High-efficiency heat-radiation dynamic cell, temperature control system of electric vehicle and electric vehicle

A power battery and temperature control system technology, applied in battery temperature control, battery temperature regulation, secondary battery, etc., can solve problems such as short board effect, uneven distribution of temperature field, unbalanced performance of battery cells, etc., and achieve performance improvement , avoid burning or explosion, high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described below in conjunction with the accompanying drawings.

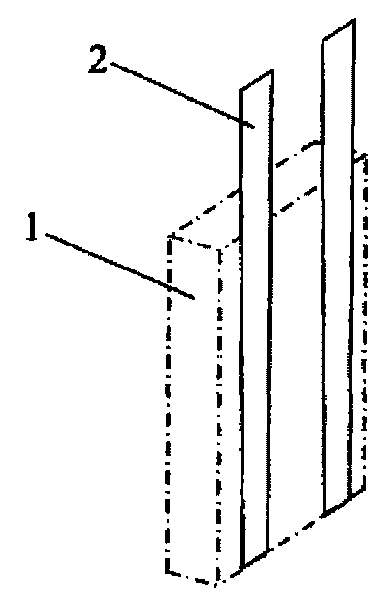

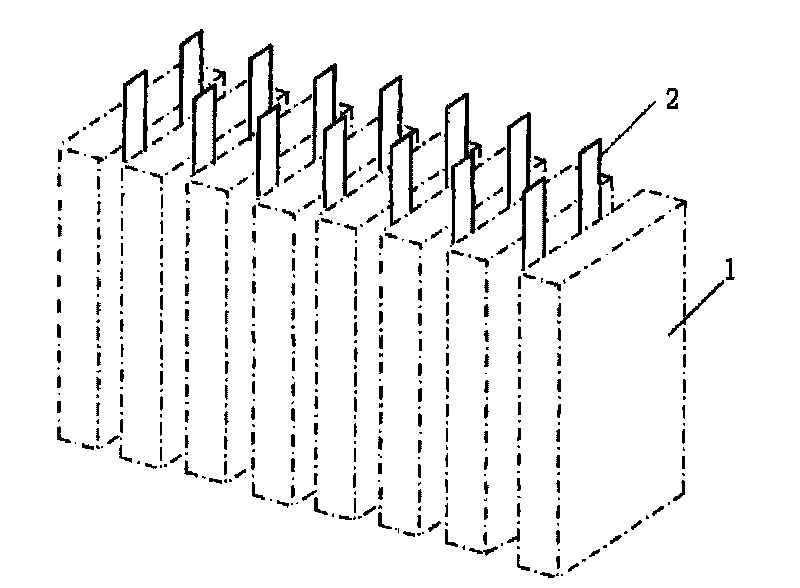

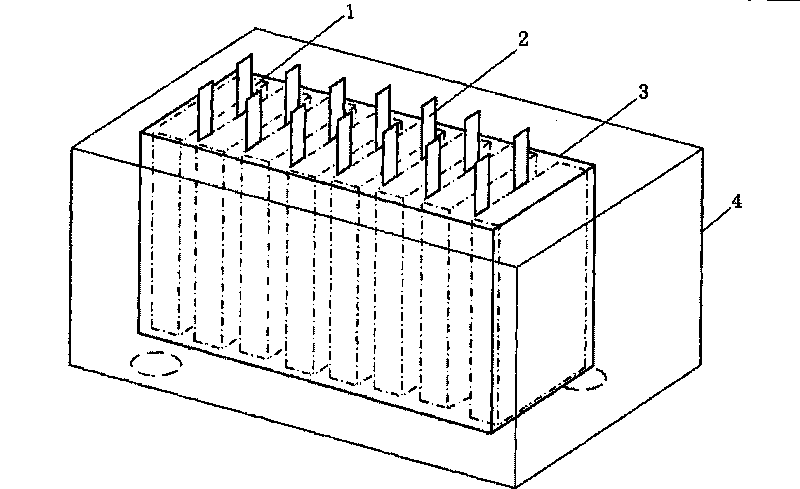

[0031] like figure 1 As shown, the power battery of the present invention includes a battery unit 1 and a flat heat pipe 2, figure 1 The flat heat pipe 2 is a flat heat pipe with a micro heat pipe array in it, that is, a flat heat pipe with a plurality of micro heat pipes arranged in parallel in the heat conduction plate entity by extrusion or stamping, and of course other types of flat heat pipes, And has a certain deformation performance, so as to become a curved or other shape that can fit the surface. The battery unit 1 is a single battery with a structurally strong casing, or a soft packaged battery assembly with a structurally strong casing outside which is composed of two or more soft-sealed single cells. The casing here refers to a hard casing. The flat heat pipe 2 is attached to the side of the battery unit 1. The side of the battery unit 1 is a plane in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com