Hygroscopic, perspiratory and antibacterial sock and production process thereof

A technology of moisture absorption and perspiration, production process, applied in socks, pantyhose, clothing and other directions, can solve the problems of difficult processing, high production cost, inability to meet moisture absorption and perspiration and antibacterial, etc., to achieve low production cost and easy processing Manufactured, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Implementation Example 1: Moisture Absorption and Perspiration Antibacterial Sports Socks

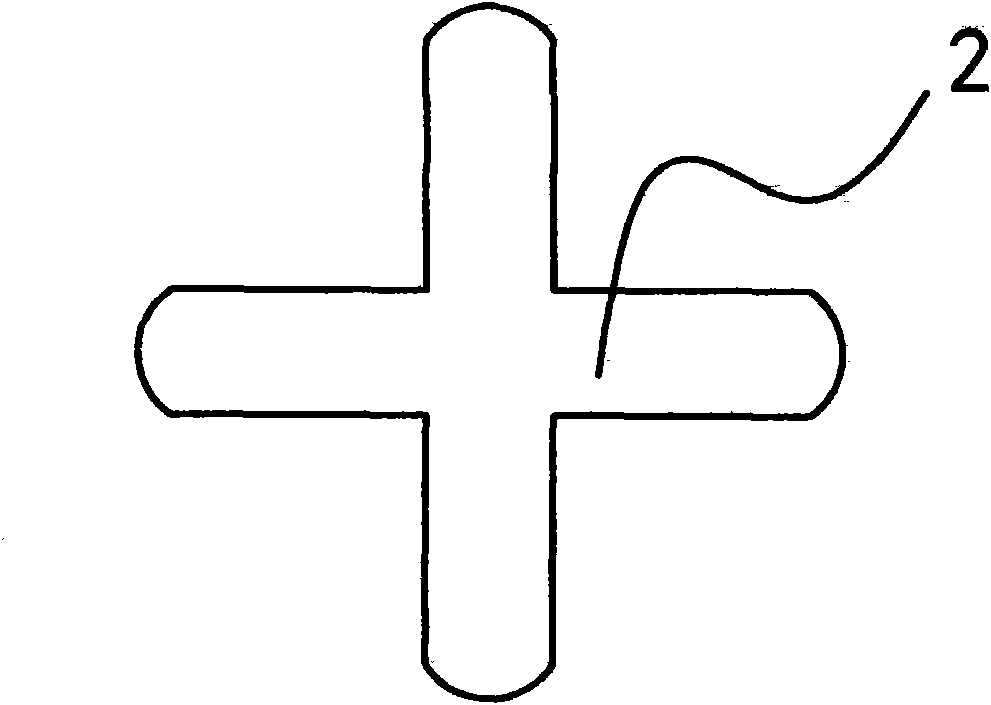

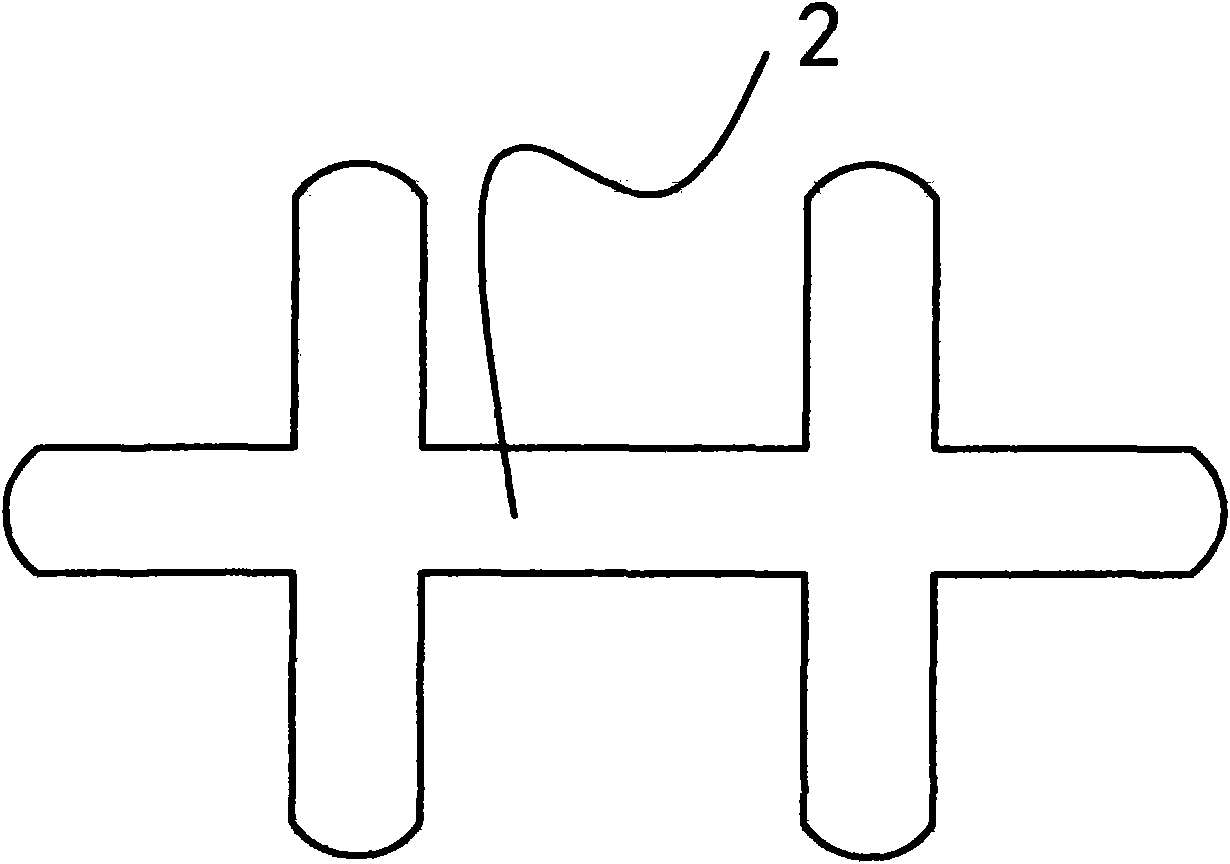

[0041] Weaving process: product name SEECOME silver ion antibacterial sports socks, raw materials: 30 / 70 cross shaped silver antibacterial nylon covered yarn, 70D / 48F cross shaped silver antibacterial nylon, bamboo fiber 32 S .

[0042] Raw material ratio: 28% cross shaped silver antibacterial nylon, 67% bamboo fiber, 5% spandex.

[0043] Weaving machine: lonati Italian hosiery machine

[0044] Spandex-wrapped yarn first, using 30D spandex and 70D / 48F cross-shaped silver antibacterial nylon, with a stretch ratio of 3.5 times.

[0045] The lonati Italian hosiery machine is used to weave and shape.

