Groove pin structure of warp knitting machine

A technology of warp knitting machine and grooved needles, which is applied in warp knitting, knitting, textiles and papermaking, etc. It can solve the problems of synchronous forward movement of the cloth surface, easy damage of the grooved needles, and large resistance of the grooved needles, achieving small resistance, Not easy to damage, high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

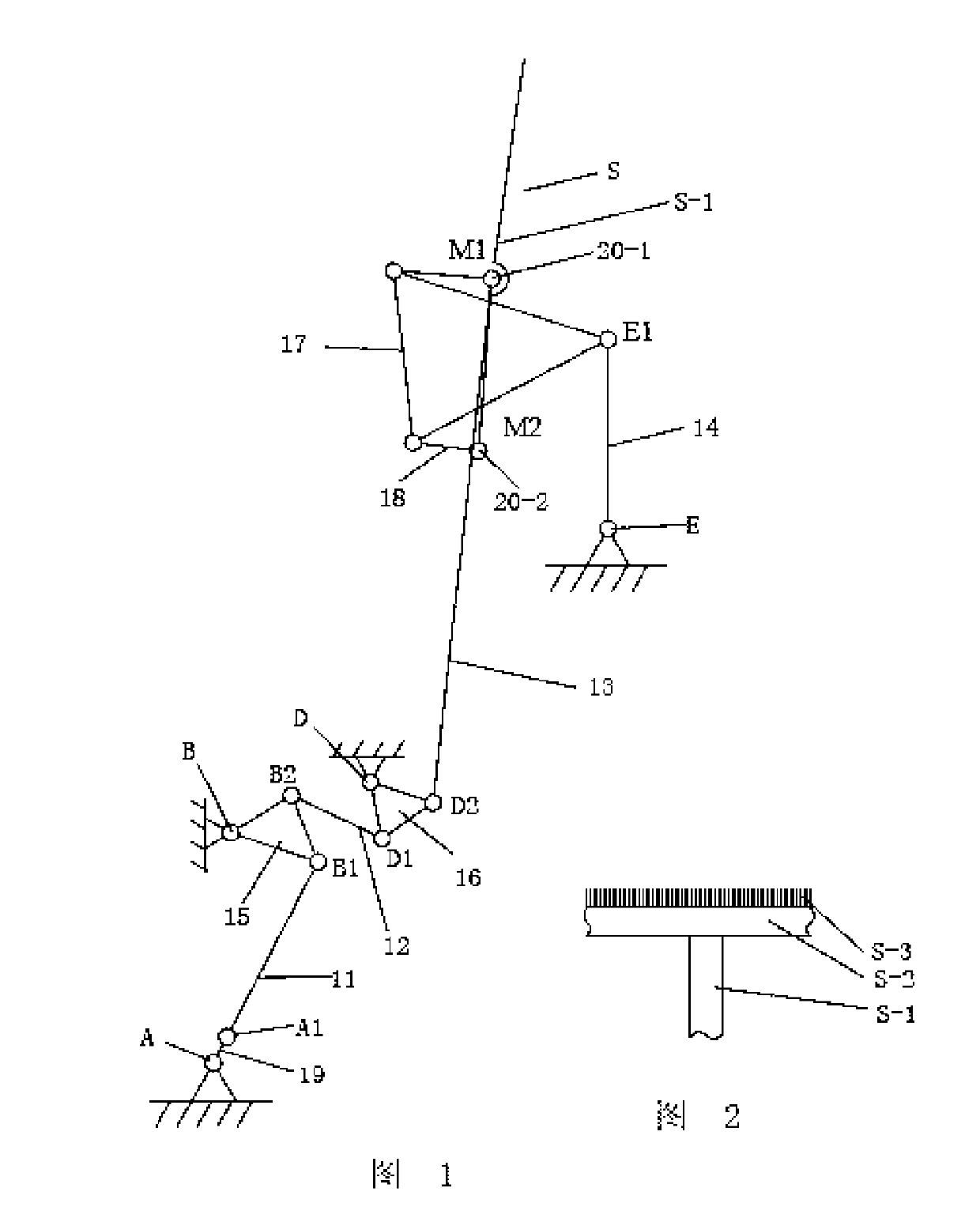

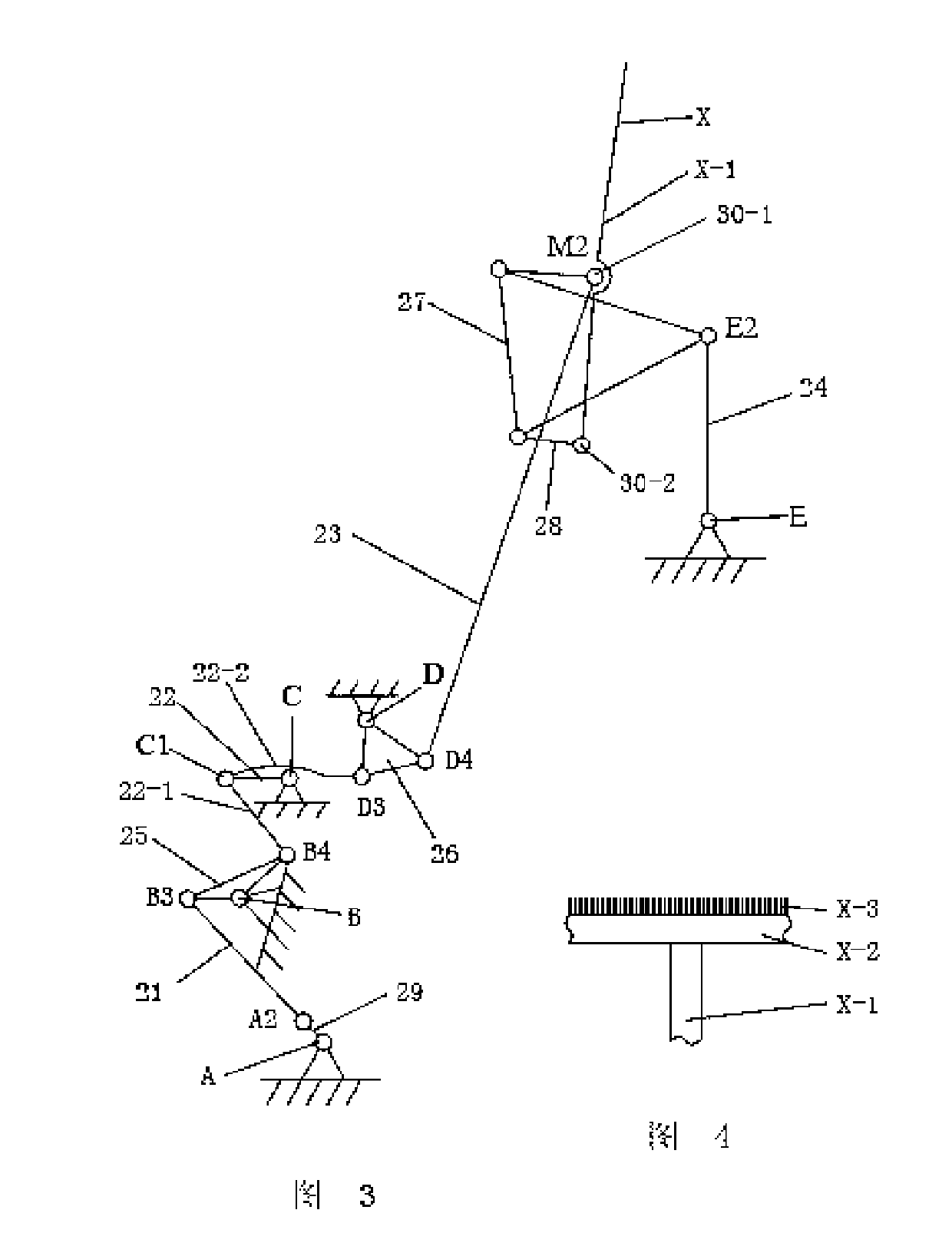

