Double-layer electrode for multi-level depressed collector and preparation process thereof

A double-layer electrode, preparation process technology, applied in electrode system manufacturing, cold cathode manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as the inability to effectively ensure the gas-tight connection of pyrolytic graphite and hinder the widespread use of pyrolytic graphite. , to achieve high firmness, increase thermal conductivity, and inhibit secondary electron emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The multi-stage step-down collector is a key component of various traveling wave tubes and some klystrons. Its function is to recover the remaining kinetic energy in the electron beam after beam-wave interaction, thereby greatly improving the overall efficiency of the device.

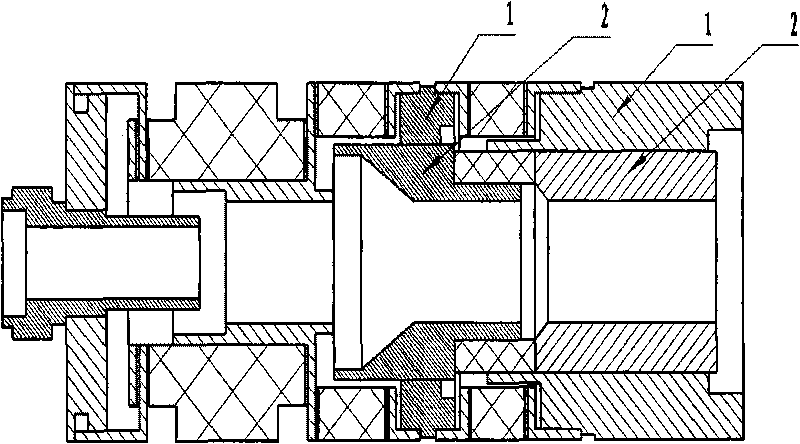

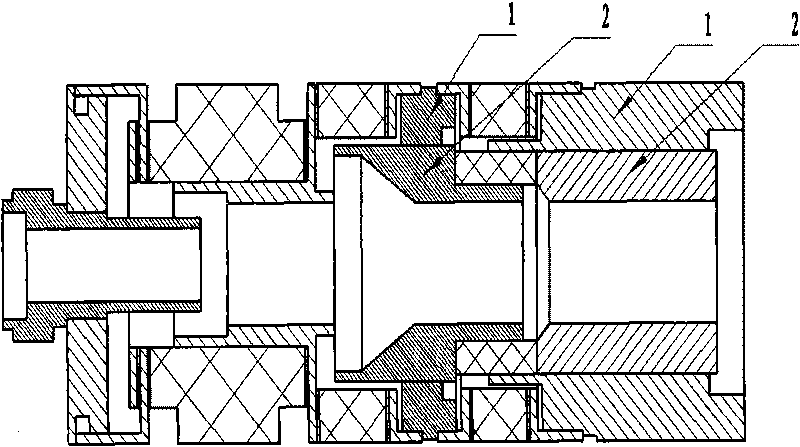

[0049] Such as figure 1 As shown, it is a multi-stage step-down collector double-layer electrode of the present invention, including a metal layer 1 and a graphite layer 2, and the opposite surfaces of the two layers are tightly bonded. The material of the metal layer 1 can be oxygen-free copper or other metals. The material of the graphite layer 2 is pyrolytic graphite or high-density isotropic graphite.

[0050] The multi-stage step-down collector double-layer electrode of the present invention is a double-layer electrode that combines pyrolytic graphite or high-density isotropic graphite layer 2 with other metal layers 1, and can utilize the electrode outer layer metal layer 1 to ensure the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com