Automatic drug mixer

A drug mixing machine and automatic technology, which is applied in the direction of mixers, mixers with rotating containers, mixer accessories, etc., can solve the problems of unfavorable safety and health in the production environment, affect efficiency, and low degree of automation, so as to improve the mixing effect and mixing efficiency, reduce production risk, and improve the effect of production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

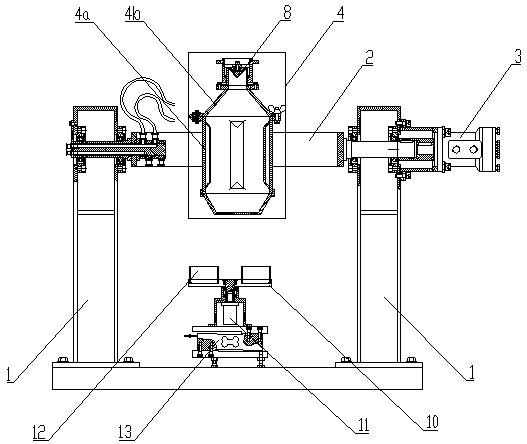

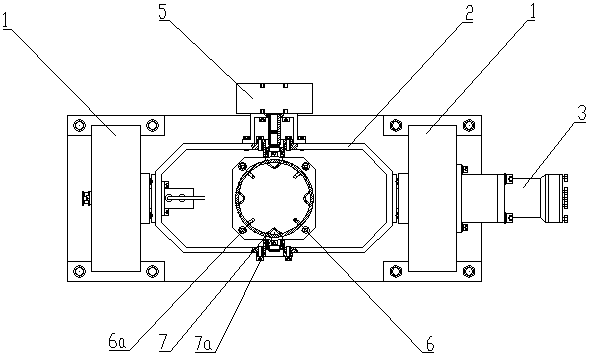

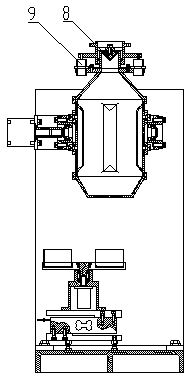

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the automatic medicine mixing machine of this embodiment includes two brackets 1 arranged side by side, and a rotating arm 2 arranged on the bracket 1 in a rotationally fitted manner. , the rotating motor 3 that is used to drive the rotation of the rotating arm 2, the mixing pot 4 arranged on the rotating arm 2 and the material receiving device arranged under the mixing pot 4, the rotating arm 2 is supported on two supports by bearings, so that It can be driven by a rotating motor 3 to rotate 360 degrees. The medicine mixing pot 4 can rotate and cooperate with the pivoting arm 2 in a manner that can swing back and forth to both ends of the pivoting arm 2 . , the rotating arm 2 is a frame structure, the medicine mixing pot rotates and cooperates with the vertical sides of the rotating shaft of the rotating arm through bearings, and the medicine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com