Engine coolant

A technology of engine coolant and tricarboxylic acid, which is applied in the field of chemical combination, can solve problems such as insufficient coolant technology, cavitation corrosion, and blackening of cast aluminum, and achieve long-term corrosion inhibition, corrosion prevention, and hard water resistance strong effect

Active Publication Date: 2010-07-07

北京蓝星清洗有限公司

View PDF3 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The present invention overcomes the above technical deficiencies of the existing all-organic acid engine coolant, solves the problems of cast aluminum blackening and cavitation corrosion, and provides an all-organic acid coolant that has a comprehensive protection effect on the multi-metal of the cooling system

The application of the phosphate ester proposed in the present invention, compared with the traditional organic acid type engine coolant, solves the problem of blackening of cast aluminum, and makes the engine coolant of the present invention protect the engine cooling system more comprehensively

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

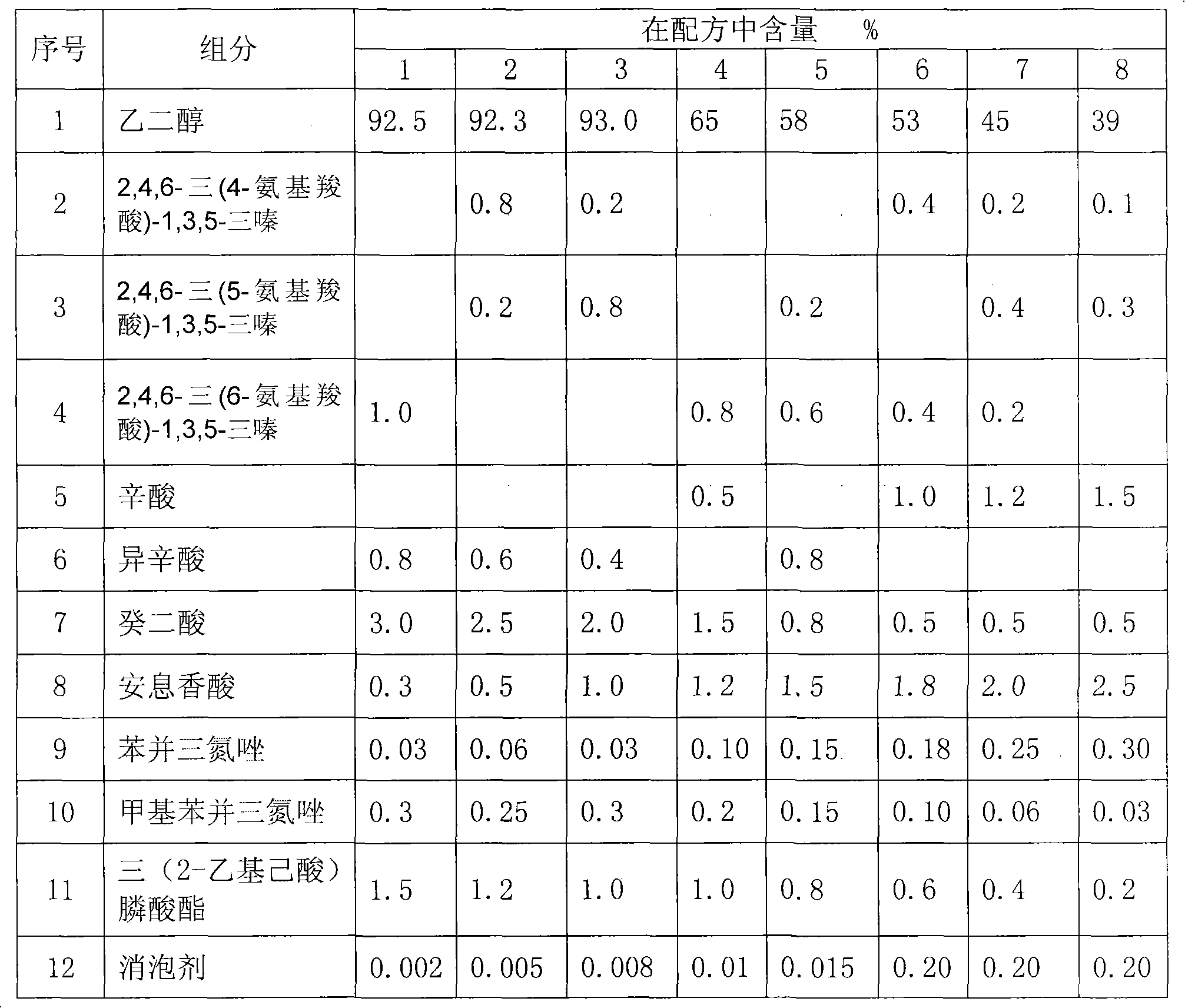

[0029] Engine coolant of the present invention, through a large amount of screening experiments, has obtained the formula combination of economic rationality and excellent performance, and table 1 is 8 embodiment formulas:

