An experimental device for simulating load-temperature coupled wear of pdc teeth

An experimental device and load technology, which can be used in measurement devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of inability to control the temperature of PDC teeth, wear of PDC teeth, and restrict the development of PDC bits. Precise and reliable effect of ambient temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

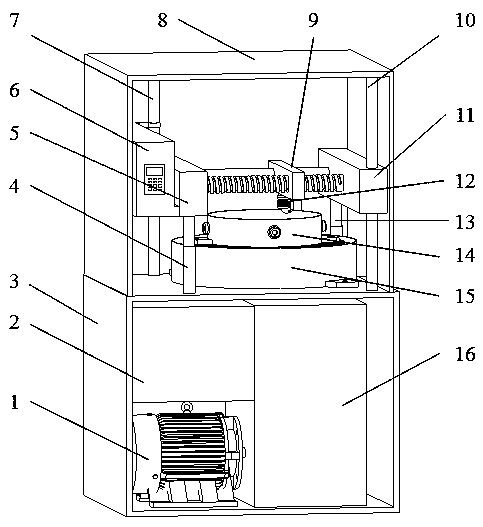

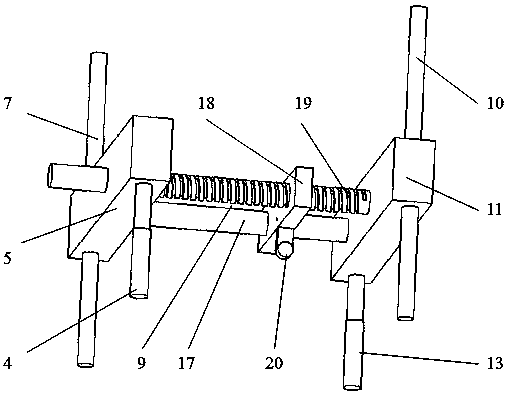

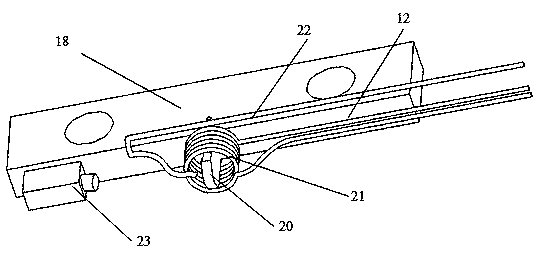

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention is an experimental device for simulating PDC tooth load temperature coupling wear, including a motor 1, a hydraulic power source 2, a lower support frame 3, a left hydraulic cylinder 4, a left guide loading block 5, a miniature power end 6, Left guide column 7, upper support frame 8, PDC tooth traverse mechanism 9, right guide column 10, right guide loading block 11, temperature measurement and control mechanism 12, right hydraulic cylinder 13, rock rotation mechanism 14, chip removal device 15, reduction box 16. The PDC tooth traversing mechanism 9 is composed of a transverse guide column 17, a PDC tooth clamp 18, a screw 19 and a PDC cutter tooth 20; the temperature control mechanism 12 is composed of a heating wire 21, a water cooling tube 22, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com