Complete biodegradation foam material and preparation method thereof

A foaming material and biodegradable technology, applied in the field of foaming materials, can solve the problems of unsatisfactory physical properties and manufacturing costs, low strength and fracture performance of foamed products, and inability to completely degrade foamed materials, etc. Hydrophilic, accelerated degradation rate, high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

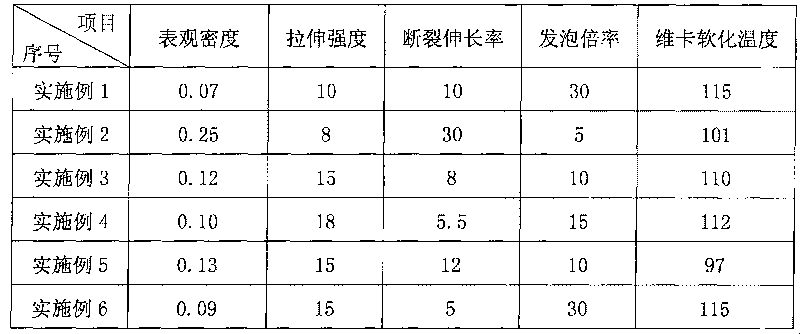

Examples

Embodiment 1

[0023] The foaming material of this embodiment is prepared from 60kg of polyhydroxybutyrate, 40kg of cornstarch and 3.5kg of AC composite foaming agent.

[0024] Preparation method: dehumidify the corn starch in a high-speed mixer, the moisture content of the corn starch is between 0-1%, dry the polyhydroxybutyrate and AC composite foaming agent in an electric blast drying oven, and the drying temperature is The temperature is 80°C, and the drying time is 6 hours; weigh all the components of the corresponding weight, add them to a high-speed mixer and stir at high speed for 5 minutes; put the mixed materials into a twin-screw extruder to melt and plasticize, and complete the blending. The mixing temperature is 120°C; all kinds of foamed products are formed by special auxiliary molding heads such as T-shaped.

Embodiment 2

[0026] The weight of each component of the foam material of this embodiment is 40 kg of P3HB4HB (4HB molar content is 90%), 60 kg of potato starch, 1 kg of AC foaming agent, and 0.5 kg of foaming accelerator ZnO.

[0027]Preparation method: dehumidify potato starch in a high-speed mixer, and the moisture content of potato starch is between 0-1%; dry P3HB4HB, AC foaming agent, and foaming accelerator ZnO in an electric blast drying oven, and the drying temperature The temperature is 100°C, and the drying time is 2 hours; weigh all the components of the corresponding weight, add them to a high-speed mixer and stir at high speed for 10 minutes; put the mixed materials into a twin-screw extruder to melt and plasticize, and complete the blending. The mixing temperature is 150°C; after being granulated by a twin-screw extruder, it is foamed into products of various shapes in a heated mold, and the mold heating temperature is 120°C.

Embodiment 3

[0029] The weight of each component of the foaming material of the present embodiment is respectively P3HB4HB (4HB molar content is 10%) 80kg, tapioca starch powder 20kg, AC composite foaming agent 1.5kg, ZnO 0.3kg, stearic acid 0.8kg, four [ 0.5 kg of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, 5 kg of talc, and 1 kg of glycerin.

[0030] Preparation method: dehumidify tapioca starch in a high-speed mixer, and the moisture content of tapioca starch is between 0-1%; mix P3HB4HB, AC composite foaming agent, ZnO, stearic acid, tetrakis [β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, talcum powder, and glycerin are dried in an electric blast drying oven at a drying temperature of 60°C and a drying time of 9 hours; weigh all components of the corresponding weight , put into the high-speed mixer and stir at high speed for 10 minutes; put the mixed material into the twin-screw extruder to melt and plasticize, and complete the blendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com