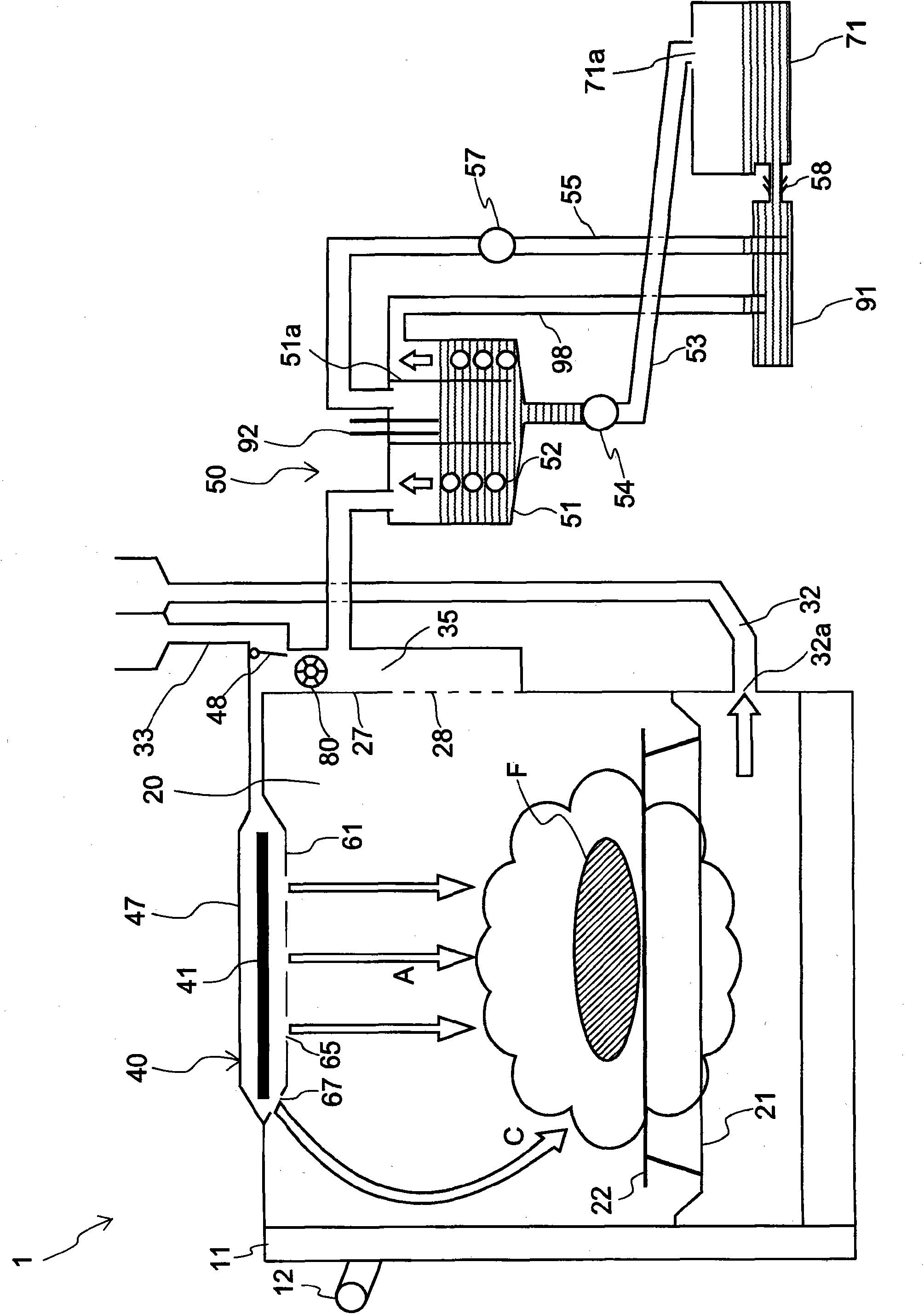

[0084] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a perspective view which shows the steam cooker which concerns on embodiment of this invention. figure 1 The shown steam cooker 1 is used for cooking objects to be heated with superheated steam. Furthermore, the steam cooker 1 has a rectangular parallelepiped cabinet 10, and a door 11 is provided on the front side of the cabinet 10.

[0085] The door 11 is pivotally supported rotatably in a vertical plane centering on the lower end, and a handle 12 for opening and closing the door 11 is provided on the upper part. In the center part 11C of the door 11, the transmission part 14 which fits heat-resistant glass and allows visual inspection of the inside is provided. Left-side part 11L and right-side part 11R provided with a metal decorative plate on the surface are arrange|positioned bilaterally symmetrically to center part 11C. Furthermore, an operation panel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com