Polygonal thin-oil rubber sealed gas holder

A technology of rubber sealing and gas tank, applied in the field of gas tank sealing device, polygon thin oil rubber sealing gas tank-POR type gas tank, can solve the problems of large leakage rate of sealing oil, short service life of sealing device, large leakage of sealing oil, etc. , to achieve the effect of good sealing performance, less welding workload, improved and pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

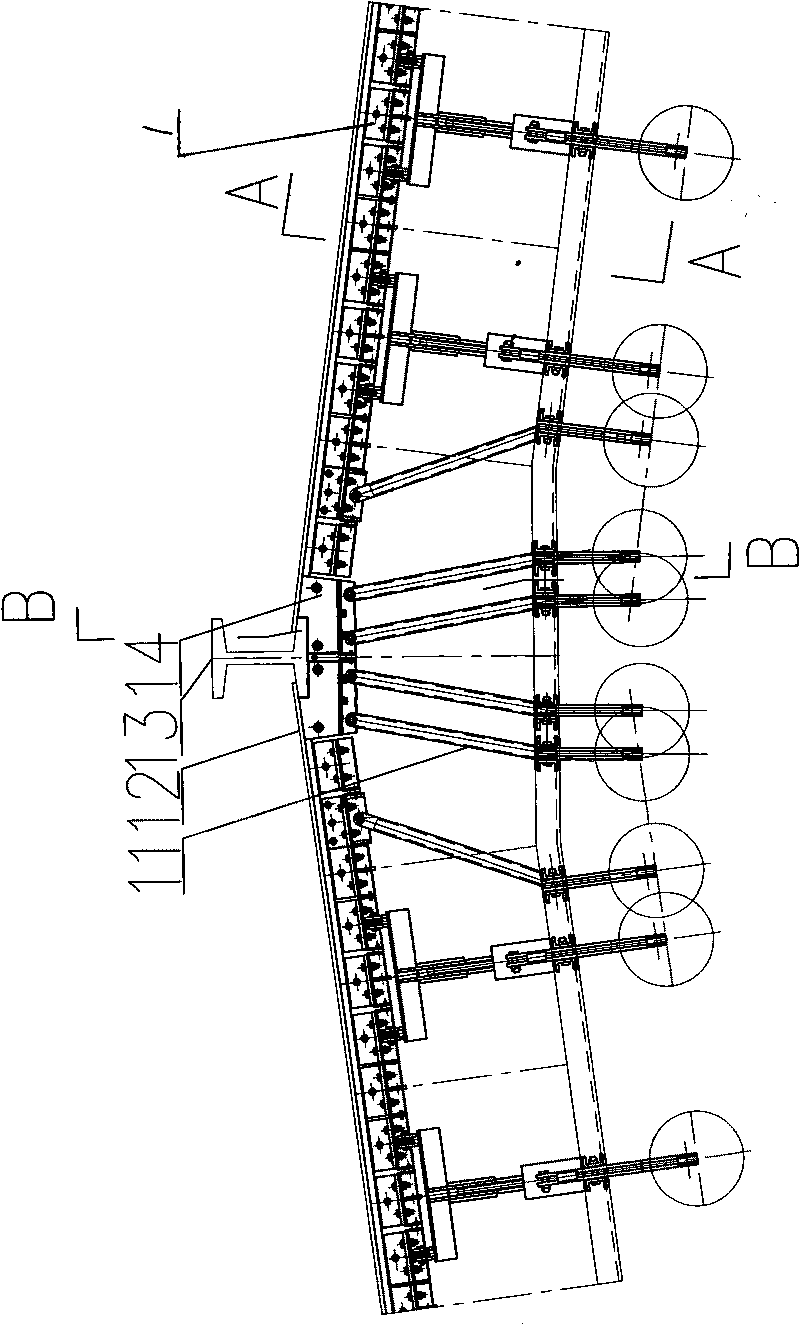

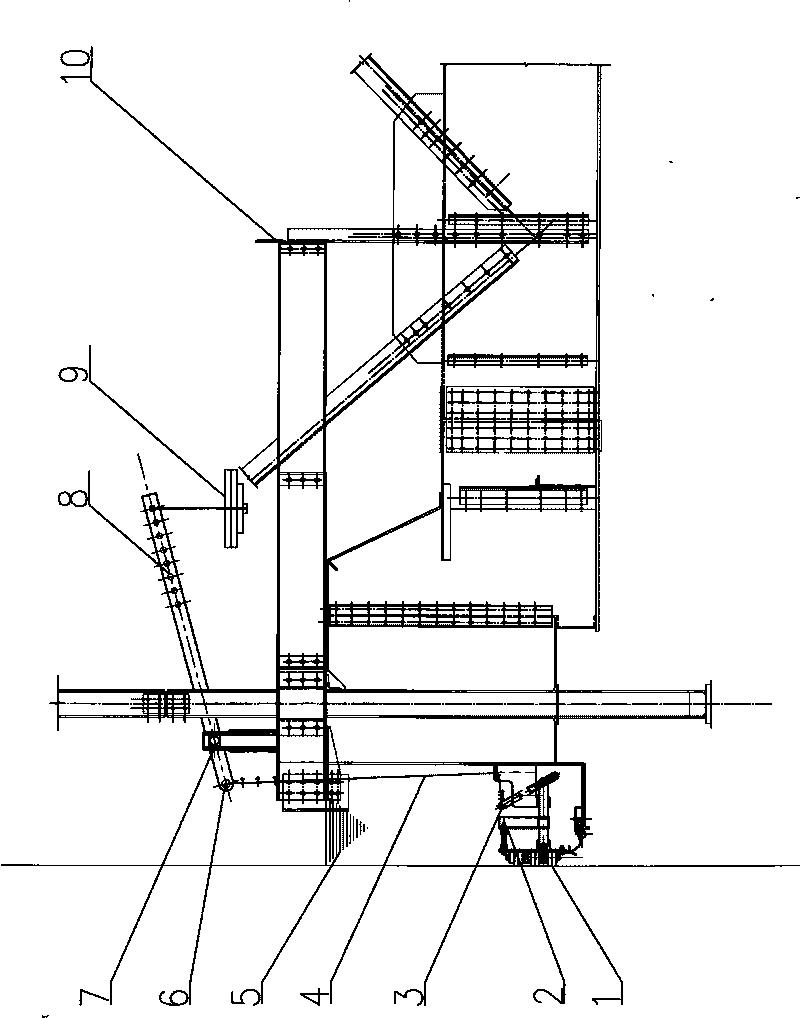

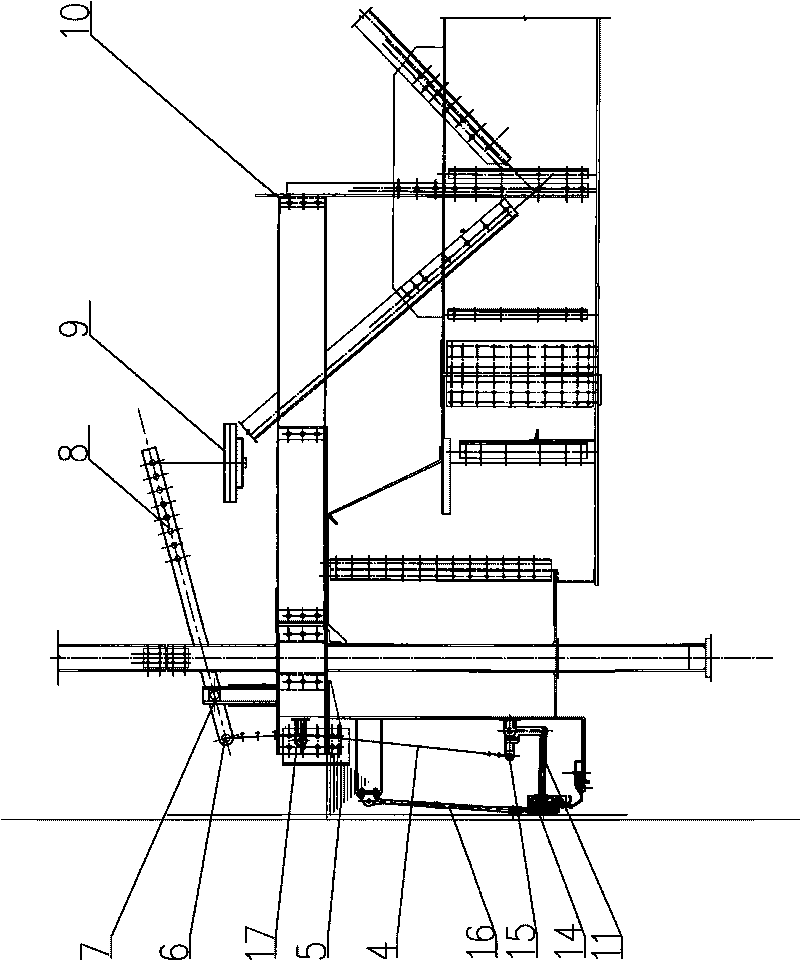

[0014] The side plate 12 is welded on the column 13 . The sealing system 1 is installed in the piston oil groove 5, and is pressed on the side plate 12 by the anti-turnover system 2; the connection system 4 connects the first-stage afterburner system (using a lever plus slider mechanism) 3 and the second-stage afterburner system ( Adopt lever mechanism) 6; Lever support 7 is installed on the piston 10 and supports the second stage afterburning system (adopting lever mechanism) 6; On the weight hook point 8 on the second stage afterburning system (adopting lever mechanism) 6 Hang adjustable weights 9. The sealing system 1 mainly consists of three sets of sealing rubber rings and canvas.

[0015] The corner slider sealing system 14 is arranged on both sides of the corner of the column 13, which is mainly composed of three sets of sealing rubber ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com