Method for preparing amorphous carbon coating on surface of medical stainless steel knife saw

A technology of amorphous carbon coating and stainless steel knife, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of surface hardness, poor mechanical and biological properties, etc., and achieve cell growth Good, good for oral health, high cell density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0027] A method for preparing an amorphous carbon coating on the surface of a medical stainless steel knife saw:

[0028] (1) Use acetone solution to soak the plated parts such as knives, saws, dental trays and other stainless steel materials used for beauty, surgery, ophthalmology, dentistry, etc., use ultrasonic cleaning, alcohol dehydration, and finally blow dry with nitrogen;

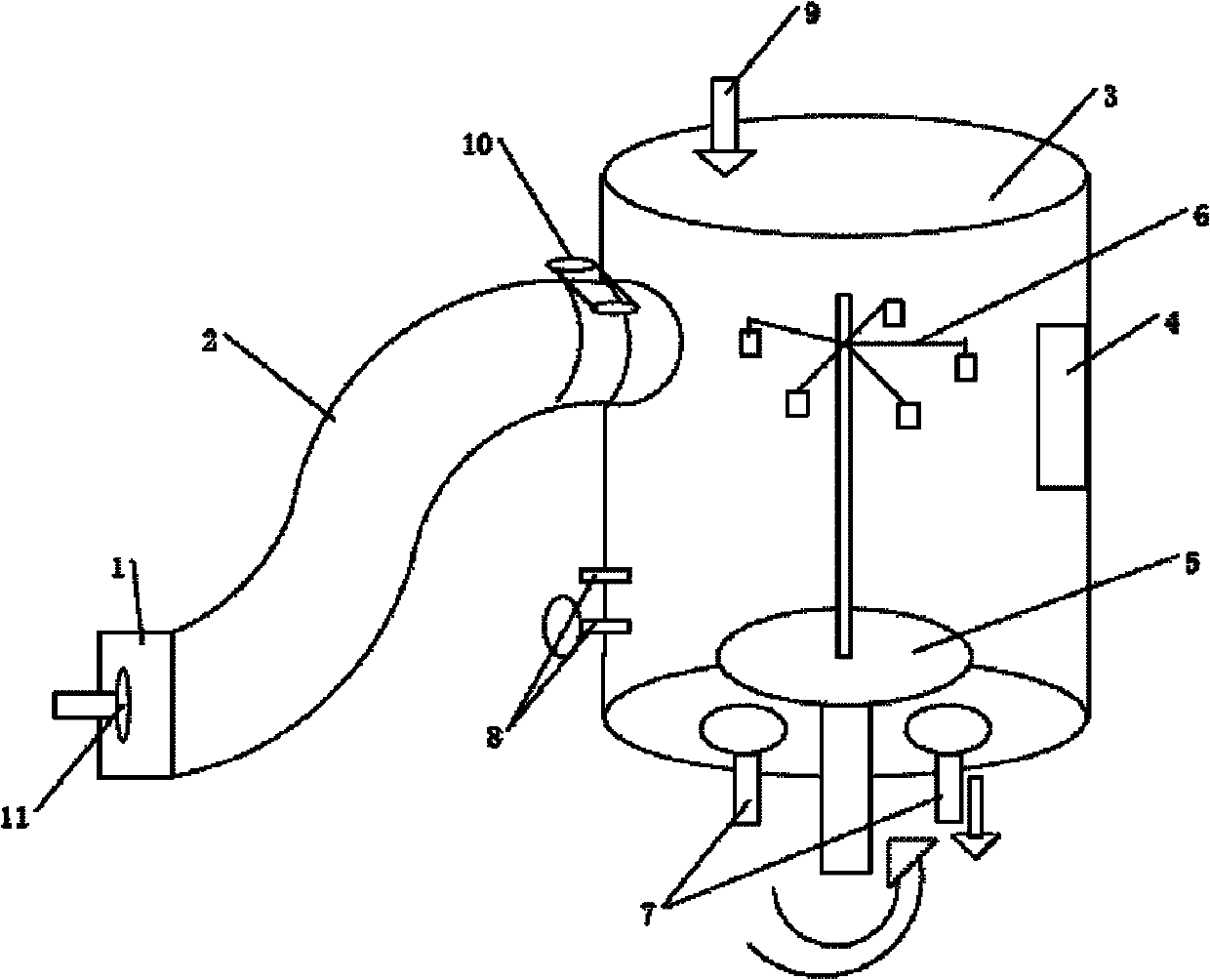

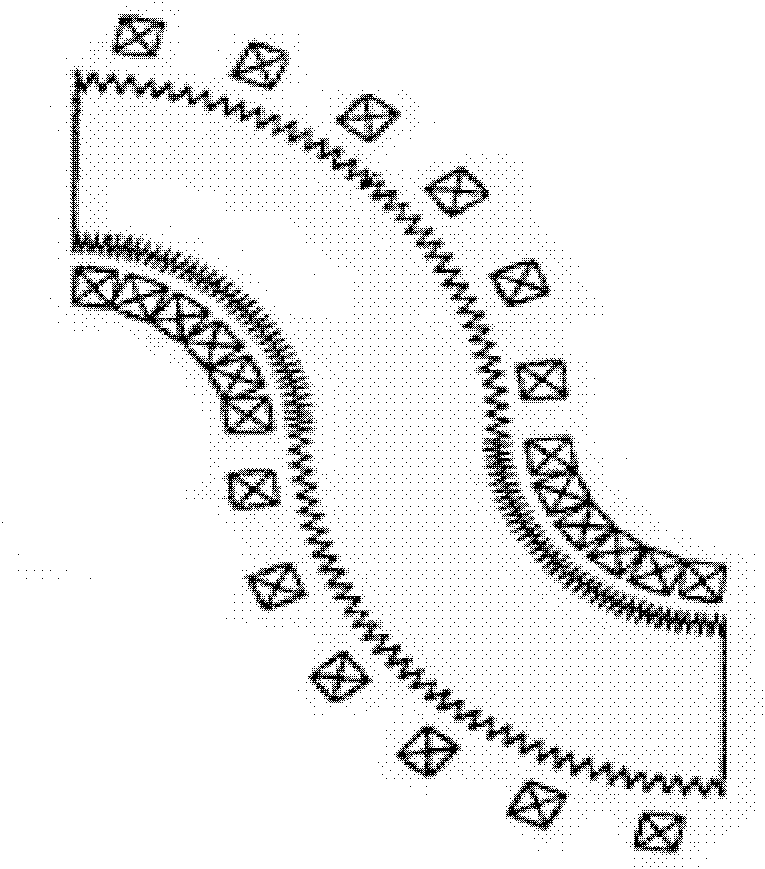

[0029] (2) pack the plated parts after cleaning into the tooling frame 6, put it into the tooling turntable 5 in the vacuum chamber 3 of the coating machine immediately, as figure 1 As shown, prevent re-contamination and affect the coating quality. The coating coating equipment at least includes a filtered arc ion source 1, an S-shaped magnetic filter device 2, a vacuum chamber 3, a cold cathode ion source 4, a tooling turntable 5, a tooling frame 6, an air suction port 7, an air inlet 8, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com