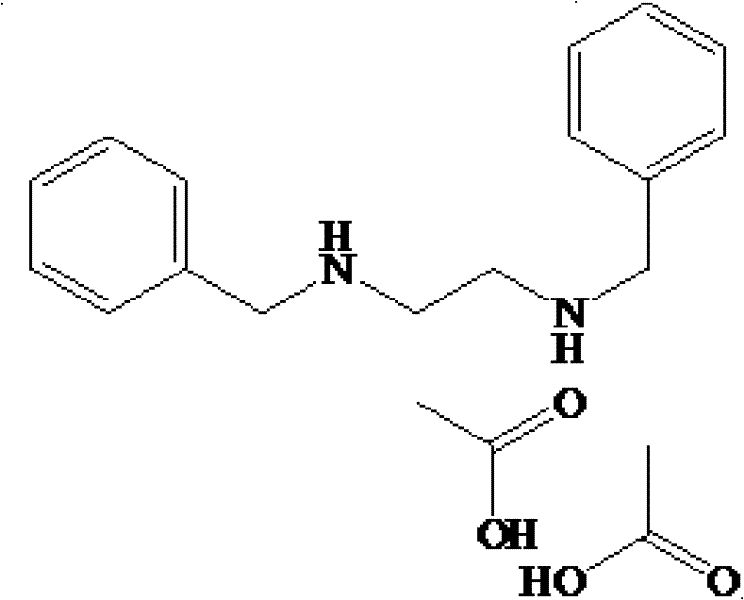

Preparation method of N,N-dibenzyl-ethylenediamin diacetate

A technology of dibenzylethylenediamine and dibenzylideneethylenediamine, which is applied in the N field, can solve the problems of low product yield, easy pollution of the environment, and high impurity content, and achieve high product yield, broad market prospects, The effect of low product impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

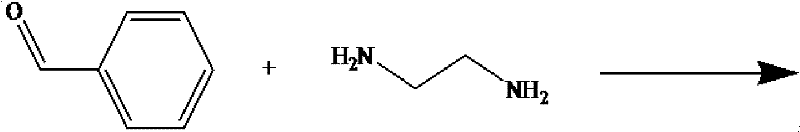

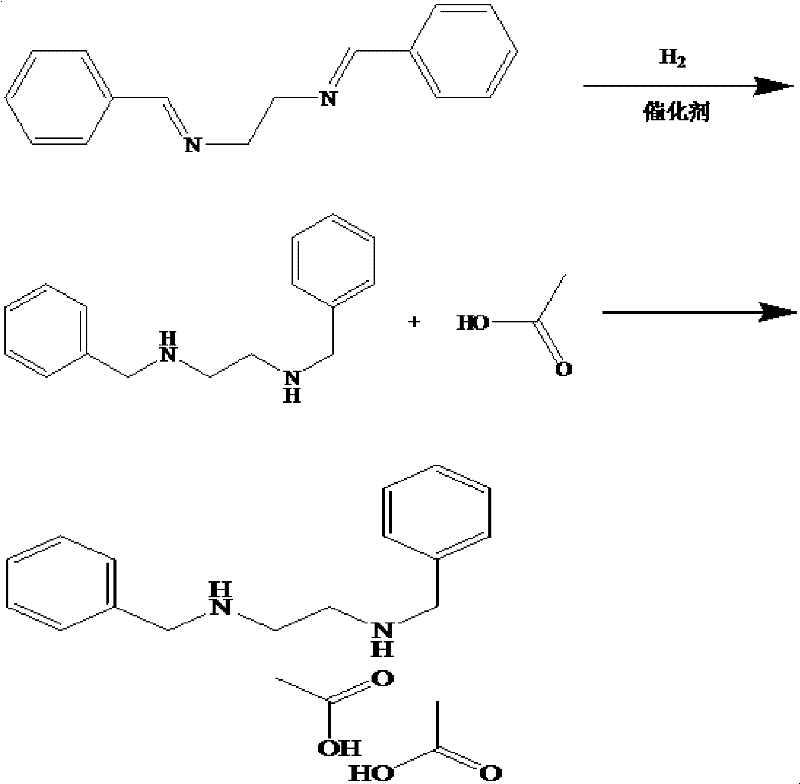

Method used

Image

Examples

Embodiment 1

[0023] Put 700kg of benzaldehyde and 200kg of ethylenediamine into a 2000L reactor, stir, react at a temperature of 120°C for 4 hours, cool, measure the solid weight to 786.0kg, put the resulting solid into a 5000L autoclave, add 2000kg of ethyl acetate, add 0.8kg catalyst Pd / c, hydrogenation reaction at a pressure of 0.5MPA and a temperature of 100°C for 4 hours, the solution was cooled, filtered, transferred to a 5000L reactor, added 400kg of glacial acetic acid, stirred and reacted at 80°C for 4 hours , cooled, stirred at 5° C. for 1 hour, filtered with suction, and dried to obtain 1105.6 kg of product with a yield of 93%.

Embodiment 2

[0025] Add 700g of benzaldehyde, 200g of ethylenediamine, and 1000g of ethyl acetate into a 3000ml three-necked flask, stir it magnetically, and react at a temperature of 80°C for 4 hours, then transfer the solution into a 5000ml autoclave, add 0.8g of catalyst Pd / c, and The pressure is 0.5MPA, the temperature is 100°C and hydrogenation reaction is carried out for 4 hours, the solution is cooled, filtered, transferred to a 5000ml three-necked flask, 1000g of ethyl acetate and 400g of glacial acetic acid are added, stirred and reacted at 80°C for 4 hours, cooled, Stir at 5° C. for 1 hour, and dry to obtain 1129.3 g of the product, with a yield of 95%.

Embodiment 3

[0027] Add 700g of benzaldehyde, 200g of ethylenediamine, and 1000g of ethyl acetate into a 3000ml three-necked flask, stir magnetically, react at a temperature of 80°C for 4 hours, then transfer the solution to a 5000ml autoclave, add 0.8g of catalyst Ni, 0.6MPA, hydrogenation reaction at 100°C for 4 hours, the solution was cooled, filtered, transferred to a 5000ml three-necked flask, added 1000g ethyl acetate, 400g glacial acetic acid, stirred and reacted at 80°C for 4 hours, cooled, at 5°C Stir for 1 hour, filter with suction, and dry to obtain 1099.6 g of the product, with a yield of 92.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com