Method for measuring niobium content in tungsten carbide added with niobium or simultaneously added with tantalum and niobium

A measurement method, tungsten carbide technology, applied in color/spectral characteristic measurement, analysis through chemical reaction of materials, material analysis through observation of the influence of chemical indicators, etc., can solve the problem of low measurement results and reproducibility No problem, low recovery rate, etc., to achieve the effect of good accuracy and reproducibility, high precipitation recovery rate, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The method for determining the content of niobium in tungsten carbide with niobium added or niobium and tantalum added simultaneously by spectrophotometry is described in detail below.

[0053] 1. Scope of application: This method is suitable for the determination of niobium content in tungsten carbide with niobium added or niobium and tantalum added at the same time. Measuring range: 0.010~2.000%.

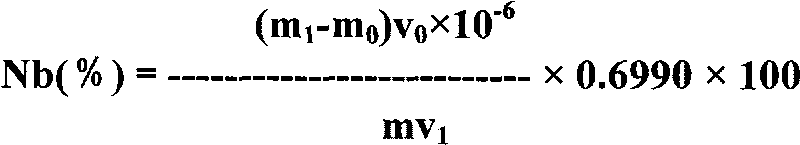

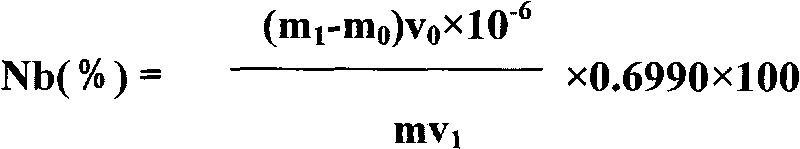

[0054] 2. Principle

[0055] After the sample is ground and sieved, it is melted with sodium peroxide, leached with hot water, precipitated by coprecipitant and secondary precipitation by tannic acid, and the niobium or niobium and tantalum are separated from the main body of tungsten and other impurities, and made into a tartaric acid solution , in the sulfuric acid medium, niobium and 5-Br-PADAP form a red chelate, and its color depth is proportional to the amount of niobium. Accordingly, the niobium content is determined by the photometric method according to the niobiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com