Improved rheology-modified grafts and adhesive blends

A rheological modification, adhesive technology, applied in the direction of graft polymer adhesives, adhesive types, adhesives, etc., can solve problems such as affecting interlayer adhesion and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

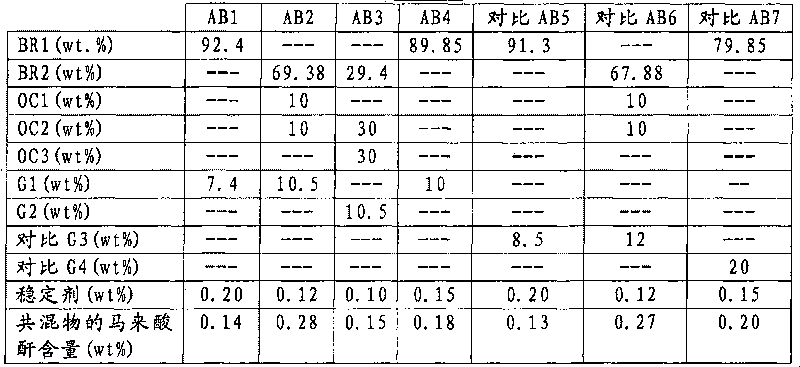

Embodiment 1 and comparative Embodiment 2

[0081] In order to demonstrate the improved results obtained with the inventive adhesive blends formulated using rheology-modified grafts with reduced relaxation times, the adhesive blend AB1 (inventive) and Comparative AB5 were evaluated as the tie layer in a 5-layer HDPE / tie layer / EVOH / tie layer / HDPE barrier film. 3 and 5-mil thick films were prepared on a Killion coextrusion line. The melt temperature at the die exit of the extruder was 210°C for the binder blend, 200°C for EVOH and 230°C for HDPE. The HDPE used for the film is a commercially available ethylene homopolymer (density 0.962 g / cm 3 ; MI 2g / 10min). EVOH is a commercial resin with an ethylene content of 32 wt% and a MFR of 3 g / 10 min.

[0082] Adhesion at the EVOH / HDPE interface was measured according to ASTM D 1876. Adhesion values obtained using adhesive blend AB1 of the present invention were 1.48 and 2.92 lbs / in for 3- and 5-mil films, respectively. For the films prepared using the comparative tie laye...

Embodiment 3 and comparative Embodiment 4

[0084] The ability to vary the composition of the inventive adhesive blends and obtain improved adhesion in oriented barrier films is demonstrated by these examples in which AB2 (inventive) and comparative AB6 were used as 3-mil thick 5-layer Tie layer adhesive in LLDPE / tie layer / EVOH / tie layer / LLDPE barrier film was evaluated. The LLDPE resin used has a density of 0.916g / cm 3 And MI is 1g / 10min ethylene-butene-1 copolymer. The EVOH resin was the same as that used in Example 1. Melt temperatures (at the die) for film coextrusion were 200°C (LLDPE); 230°C (EVOH) and 220°C (tie layer adhesive). To obtain oriented 3-mil thick films, 22 mil thick sheets obtained from the coextrusion line were stretched in the machine direction at 115°C. Some stretched films prepared in this manner were also irradiated at 5 Mrad to determine the effect of the radiation on adhesion. Barrier films are often irradiated in industrial operations. Irradiated and non-irradiated oriented films prepare...

Embodiment 3

[0086] Example 3 (film prepared using AB2):

[0087] Orientation - no radiation 1.15

[0088] orientation-radiation 1.39

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com