Full-automatic efficient integrated brick and stone facing protection method and device thereof

A protective device, fully automatic technology, used in the field of building materials to achieve the effect of improving corrosion resistance and surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

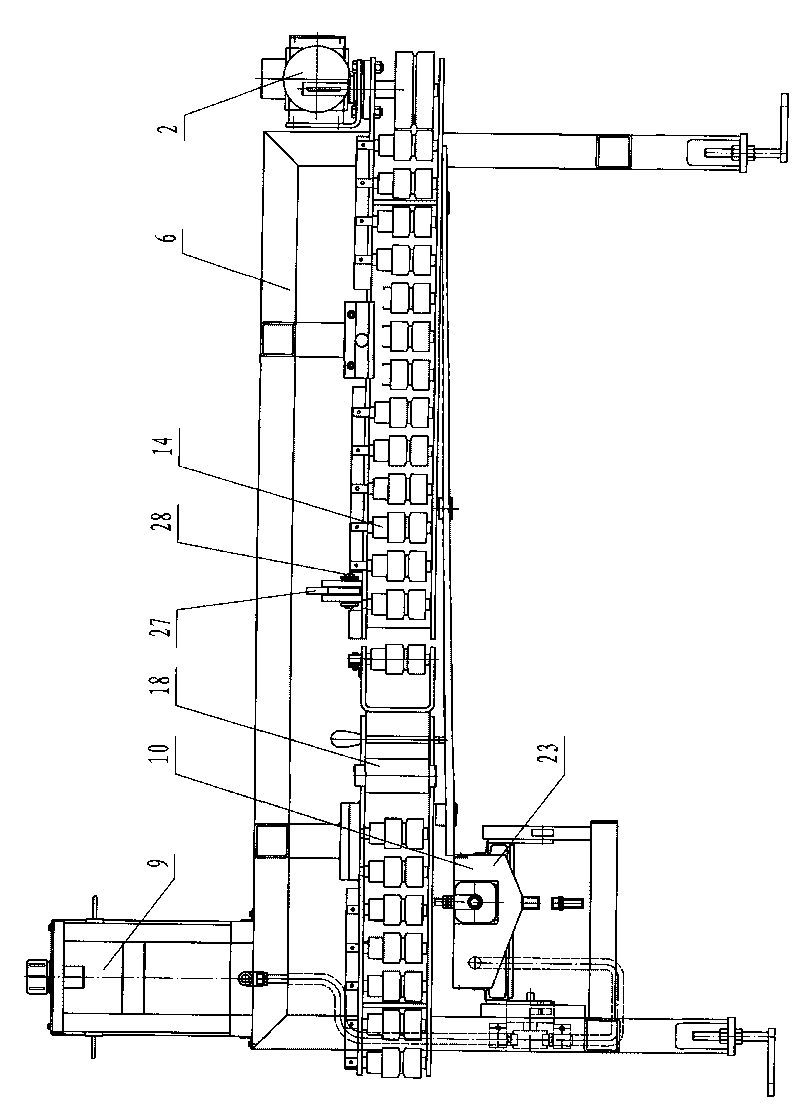

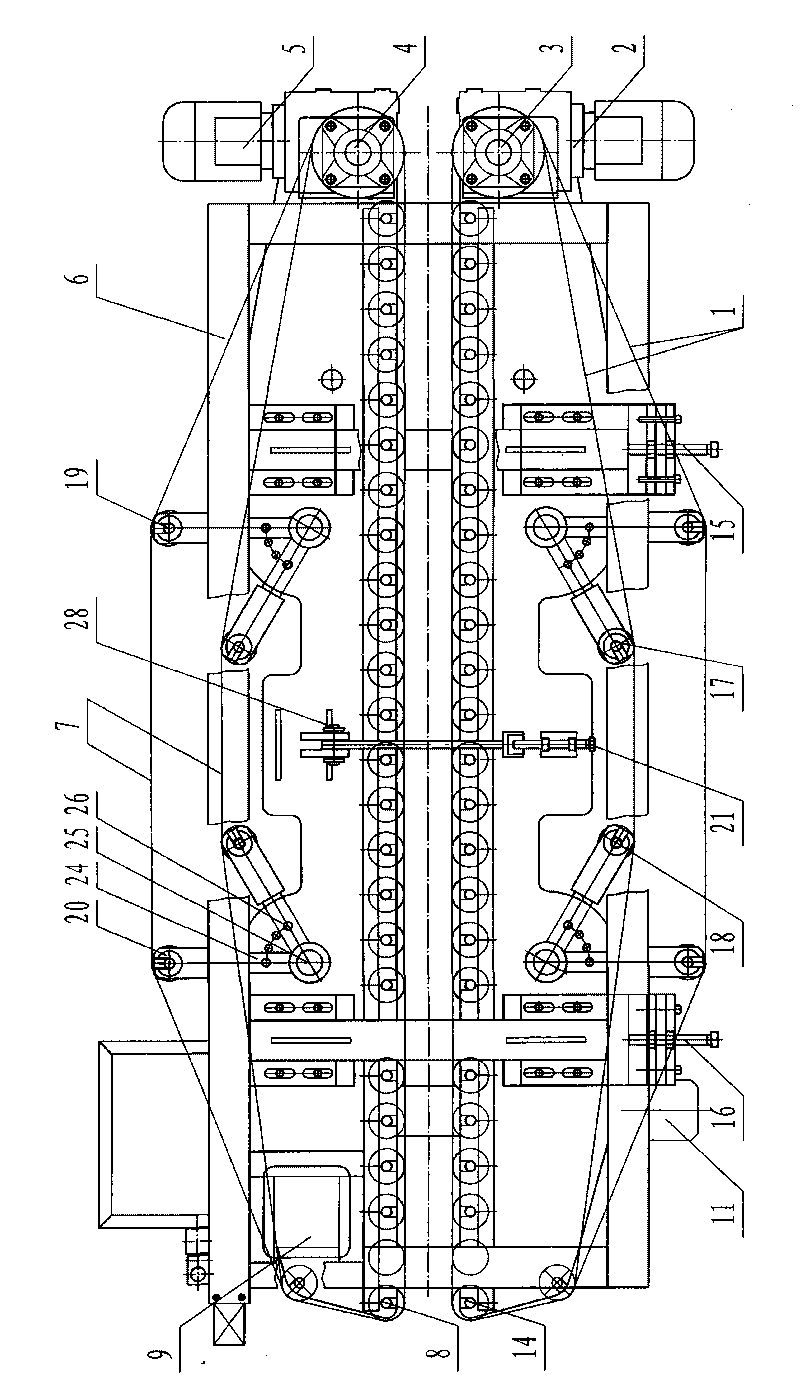

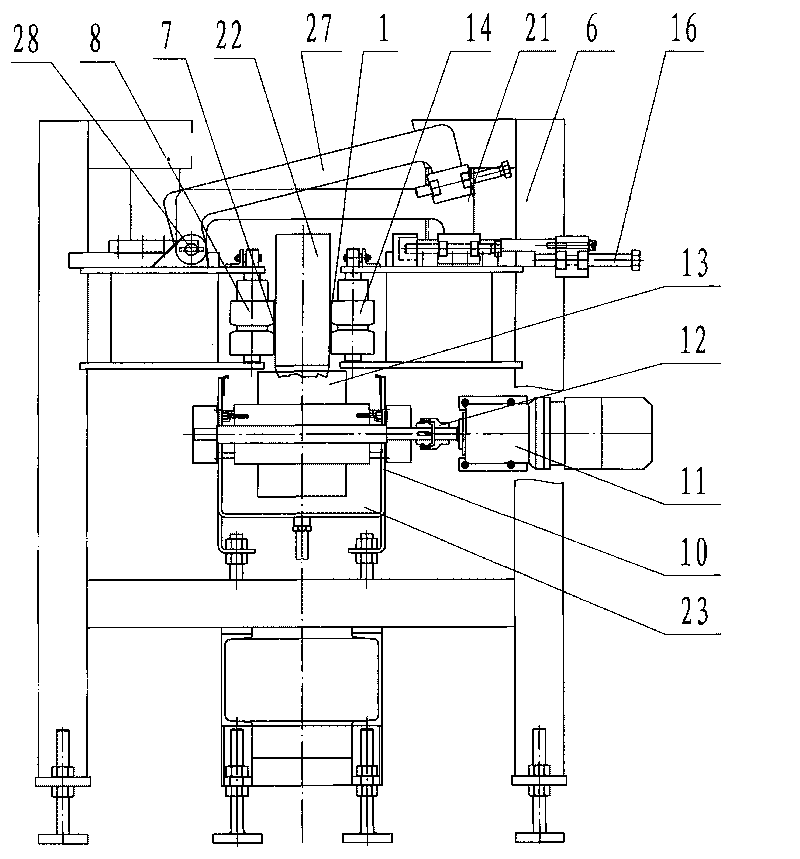

[0017] With reference to the drawings, specific embodiments of the present invention will be described.

[0018] Such as figure 1 Shown: the fully automatic and efficient integrated brick and stone facing protection method of the present invention: the processed brick and stone facing down are fed into the middle of two vertical, relatively parallel, separately driven side conveyor belts, two A conveyor belt clamps the two sides of the brick and conveys it forward. During the conveying process of the brick and stone, the impregnating liquid is applied to the surface of the brick and stone veneer by the brush set under the two conveyor belts. Under the conveyance of the side conveyor belt, it enters the next processing procedure.

[0019] As attached figure 1 , 2 3. Shown in 3: The fully automatic and efficient integrated brick and stone veneer protection of the present invention includes two sets of vertical side belt conveyors, a set of rolling brushing device, frame 6, electric c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com