Circulating fluidized bed boiler hearth with grand-cross penetrating middle wall structure

A circulating fluidized bed and boiler furnace technology, which is used in fluidized bed combustion equipment, steam boilers, and molten fuels, etc., can solve problems such as the expansion of the heating surface being limited to a certain extent, and reduce impact and wear. , The effect of strong shock resistance and high physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

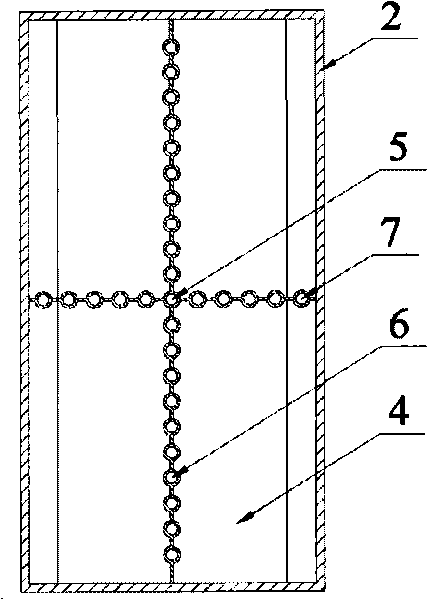

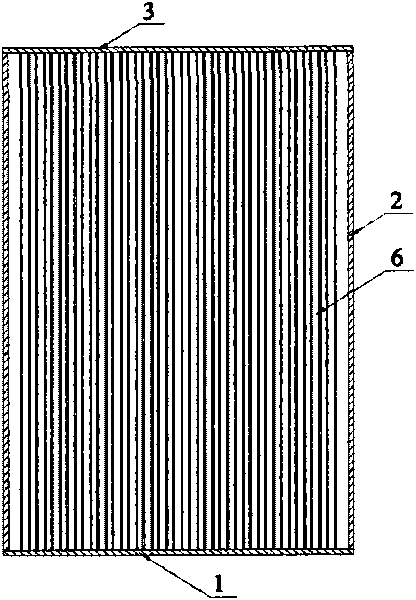

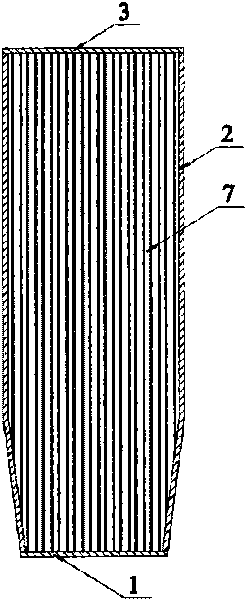

[0016] The circulating fluidized bed boiler furnace with a large cross penetrating through the middle partition wall structure includes air distribution plate 1, water cooling wall 2, ceiling 3, circulating fluidized bed boiler furnace 4, circulating fluidized bed boiler furnace 4 is surrounded by water cooling walls 2, circulation The upper end of the fluidized bed boiler furnace 4 is provided with a ceiling 3, the lower end of the circulating fluidized bed boiler furnace 4 is provided with an air distribution plate 1, and the circulating fluidized bed boiler furnace 4 is provided with a cross through the middle partition wall 5, and the cross through the middle partition wall 5 comprises a vertically arranged width direction partition wall 6 and a depth direction partition wall 7, and the large cross runs through the partition wall 5. The vertical direction is the same as the furnace height, and the width and depth directions are the same as the furnace width and depth. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com