Single-component modified high chlorinated polyethylene weathering resistant residual rust painting

A technology of high-chlorinated polyethylene and rust-coated coatings, which is applied in the direction of anti-corrosion coatings and coatings, and can solve problems such as high prices, low costs, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

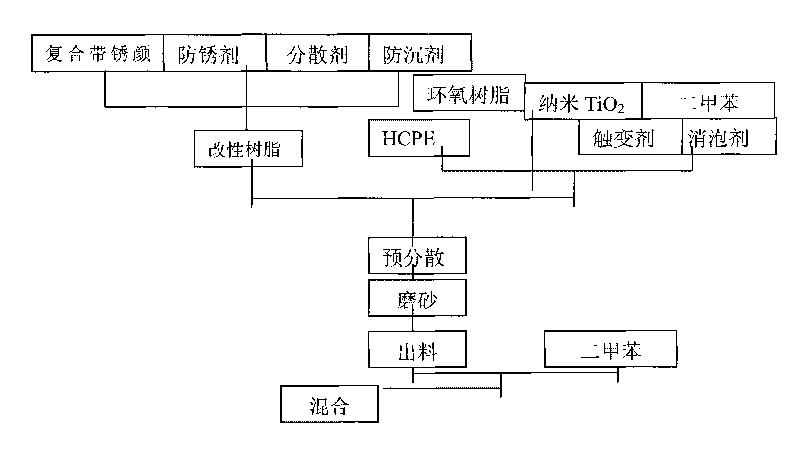

Method used

Image

Examples

Embodiment 1

[0043] Table 4 Example 1 formula

[0044] material name

[0045] material name

[0046] According to Table 4, add zinc molybdate, zinc phosphate and aluminum tripolyphosphate into 210 phenolic resin and C9 petroleum resin with a mass ratio of 2:1, add anti-sedimentation agent and dispersant, and pre-grind in a grinder to achieve fine Degree 50μm. Epoxy resin E51, TiO 2 Pre-grind with xylene according to the ratio, the fineness is 50μm. Mix the two pre-ground materials with high chlorinated polyethylene resin according to the ratio, add defoamer, and grind to a fineness of 30 μm.

[0047] Table 5 Example 1 coating main performance index

[0048] project

[0049] project

[0050] Note: The above test coatings are all applied to the steel structure with a rust layer thickness of 60μm

Embodiment 2

[0052] Table 6 Embodiment 2 formula

[0053] material name

[0054] material name

[0055] Add iron oxide red and zinc oxide into 210 phenolic resin and C9 petroleum resin with a mass ratio of 5:1 according to Table 6, add anti-sedimentation agent, nano-SiO 2 and dispersant, pre-grinded in a grinder to a fineness of 50 μm. Epoxy resin E51, TiO 2 Pre-grind with xylene according to the ratio, the fineness is 50μm. Mix the two pre-grinding materials with high chlorinated polyethylene resin according to the ratio and add defoamer, and grind to a fineness of 30 μm.

[0056] Table 7 embodiment 2 main performance index of coating

[0057] project

[0058] project

[0059] Note: The above test coatings are all applied to the steel structure with a rust layer thickness of 60μm

Embodiment 3

[0061] Table 8 Example 3 formulation

[0062] material name

[0063] material name

[0064] Add zinc molybdate, zinc phosphate and aluminum tripolyphosphate in the 210 phenolic resin and C9 petroleum resin with a mass ratio of 3:1 according to Table 8, add anti-settling agent, nano-SiO 2 and dispersant, pre-grinded in a grinder to a fineness of 50 μm. Epoxy resin E51, TiO 2 Pre-grind with xylene according to the ratio, the fineness is 50μm. Mix the two pre-ground materials with high chlorinated polyethylene resin according to the ratio, add defoamer, and grind to a fineness of 30 μm.

[0065] Table 9 Example 3 coating main performance index

[0066] project

[0067] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com