Manufacturing method of polarizer

A manufacturing method and polarizer technology, which is applied in the field of polarizer manufacturing, can solve problems such as peeling off of protective film and degradation of polarization performance, and achieve the effects of suppressing decurling, excellent optical properties and adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

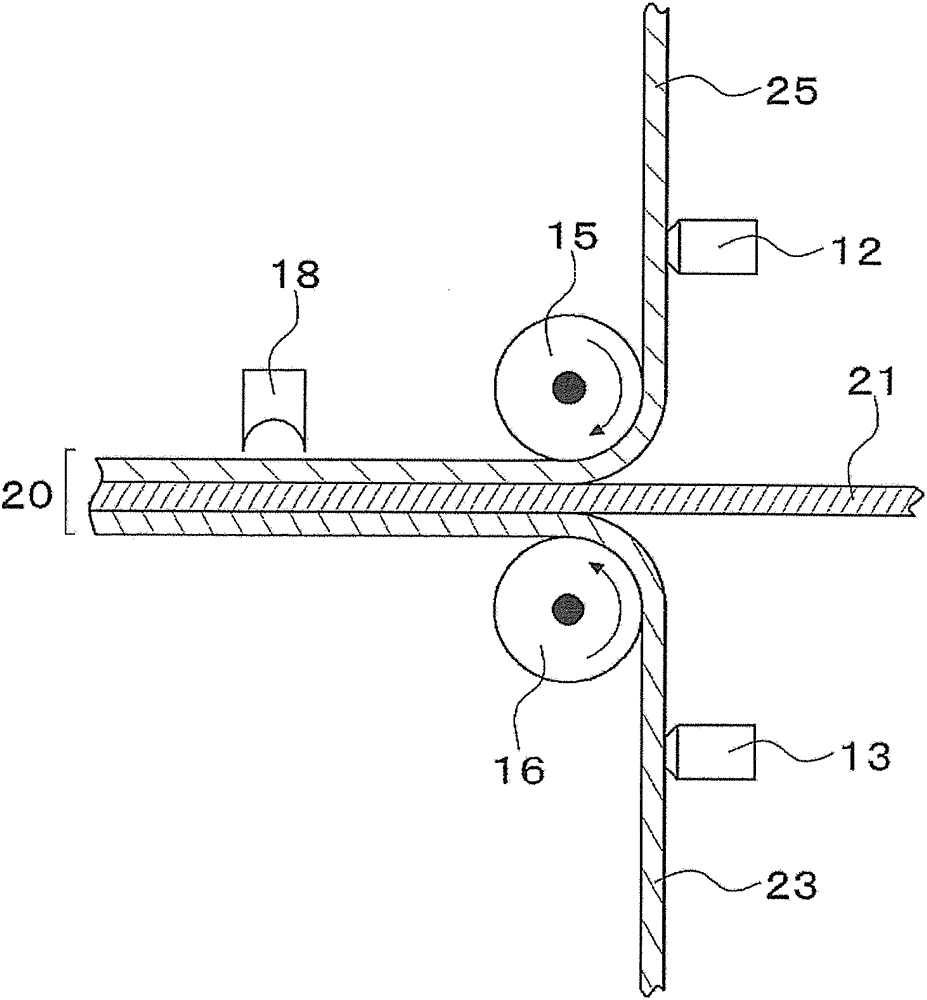

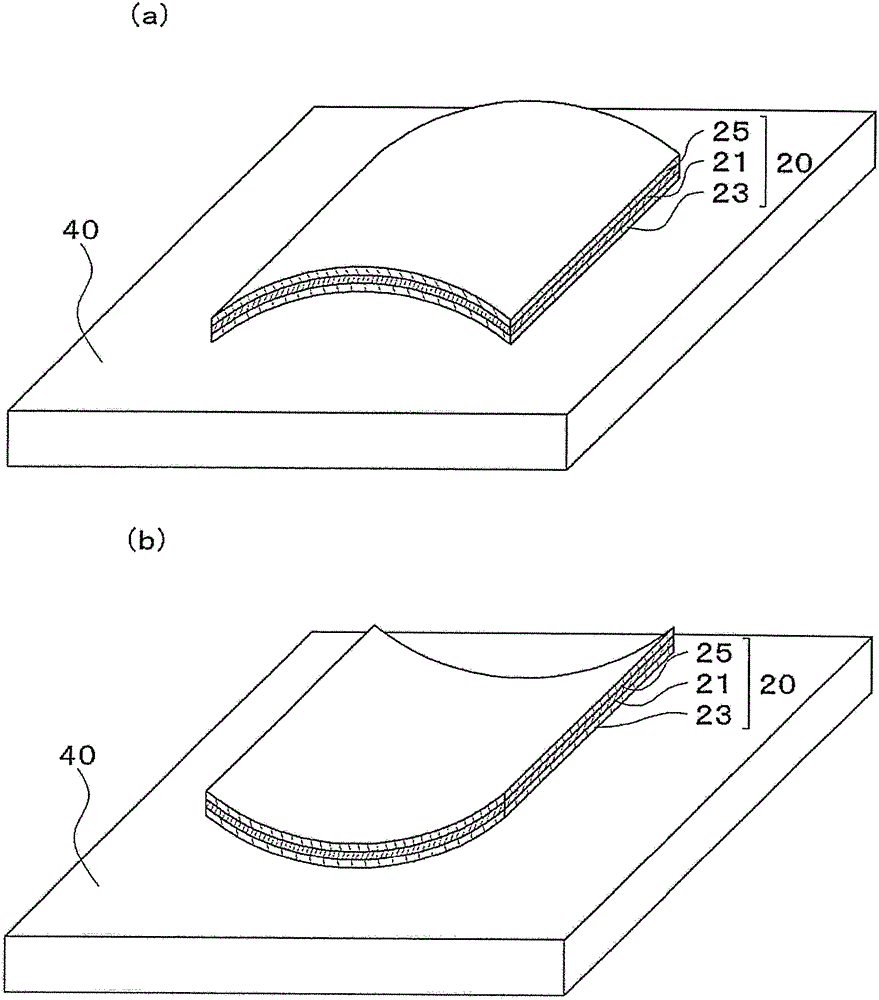

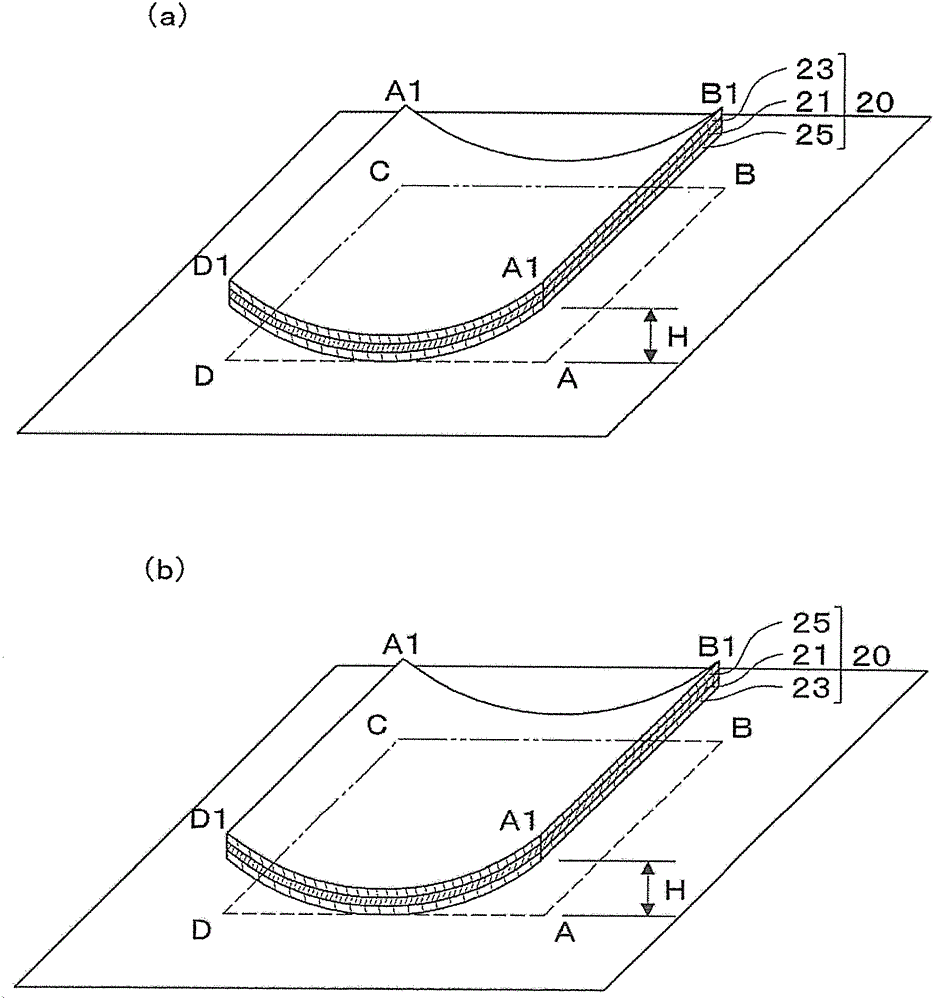

[0061] In the present embodiment, the acrylic resin film 25 is pasted so that the ratio of the pre-sticking tension per unit cross-sectional area of the acrylic resin film 25 to the pre-sticking tension per unit cross-sectional area of the transparent resin film 23 is 1 or more. That is, by applying a higher tension to the acrylic resin film 25 than the transparent resin film 23, a larger shrinkage stress is generated in the acrylic resin film 25, and excessive decurling is suppressed. Here, tension before sticking can be imparted by stretching the film before sticking in a direction along the transport direction of the film. Specifically, for example, a winding roll (not shown) that winds the polarizing plate 20 in a roll shape has a greater winding force than a delivery roll (not shown) of the acrylic resin film 25 in the form of a delivery roll. The method of winding force makes the rotation speed of the two rollers different.

