Buffering splash-protection dovetail molten iron trough of pig machine

A dovetail-shaped, anti-splash technology, which is applied to casting equipment, equipment for feeding molten metal into molds, metal processing equipment, etc., can solve problems that affect the service life of cast iron molds, serious slag accumulation in splash areas, and harsh working environments , to achieve the effects of reducing production and maintenance costs, improving the working environment, and reducing splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

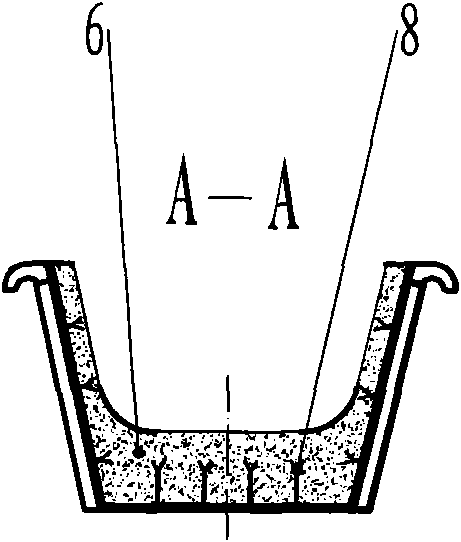

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] As shown in the figure, the buffer and anti-splash dovetail iron launder of the cast iron machine includes the first buffer iron launder 3, the middle transitional iron launder 4 and the tail dovetail iron launder 7, and their shells are all low carbon steel plates It is welded, the inner wall of the groove is welded with anchor nails 8, and the refractory lining 6 is poured.

[0013] The molten iron ladle 1 is lapped on the front pillar 2 and tipped over slowly. The molten iron in the molten iron ladle 1 flows into the first buffer type iron receiving trough 3, and the first buffer type iron receiving trough 3 is installed between the molten iron tank and the middle transitional molten iron launder 4 During the period, the molten iron is poured in the first buffer type iron receiving trough to form a molten pool, and the buffered molten iron flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com