Construction technique for filling polyurethane hard bubbles in wall outer insulation layer

A technology of polyurethane rigid foam and construction technology, which is applied in the direction of heat preservation, walls, building components, etc. It can solve the problems of water seepage, freezing and thawing and falling off, easy cracking of board seams, and difficulty in guaranteeing the service life of the outer insulation layer, etc., and achieves dispersion of internal stress , Eliminate the cracking of the board seam, and the effect of strong self-adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

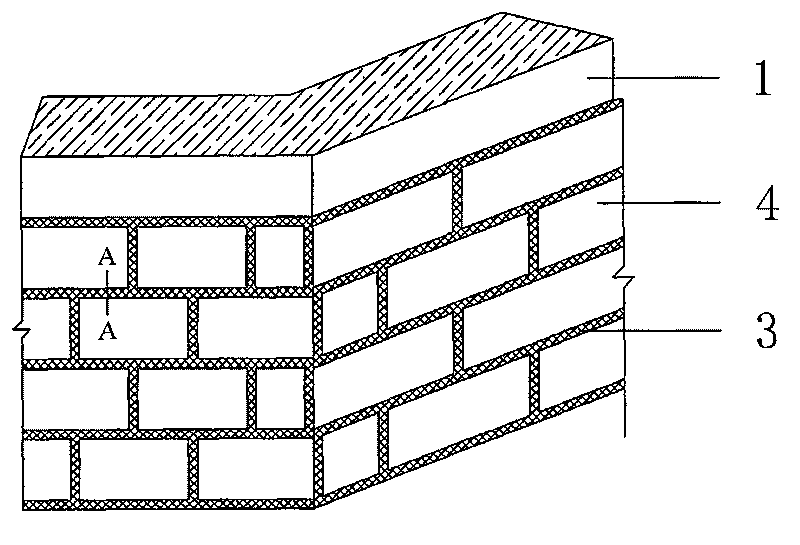

[0024] The construction process of pouring polyurethane rigid foam into the external insulation layer of the wall, the process steps are as follows:

[0025] (1) Base wall treatment, remove floating ash, floating soil, oil stains and other wastes on the surface of the base wall that hinder the sticking of insulation boards;

