Vanadium dioxide precursor liquid and method for preparing thin-film material by using the same

A technology of vanadium dioxide and precursor liquid, which is applied in metal material coating process, solid-state chemical plating, coating, etc., can solve the problems of unfavorable large-scale production, difficult control of alkoxide hydrolysis, and poor process controllability, etc. Achieve the effect of reducing raw material cost, increasing operability and repeatability, and simplifying heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

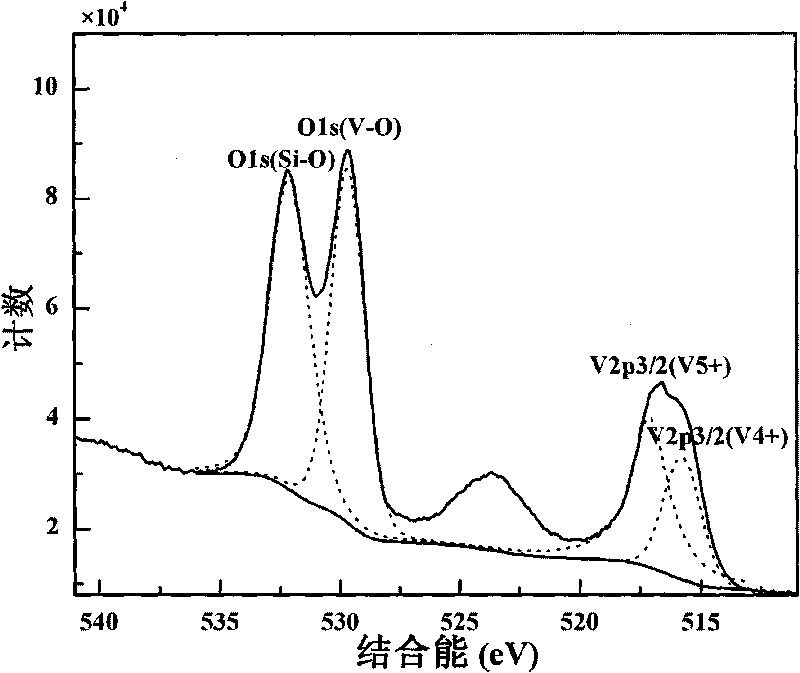

Image

Examples

Embodiment 1

[0070] Example 1 Preparation of vanadium dioxide precursor solution with vanadium pentoxide as raw material

[0071] 1. Add 0.182g of vanadium pentoxide to 15ml of deionized water, add concentrated ammonia water to adjust the pH value to 9.5 or above, stir and maintain the pH value, and the vanadium pentoxide is completely dissolved.

[0072] 2. Add 5 ml of 10% polyvinyl alcohol (molecular weight: 50,000) aqueous solution to it to obtain a precursor solution.

Embodiment 2

[0073] Example 2 Preparation of tetravalent vanadium dioxide precursor solution using vanadium pentoxide as raw material

[0074] 1. Add 0.182g of vanadium pentoxide to 20ml of deionized water, alternately add hydrochloric acid and hydrazine hydrate dropwise to keep the pH of the system at about 1.0, and stir until the system becomes a transparent blue solution.

[0075] 2. Add 0.6 g of polyethylene glycol (molecular weight: 3000) to the solution obtained in 1, and fully dissolve to obtain a precursor solution.

Embodiment 3

[0076] Example 3 Using vanadium pentoxide as a raw material to prepare a vanadium dioxide precursor solution doped with tungsten

[0077] 1. Add 0.182g of vanadium pentoxide to 20ml of deionized water, then adjust the pH value to 9.5 or above with ammonia water, stir and maintain the pH value, and the vanadium pentoxide is completely dissolved.

[0078]2. In order to keep the solution stable, add 0.15g citric acid therein.

[0079] 3. Under vigorous stirring, add 0.1ml of ammonium tungstate ((NH 4 ) 6 h 2 W 12 o 40 ·XH 2 O) Aqueous solution.

[0080] 3. Add 5ml of ethylene glycol to it to adjust the viscosity to obtain the precursor solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com