Outer cylinder assembly structure and welding joint for dual-cylinder shock absorber

A technology for welding joints and assembly structures, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of high welding process difficulty, high equipment investment cost, limited application scope, etc. The effect of reducing the consumption, improving the utilization efficiency of electric energy, and improving the safety level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

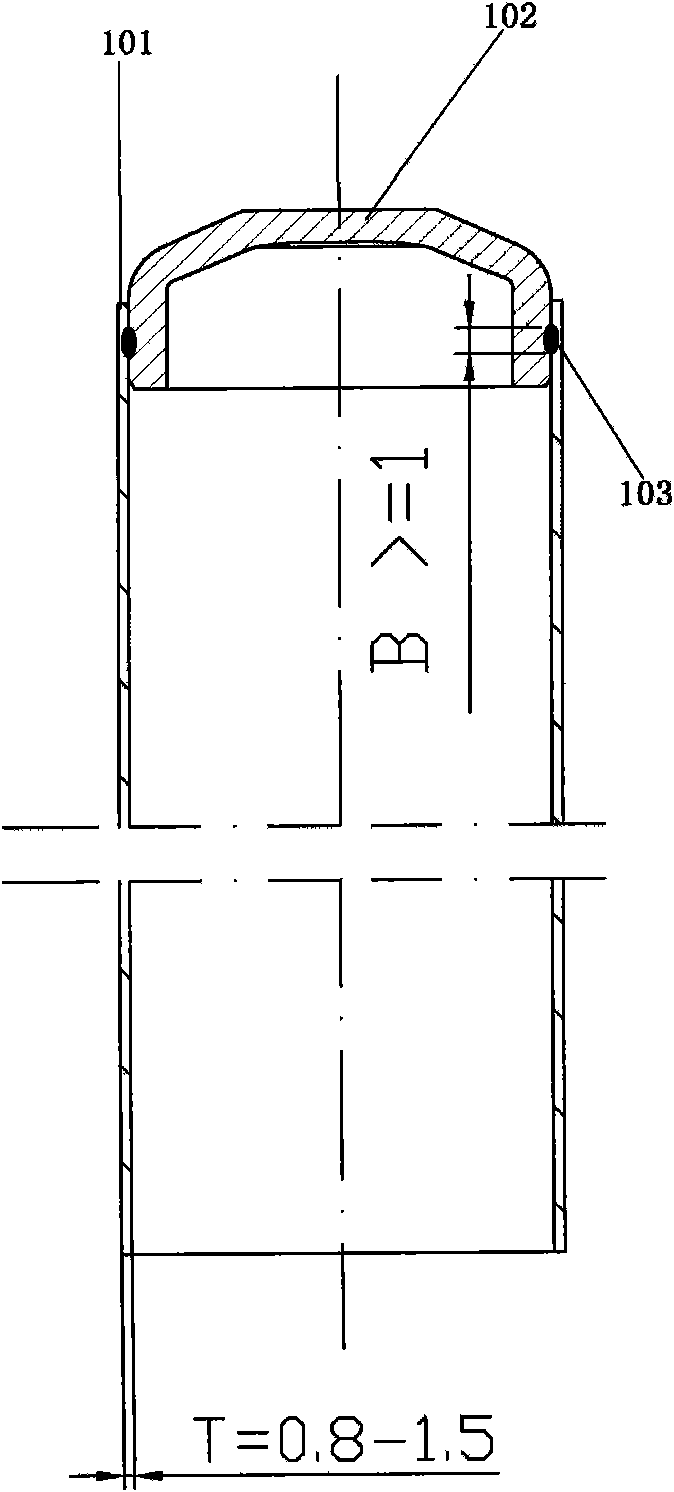

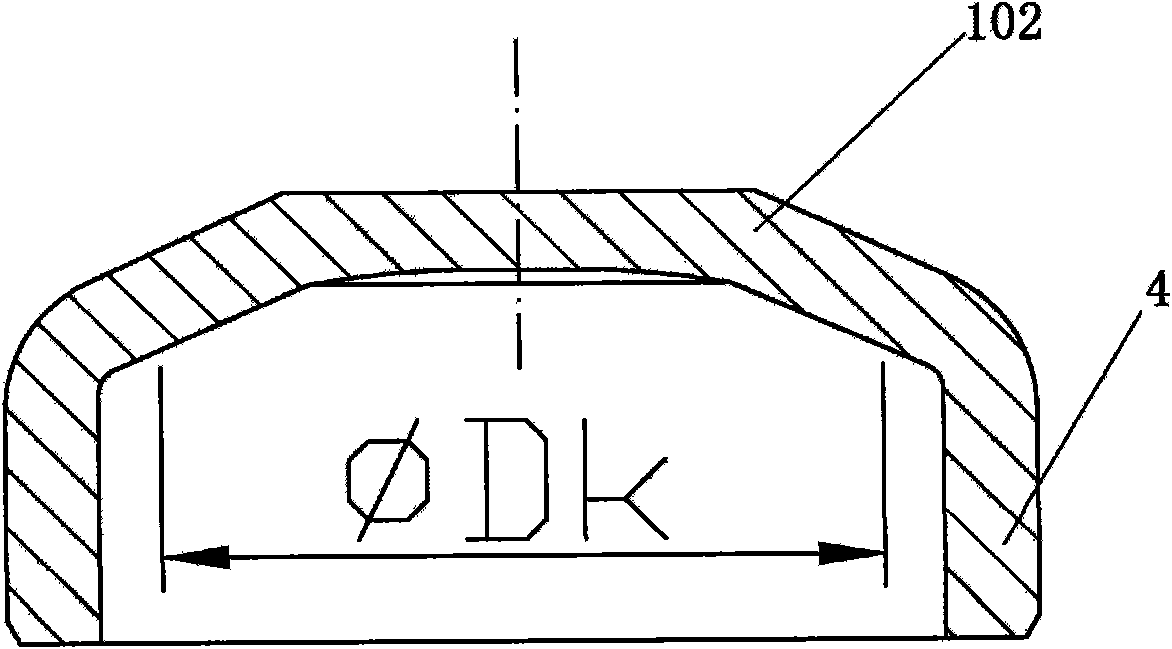

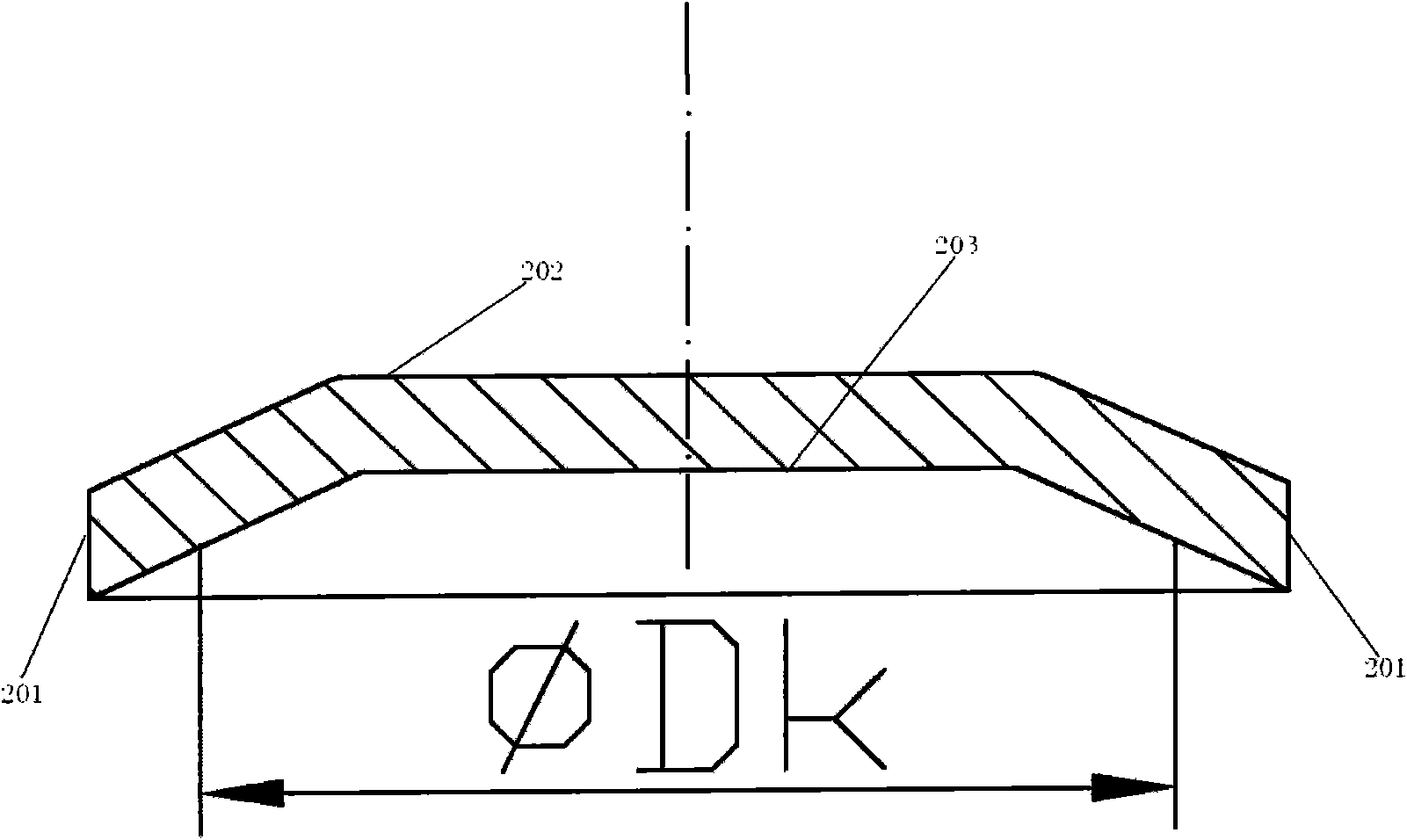

[0041] see Figure 4 , in this figure, the wall thickness T of the outer cylinder part 1 is between 0.8 mm and 1.5 mm, and the outer cylinder is cut and prepared by the prior art (the shrinkage cavity, reaming hole, and partial compression cavity that may be present in the actual