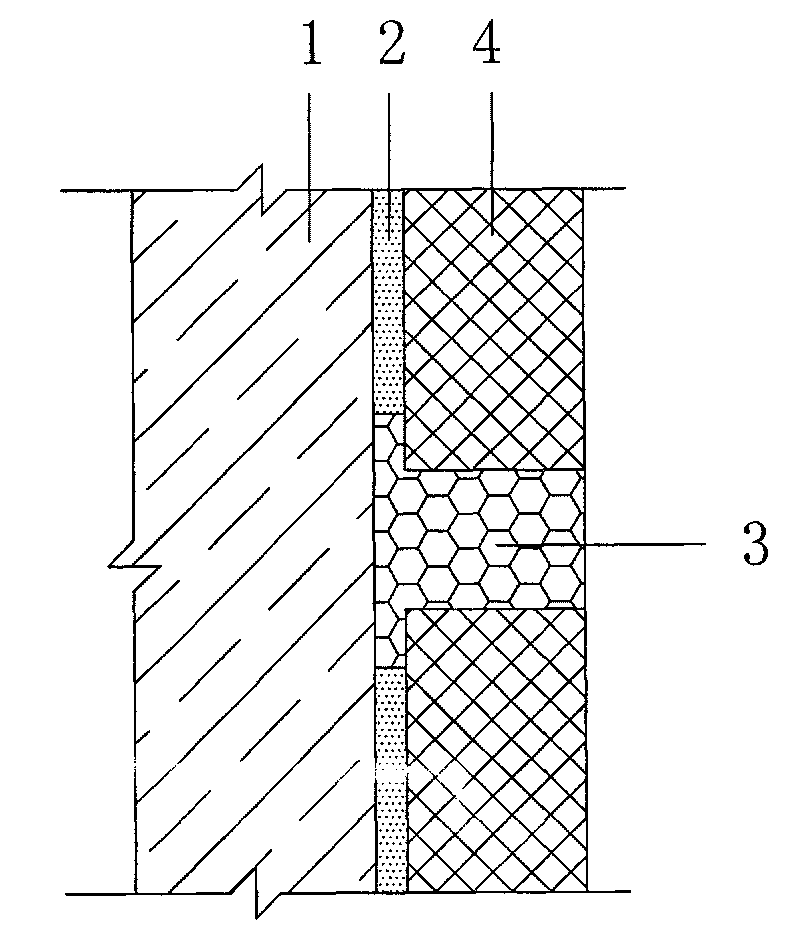

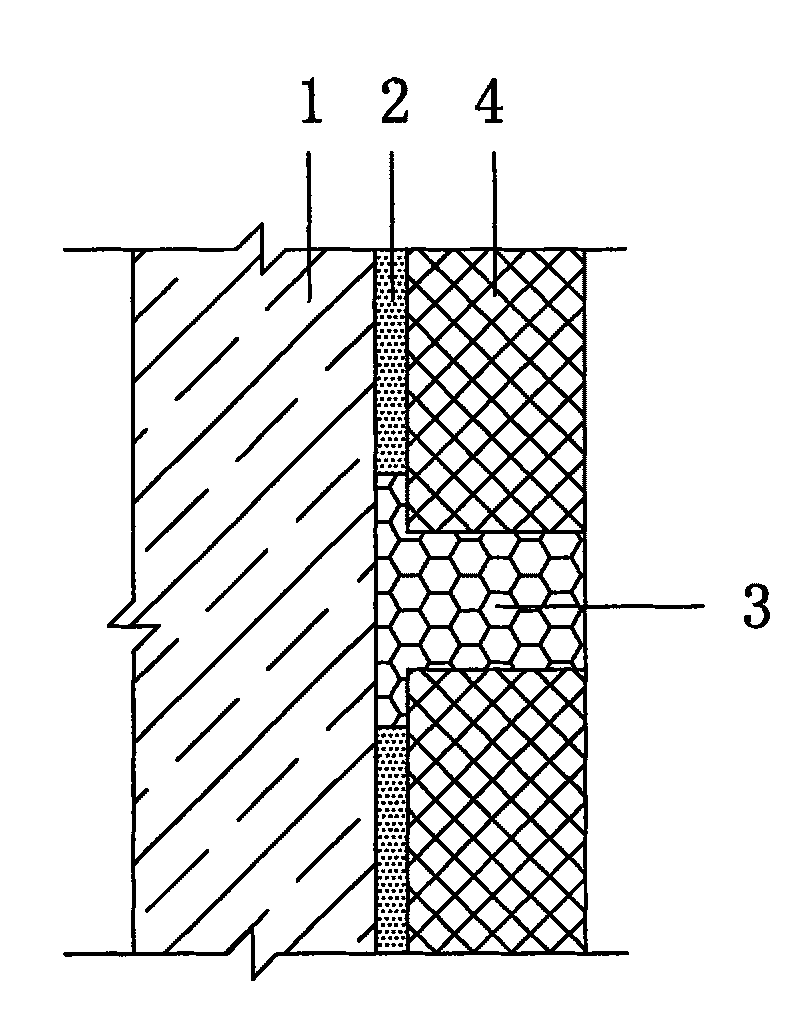

[0026] (2) Use an adhesive to paste the polystyrene board on the base wall. When pasting, make the adhesive between the polystyrene board and the base wall leave a distance of 10mm from the surrounding edges of the polystyrene board, and the polystyrene boards are mutually There is also a gap of 30mm between them;

[0027] (3) When the strength of the adhesive for pasting the polystyrene board reaches more than 60% of the design strength, inject hard polyurethane foam into the gap of the polystyrene board reserved above, so that the polyurethane foams in the gap and fills up the gap;

[0028] (4) the outer surface of the hard polyurethane foam after foam...

Embodiment 2

[0031] Embodiment two is basically the same as embodiment one, and its difference is that in step (2), the adhesive between the polystyrene board and the base wall has a distance of 20mm from the surrounding edges of the polystyrene board, and the polystyrene board There is also a gap of 50mm between each other;

Embodiment 3

[0033] Embodiment three is basically the same as embodiment one, except that in step (2), the adhesive between the polystyrene board and the base wall has a distance of 25 mm from the surrounding edges of the polystyrene board, and the polystyrene board There is also a gap of 60mm between each other;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com