[0046] After the head is hand-stitched, bleached, and two steam-pressed to finish.

[0047] The socks were tested by FZT73023-2006 antibacterial standard, washed 50 times, the bacteriostatic rate of Staphylococcus aureus> 99.9%, Escherichia coli> 99.5%, Candida albicans> 97.1%. Ac...

Embodiment 2

[0048] Example 2: Moisture Wicking Antibacterial Business Socks

[0049] Weaving process: product name SEECOME silver ion antibacterial business socks, raw materials: 30 / 70 cross shaped silver antibacterial nylon covered yarn, 70D / 48F cross shaped silver antibacterial nylon, bamboo cotton fiber 32 S .

[0050] Raw material ratio: 44% cross shaped silver antibacterial nylon, 51% bamboo cotton fiber, 5% spandex.

[0051] Weaving machine: lonati Italian hosiery machine

[0052] Spandex-wrapped yarn first, using 30D spandex and 70D / 48F cross-shaped silver antibacterial nylon, with a stretch ratio of 3.5 times.

[0053] The lonati Italian hosiery machine is used to weave and shape.

[0054] After the head is sewn by hand, it is dyed brown at 95°C for 30 minutes, and the finished product is shaped by two steam pressures.

[0055] The socks were tested by the FZT73023-2006 antibacterial standard, washed 50 times, and the bacteriostatic rate was >99.9% for Staphylococcus aureus, >...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com