Test device for simulating and testing thermal fatigue failure of high-temperature part in real time

A technology for high-temperature components and test devices, applied to measuring devices, instruments, scientific instruments, etc., to achieve the effects of wide temperature range, fast heating and cooling rates, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention provides a test device for simulating and real-time testing of thermal fatigue failure of high-temperature components. The present invention will be further described below through the description of drawings and specific implementation methods.

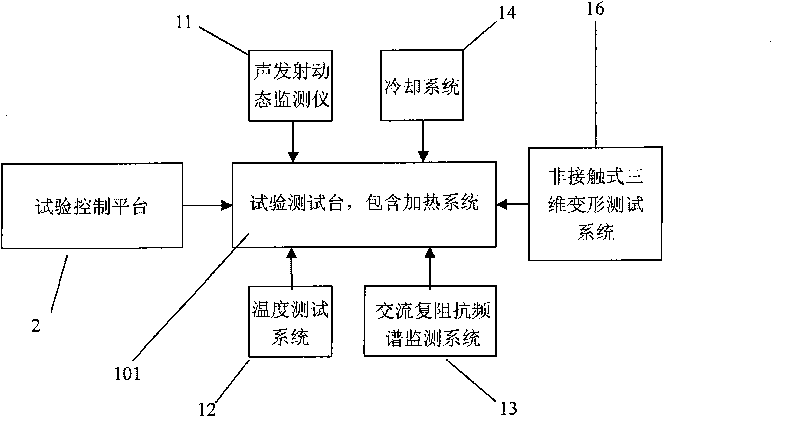

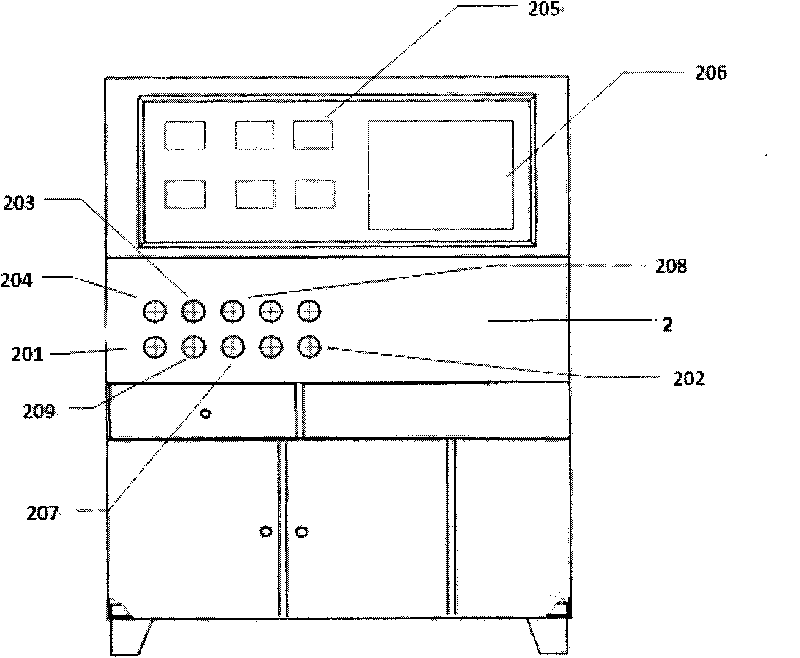

[0030] Such as figure 1 As shown, the structure of the test device includes: a test bench, a high-temperature gas bidirectional heating system connected to the test bench, a temperature test collection system 12, a cooling system 14, a non-contact three-dimensional deformation test system 16, and an acoustic emission non-destructive Detection system 11, AC complex impedance spectrum monitoring system 13, test control platform 2.

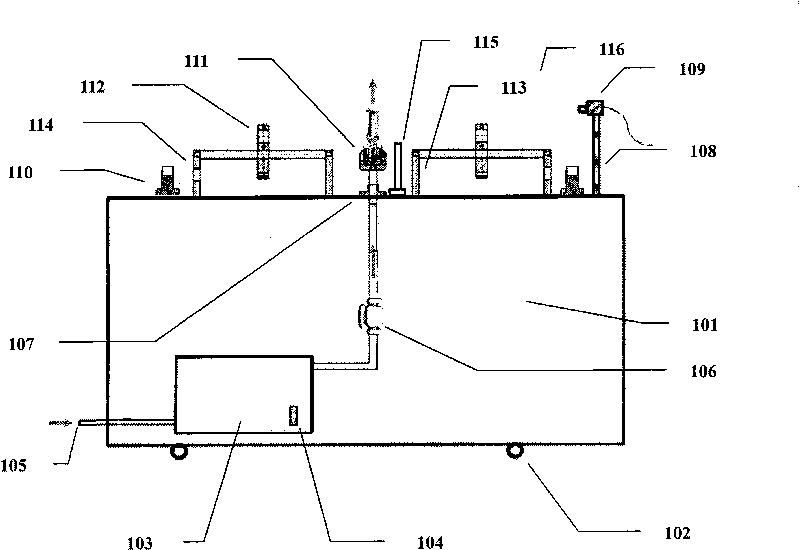

[0031] Such as figure 2 As shown, the structure of the test bench is as follows: a clamp 111 and a clamp fixture 107 for clamping the sample 5 are installed at the middle position on the test test platform 101, and the upper and lower positions of the clamp 111 are adjustable;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com