Power coupler of hybrid vehicle

A hybrid vehicle and power coupler technology, which is applied to the arrangement of multiple different prime movers of hybrid vehicles, general power plants, motor vehicles, etc., can solve the problems of poor versatility and reliability, difficult matching requirements, and inability to form Industrialization and other issues, to achieve the effect of fast switching and easy matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The invention is explained in more detail below with reference to preferred embodiments.

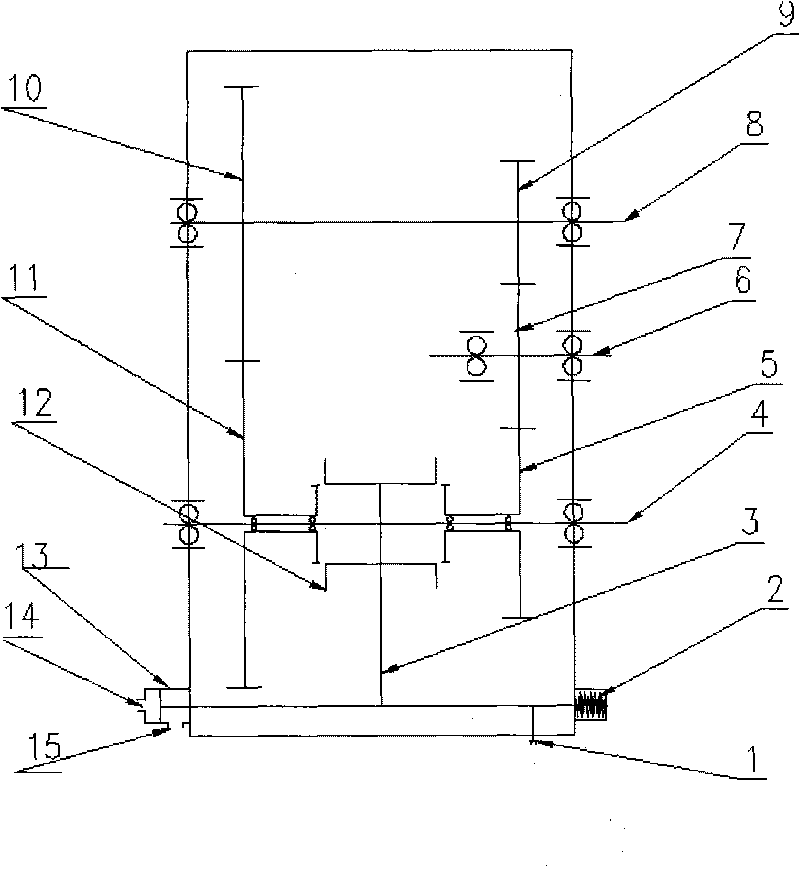

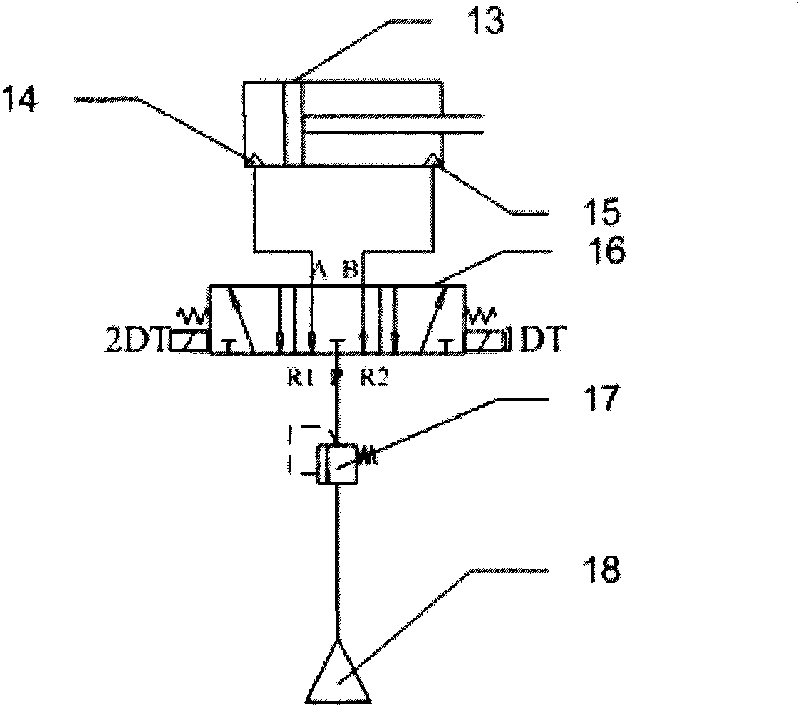

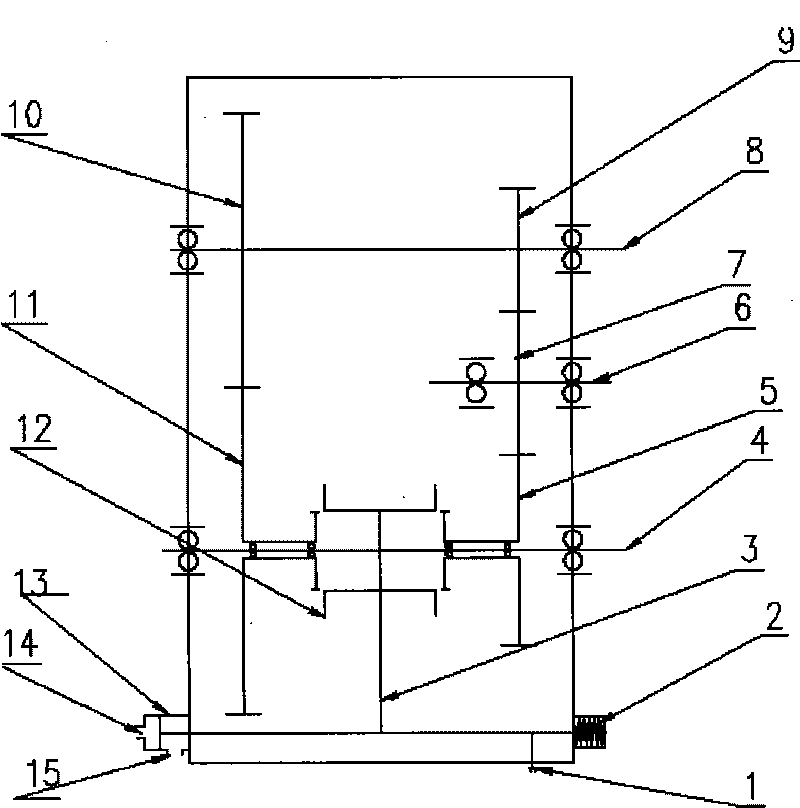

[0047] See figure 1 , the dynamic force coupler of the hybrid vehicle of the present invention includes a gear position feedback signal interface 1, a cylinder return spring group 2, a shift fork 3, a power coupling shaft 4, a power element connecting shaft with the same direction gear 5, and a reversing center Shaft 6, same-direction intermediate gear 7, power element connecting shaft 8, power coupling shaft co-direction gear 9, power coupling shaft reverse gear 10, power element coupling shaft reverse gear 11, bidirectional synchronizer 12, double-acting cylinder 13 and The electronic control operation module is composed. The gear position feedback signal interface 1 is set on the shell of the power coupler, the cylinder return spring group 2 is set on the outside of the double-acting cylinder 13, the power coupling shaft co-directional gear 9 and the power coupling shaft rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com