product are omitted in this figure. shape change caused by flat); its bottom cover 2 parts such as image 3 As shown,. Its concave and convex surfaces have various boundary conditions required to match the outer cylinder, bottom valve, lifting lug / suspension and other components: for example, in order to match the bottom valve of the shock absorber, the concave surface of the bottom cover 2 part has a Control dimension ¢Dk, and a conical surface near this dimension; for example, in order to match the installation in the car suspension, the bottom has an outer plane.

[0042] exist image 3 The part of the middle bottom cover 2 has a section of cylindrical surface 201 in its convex surface for match...

Embodiment 2

[0048] see Figure 5 , which is a double tungsten argon arc welding process without external wire feeding. In this figure, the wall thickness T of the outer cylinder part 1 is between 0.8 millimeters and 1.5 millimeters, and the outer cylinder is cut and prepared by the prior art (this figure omits possible shrinkage cavities, reaming holes, and partial flattening in actual products. resulting in shape changes); its bottom cover 2 parts such as image 3 shown. Its concave and convex surfaces have various boundary conditions required to match the outer cylinder, bottom valve, lifting lug / suspension and other components: for example, in order to match the bottom valve of the shock absorber, the concave surface of the bottom cover 2 part has a Control dimension ¢Dk, and a conical surface near this dimension; for example, in order to match the installation in the car suspension, the bottom has an outer plane.

[0049] exist image 3 The part of the middle bottom cover 2 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com