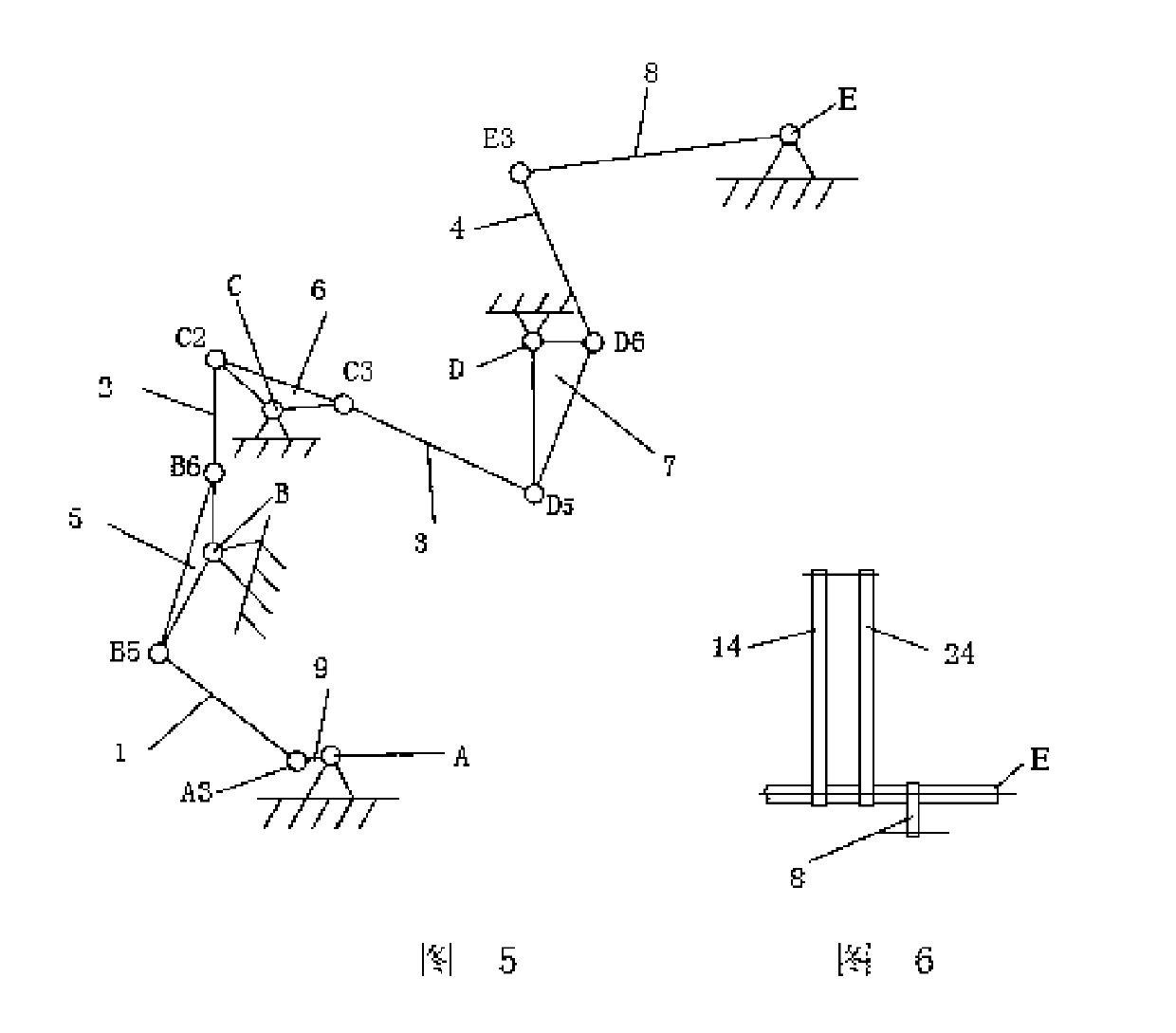

[0026] The embodiment shown in the drawings includes a main shaft A, a needle body assembly S and a needle core assembly X, and the needle body assembly S and the needle core assembly X are respectively driven by the needle up and down movement mechanism and the needle core up and down movement mechanism. In addition, it also includes a front and rear movement mechanism, No. 1 long pin shaft B, No. 2 long pin shaft C, No. 3 long pin shaft D and swing shaft E. Above-mentioned main shaft A, No. 1 long pin shaft B, No. 2 long pin shaft C, and No. 3 long pin shaft D are in the oil tank of the warp knitting machine and are respectively supported by a support. The swing axis E is supported by a bracket fixed to the top of the tank. Main shaft A, No. 1 long pin shaft B, No. 2 long pin shaft C, No. 3 long pin shaft D and swing shaft E are long shafts equal to the width of the machine. The main shaft A is the power input shaft of the main movement of the warp knitting machine, driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com