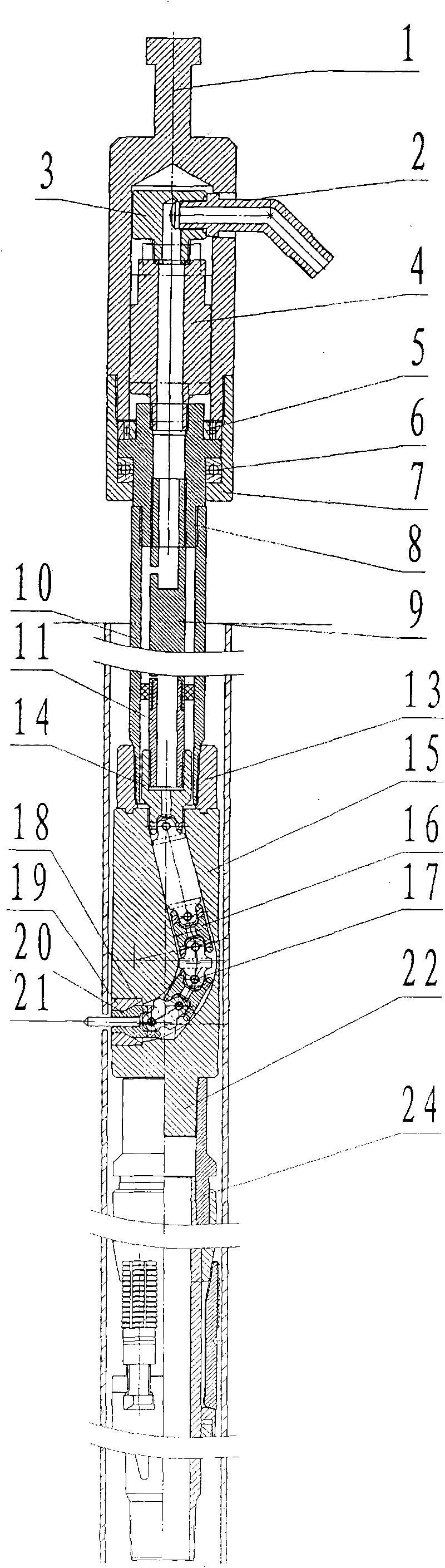

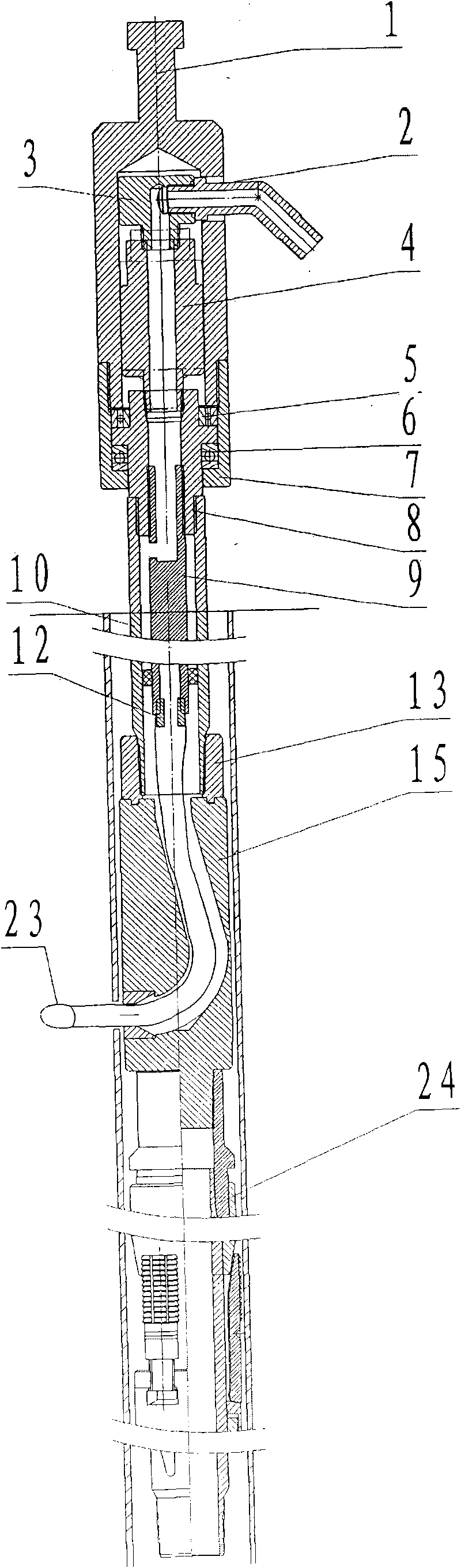

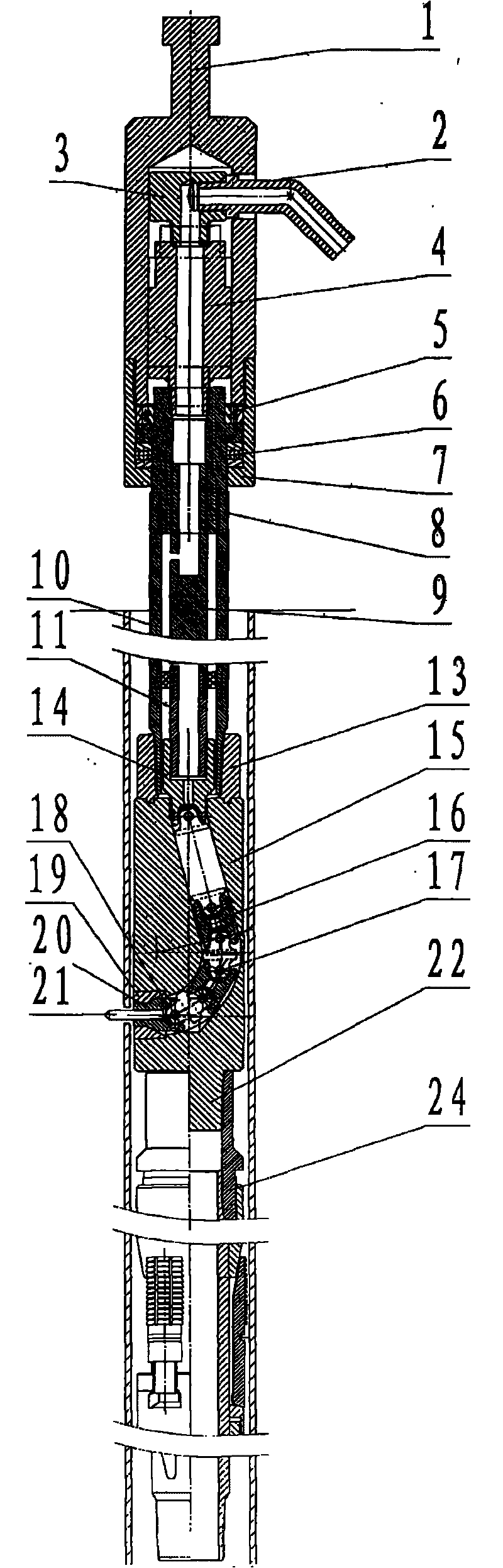

Ultra-short radius radial well-drilling tool system

An ultra-short radius and radial drilling technology, which is applied in directional drilling and liquid/gas jet drilling, etc., can solve the problems of low pressure coefficient and poor economy in the main block, and achieve long horizontal wellbore and high recovery , The effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In the accompanying drawings, the ultra-short radius radial drilling tool system is composed of two parts: the casing opening system and the high-pressure injection system; Rotary joint 4, thrust ball bearing 5, single row radial ball bearing 6, base 7, center pipe 8, sucker rod 9, oil pipe 10, screw rod 11, high-pressure rubber hose 12, fixed upper joint 13, universal joint upper joint 14, Guide rail groove 15, universal joint 16, shaft pin 17, cross joint 18, drilling template 19, drilling tool joint 20, drilling tool 21, lower joint 22, high pressure nozzle 23, positioning anchor 24; in ultra-short radius radial drilling In the tool system, the high-pressure injection system is to add two components of high-pressure rubber hose and high-pressure nozzle to the whole system; the outlet of the ground high-pressure pump is threaded with the elbow joint 2 of the liquid inlet, and the center pipe 8 is threaded with the sucker rod 9 and the oil pipe 10 Connection, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com