Supporting structure of beam type conversion layer template and method for strengthening substructure

A technology of formwork support and beam conversion, which is applied in the direction of building construction, formwork/formwork/work frame, and on-site preparation of building components, which can solve the unclear stress situation of support poles and increase the safety risk of support systems , The impact of the lower floor is not fully considered to achieve the effect of improving the quality of the project, enhancing the bearing capacity, and speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

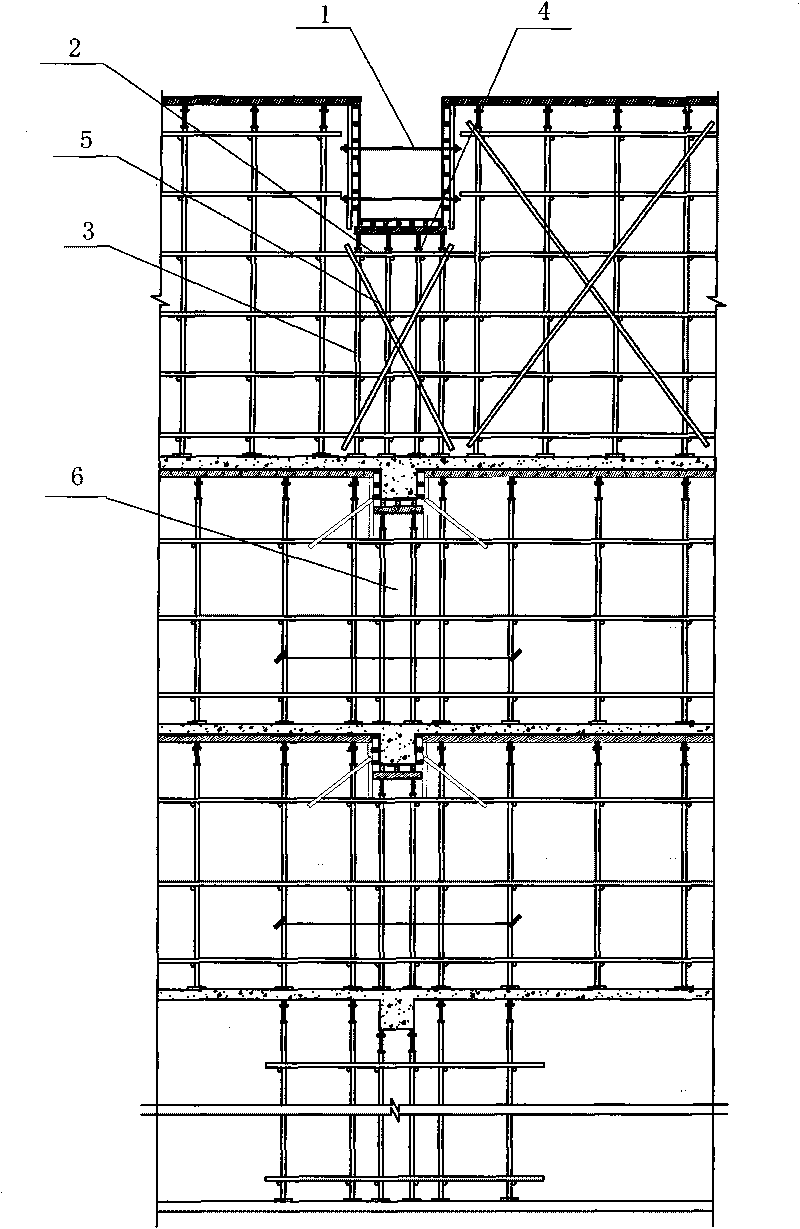

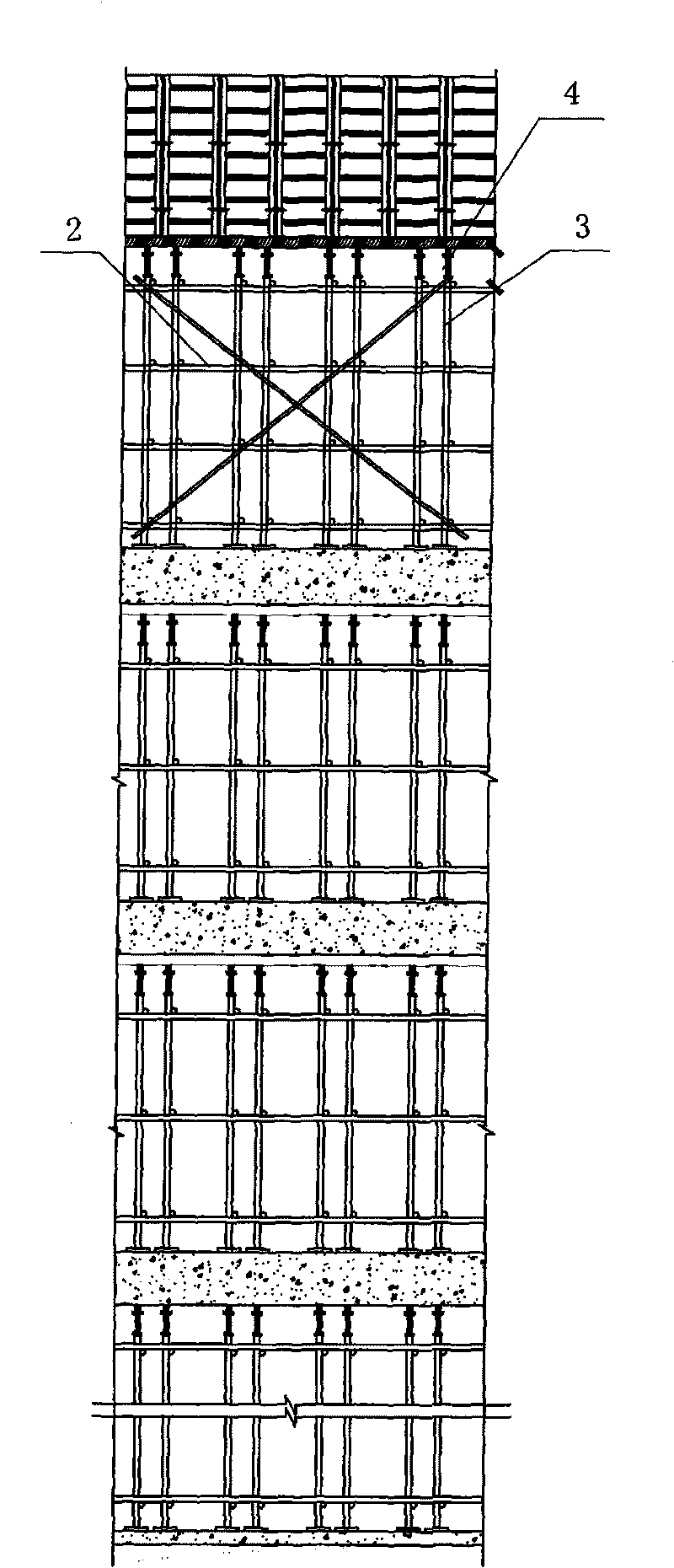

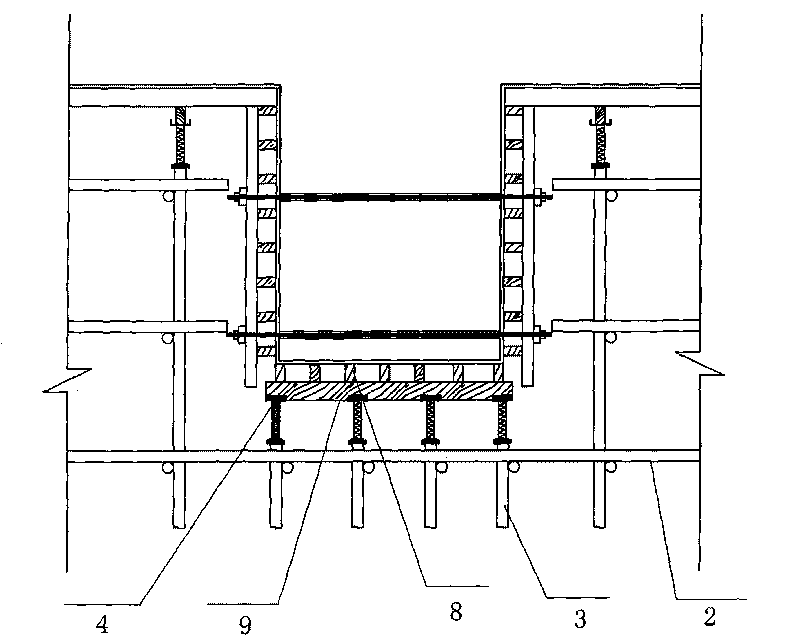

[0019] Such as figure 1 , 2 , 3, a beam-type conversion layer formwork support structure, under the beam bottom formwork 1, vertical bars 3 and cross bars 2 that are fixedly connected together are also independently arranged under the beam bottom formwork 1, and the vertical bars 3 The top is provided with an adjustable jacking 4, and between the adjustable jacking 4 and the beam bottom formwork 1, a wooden main flute 9 and a wooden second flute 8 are arranged. Bottom formwork 1 contacts, and the wooden square main flute 9 is positioned on the vertical bar 3, contacts with adjustable top bracket 4.

[0020] The vertical rods 3 are evenly distributed under the beam bottom template 1, and cross bars 5 are arranged between the vertical rods 3; the cross rods 5 are crossed in pairs, and the two ends of each cross rod 5 are respectively connected to the two farthest relative positions. The pole top and the pole bottom of root pole 3.

[0021] The specific arrangement is as follo...

Embodiment 2

[0025] Such as figure 1 , 2 As shown, a method for strengthening the lower structure of the beam-type transfer floor formwork support, which encrypts the lower floor support corresponding to the frame support beam support, and the encryption range 6 is within 800mm of the frame support beam and both sides; 2 The formwork support of the first floor is also reinforced at the position corresponding to the conversion floor beam on the next floor.

[0026] Removal of the above-mentioned support reinforcement: When the solid concrete strength of the mass concrete transfer beam reaches 100%, all the supports of the corresponding positions at the lower part of the transfer beam can be removed except the transfer layer. The corresponding formwork support can be dismantled after the concrete strength reaches the requirement in other beam and slab parts of the transfer floor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com