[0062] Here, the pre-sticking tension pe...

Embodiment 1

[0188] (a) Manufacture of acrylic resin film

[0189] (acrylic resin and acrylic elastic polymer particles)

[0190] Let the copolymer whose weight ratio of methyl methacrylate / methyl acrylate be 96 / 4 be an acrylic resin. In addition, it is an elastomer particle with a three-layer structure, the innermost layer contains a hard polymer that is a copolymer of methyl methacrylate and a small amount of allyl methacrylate, and the middle layer contains butyl acrylate as a main component. A soft elastomer of ester, a copolymer of styrene and a small amount of allyl methacrylate, the outermost layer consists of a hard polymer that is a copolymer of methyl methacrylate and a small amount of ethyl acrylate, Particles having an average particle diameter of 240 nm up to the elastomer as the intermediate layer were used as acrylic elastic polymer particles.

[0191] (production of acrylic resin film)

[0192] The acrylic resin and the acrylic elastic polymer particles were mixed in a w...

Embodiment 2

[0203] In (c) of Example 1, set the peripheral speed ratio R 2 / R 1 It was 1.0107, and other polarizing plates were produced in the same manner as in Example 1. The amount of curl of the obtained polarizing plate was measured by the same method as (d), and it was found that the cyclic olefin resin film side was a concave reverse curl, and the maximum value was -79.0 mm. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com