Preparation method of resin-based composite material sanitary ware hardware

A technology of composite materials and hardware, applied in the field of sanitary ware hardware, to achieve the effect of reducing labor intensity, not easy to accumulate dirt, and easy to scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

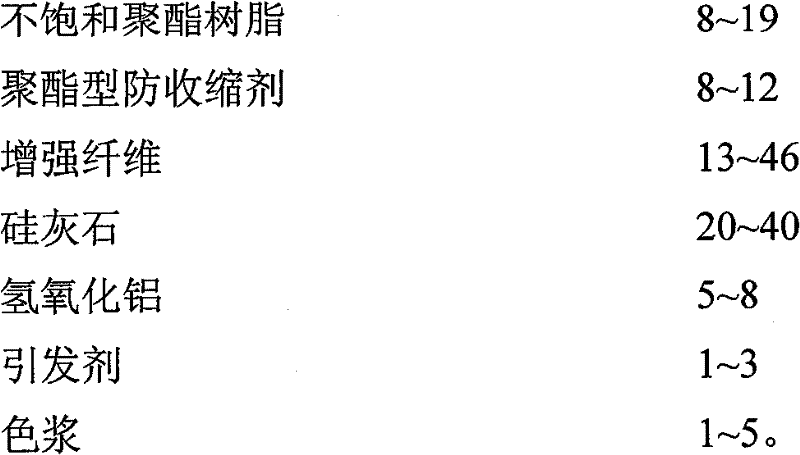

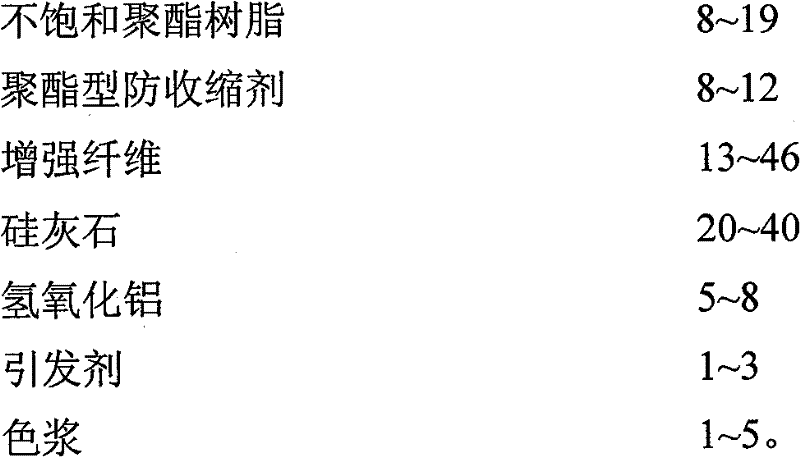

[0064] Embodiment 1, 18 parts of upper latitude 928 unsaturated polyester resins, 12 parts of upper latitude 7310 polyester type anti-shrinkage agents, 8 parts of nylon 66 chopped fibers, 12 parts of polyester chopped fibers, 40 parts of 1250 orders or 600 orders Wollastonite particles, 5 parts of aluminum hydroxide particles, 3 parts of color paste, 2 parts of benzoyl peroxide (BPO) and 1 part of tert-butyl oxybenzoate (TBPB) initiators are fully mixed. The mixture is pre-cured for 12 hours in a temperature environment of 40-50°C, and then pressed into a mold, kept in a temperature environment of 80°C for half an hour, and kept in a temperature environment of 130-140°C for 1 hour. After the pressed product is cooled, it is released from the mold to obtain the product.

[0065] The tensile strength of the cured material can reach 70MPa, and the compressive and bending strengths exceed 100MPa. The surface of the obtained product is smooth, and the pencil hardness reaches 6H. ...

Embodiment 2

[0066] Embodiment 2, 16 parts of upper latitude 928 unsaturated polyester resins, 10 parts of upper latitude 7310 polyester type anti-shrinkage agents, 12 parts of nylon 66 chopped fibers, 15 parts of polyester chopped fibers, 38 parts of 1250 orders or 600 orders of silicon Limestone particles, 5 parts of aluminum hydroxide particles, 2 parts of color paste, 2 parts of benzoyl peroxide (BPO) and 1 part of tert-butyl oxybenzoate (TBPB) initiator are fully mixed. The mixture is pre-cured at a temperature of 40-50°C for 12 hours, and then injected into a mold at a temperature of 150-180°C. After the product is cooled, it is post-cured at 150°C for 1 hour, and the finished product is demoulded.

[0067] The tensile strength of the cured material can reach 70MPa, and the compressive and bending strengths exceed 100MPa. The surface of the obtained product is smooth, and the pencil hardness reaches 6H. Tested by Shanghai Institute of Quality Supervision, Inspection and Technology, ...

Embodiment 3

[0068] Embodiment 3, 17 parts of upper latitude 928 unsaturated polyester resins, 11 parts of upper latitude 7310 polyester type anti-shrinkage agents, 7 parts of nylon 66 chopped fibers, 12 parts of 6 mm glass fibers, 39 parts of 1250 orders or 600 orders of silicon Limestone particles, 6 parts of aluminum hydroxide particles, 4 parts of color paste, 2 parts of benzoyl peroxide (BPO) and 1 part of tert-butyl oxybenzoate (TBPB) initiator are fully mixed. The mixture is pre-cured for 12 hours at a temperature of 40-50°C, and then injected into a mold at a temperature of 150-180°C. After the product is cooled, it is post-cured at 150°C for 1 hour, and the finished product is obtained after demoulding.

[0069] The surface of the obtained product is smooth, showing a marble-like pattern, and the pencil hardness reaches 5H and 6H. Tested by Shanghai Institute of Quality Supervision, Inspection and Technology, the product was soaked in water at 60°C for 2 hours, and the test result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com