[0030] Table 1

[0031]

[0032]

[0033] Engine coolant performance index data of the present invention is shown in Table 2

[0034] Table 2 Performance Index

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

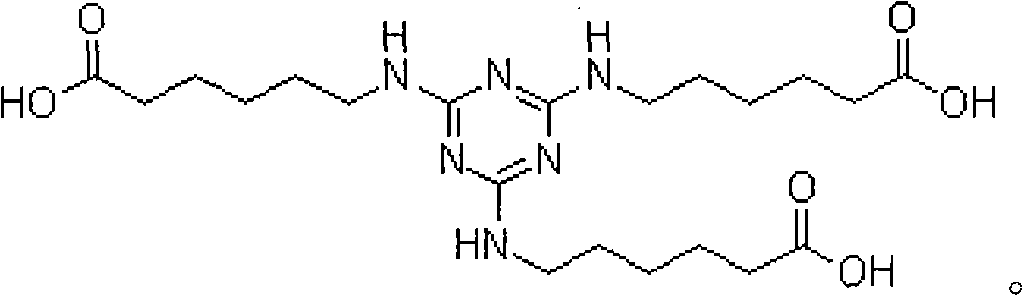

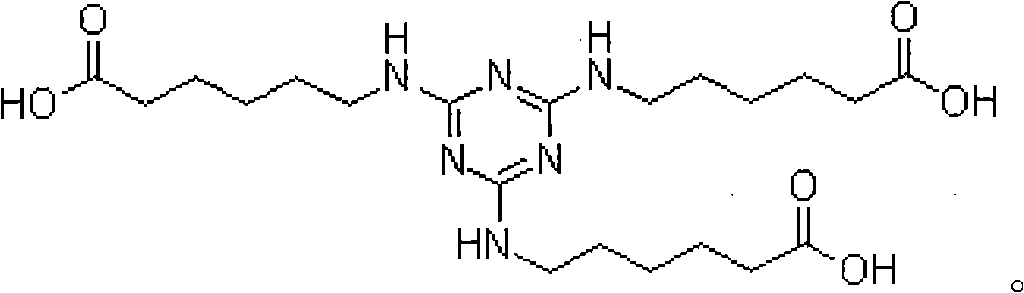

Login to View More Abstract

The invention provides an all-organic type engine coolant which comprises glycol, fat carboxylic acid, tricarboxylic acid, benzoic acid, tri (2-ethylhexoic acid) phosphonate, imidazoles compound, defoamer and deionized water. The engine coolant of the invention contains no inorganic salts, such as amines, borate, nitrate, nitrite, silicate, and the like, so the engine coolant is environment-friendly, can prevent all the contacted metal and nonmetal materials in the engine cooling system from being corroded, has an obvious engine coolant effect on various metals, particularly solves the problem that the cast aluminum using a traditional organic acid engine coolant becomes black generally, can be stabled in a relative low density and bigger PH value range, and has the advantages of long-time storage and use.

Description

technical field [0001] The invention relates to an engine coolant, which belongs to the technical field of chemical combination technical background [0002] The development of engine coolant is greatly affected by the composition and materials of automobile engines. With the rapid development of automobile engine technology, the requirements for engine coolant are becoming increasingly stringent, so the upgrading of engine coolant is also accelerating. The development trend of the automobile industry in recent years is that the power of the engine is increasing. In order to reduce the drag coefficient, the streamlined shape is generally adopted, so that the volume of the engine radiator becomes smaller and smaller, and the thermal load of the engine continues to increase. In order to reduce the weight of the car body and increase fuel economy, not only the engine cooling system uses a large amount of aluminum alloy, but also other parts of the engine are gradually aluminum ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K5/20C23F11/167

Inventor 王双田白剑利沈一飞邱雪梅李德福张桂玲卢小兵

Owner 北京蓝星清洗有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com