A kind of polyurethane synthetic resin for preparing non-trace adhesive tape and non-trace adhesive tape prepared by using it

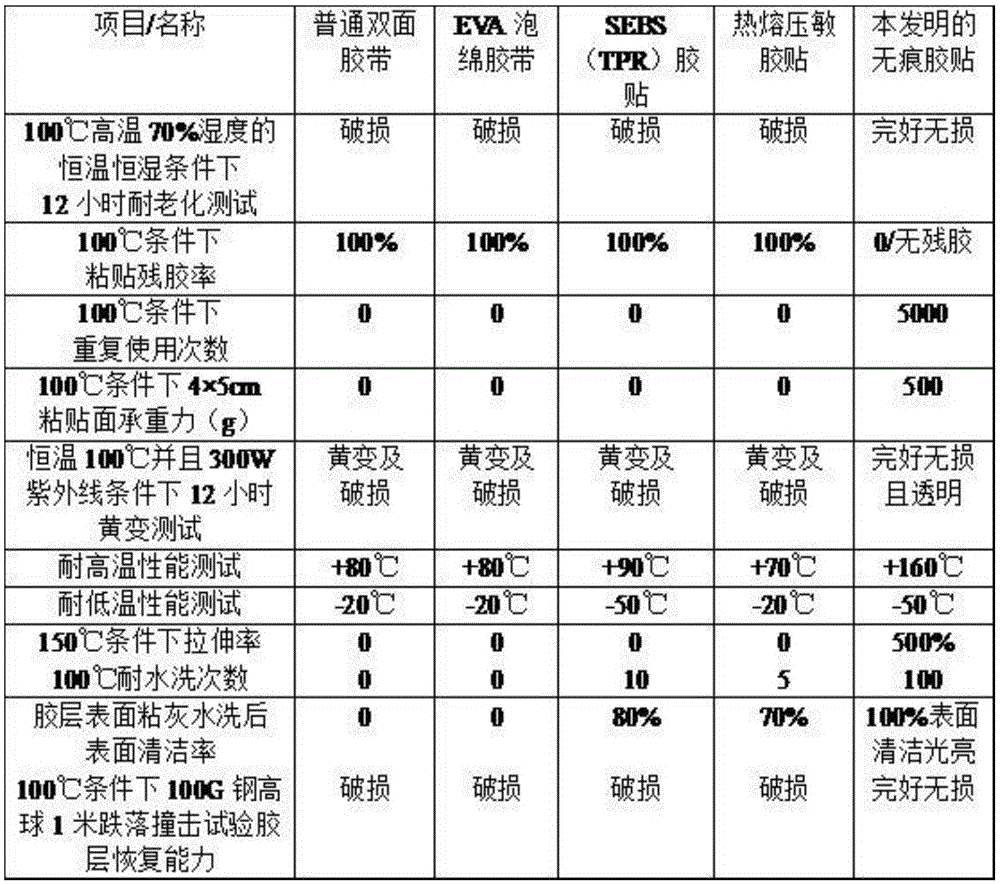

A technology of synthetic resin and polyester resin, applied in the direction of polyurea/polyurethane adhesive, polyether adhesive, film/sheet adhesive, etc., which can solve the problem of poor surface flatness and non-marking Paste, difficult to cure and other problems, to achieve good colloid resilience and recovery ability, good colloid ultra-high density performance, reduce energy loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A polyurethane synthetic resin for preparing non-trace adhesive stickers, which includes the following raw materials in parts by weight: 41 parts of polyether polyol resin, 10 parts of acrylic resin, 4 parts of unsaturated polyester resin, 2 parts of phenolic resin, and 1.5 parts of polycarbonate 0.8 parts of natural resin, 3 parts of amino resin, 4 parts of epoxy resin, 7 parts of silicone resin, 3 parts of isocyanate, 20 parts of curing agent, 4 parts of tackifier, and 0.3 parts of leveling agent. Wherein, the natural resin is a mixture of rosin and starch resin in any proportion; the curing agent is polyetheramine; the catalyst is a double metal cyanide complex catalyst; the tackifier is a silane coupling agent; The leveling agent is solvent-free polyurethane.

[0040] A method for preparing a polyurethane synthetic resin for non-trace adhesive stickers, the preparation method is as follows: mix raw materials in parts by weight, put them in a reaction kettle at 120°C...

Embodiment 2

[0046] A polyurethane synthetic resin for preparing non-trace adhesive stickers, which includes the following raw materials in parts by weight: 30 parts of polyether polyol resin, 8 parts of acrylic resin, 5 parts of unsaturated polyester resin, 1 part of phenolic resin, and 1 part of polycarbonate 1 part of natural resin, 4 parts of amino resin, 3 parts of epoxy resin, 8 parts of silicone resin, 4 parts of isocyanate, 30 parts of curing agent, 0.5 parts of catalyst, 5 parts of tackifier, and 0.3 parts of leveling agent.

[0047] Wherein, the natural resin is starch resin; the curing agent is polyether amine; the catalyst is a double metal cyanide complex catalyst; the tackifier is a silane coupling agent; Solvent polyurethane.

[0048] A method for preparing a polyurethane synthetic resin for non-trace adhesive stickers, the preparation method is as follows: mix raw materials in parts by weight, put them in a reaction kettle at 140°C, and react for 80 minutes while stirring t...

Embodiment 3

[0054] A polyurethane synthetic resin for preparing non-trace adhesive stickers, which includes the following raw materials in parts by weight: 51 parts of polyether polyol resin, 5 parts of acrylic resin, 3 parts of unsaturated polyester resin, 3 parts of phenolic resin, 2 parts of polycarbonate 0.7 parts of natural resin, 2 parts of amino resin, 5 parts of epoxy resin, 5 parts of silicone resin, 5 parts of isocyanate, 15 parts of curing agent, 0.9 parts of catalyst, 2 parts of tackifier, 0.4 parts of leveling agent, PU 0.1 parts of color paste.

[0055] Wherein, the natural resin is rosin; the curing agent is polyetheramine; the catalyst is a double metal cyanide complex catalyst; the tackifier is a silane coupling agent; Polyurethane.

[0056] A method for preparing a polyurethane synthetic resin for non-trace adhesive stickers, the preparation method comprises: mixing raw materials in parts by weight, putting them in a reaction kettle at 130°C, and reacting for 80 to 120 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com