Method for removing various gaseous pollutants from smoke gas

A pollutant and flue gas technology, applied in the field of flue gas purification, can solve the problems of low absorption capacity, large MEA loss, high cost, etc., and achieve the effect of low removal cost, high mercury removal performance, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

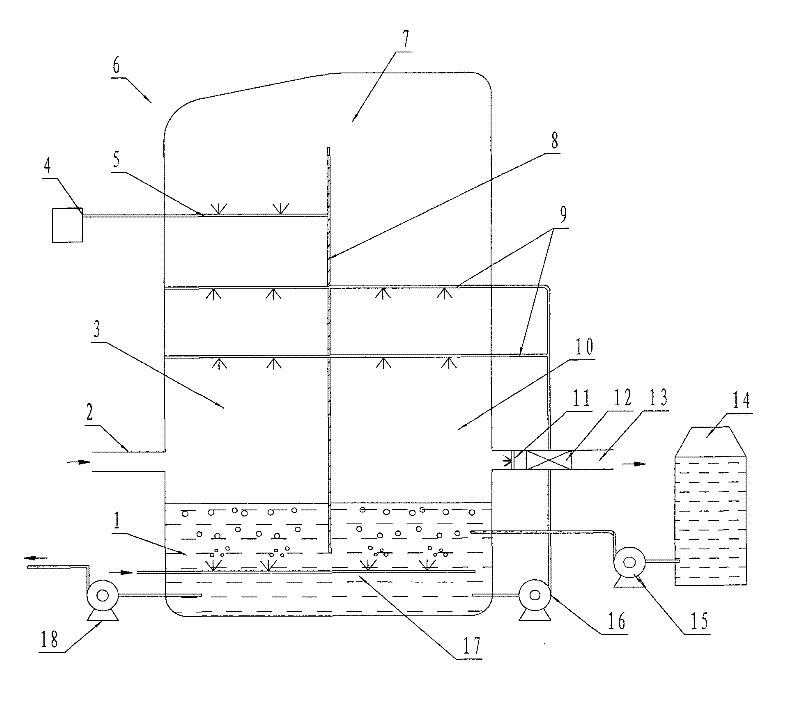

[0018] Embodiment 1: see figure 1 The bottom of the absorption tower 6 is provided with an absorption slurry pool 1; the middle part is provided with a spray pipe 9, and the spray pipe is connected to the absorption liquid pool by an absorption liquid circulation pump 16 and pipelines, and the pH value of the absorption liquid in the absorption slurry pool is maintained at 5 to 7. The absorption liquid is ammonia water; the upper part of the absorption tower is provided with an oxidant pipe 5, the oxidant is ozone, and the ozone is added to the oxidation zone 7 in the gas phase, because most of the SO 2 It is removed in the desulfurization section 3, reducing the SO 2 The amount of ozone consumed by oxidation, thereby reducing the consumption of ozone by the system, the oxidant pipe is connected to the ozone generator 4, and the added ozone and the NO in the flue gas X Molar ratio (O 3 / NO) is controlled within the range of 0.5 to 2.0, in this embodiment NO X molar ratio O ...

Embodiment 2

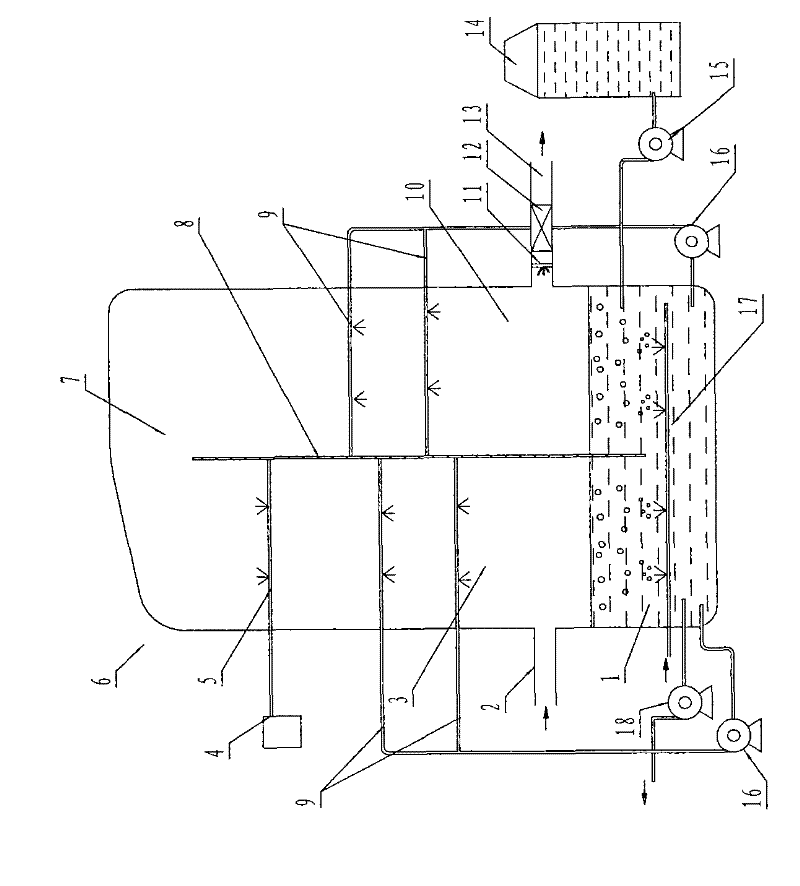

[0045] Embodiment 2: see figure 2 , the 90-120°C flue gas enters the desulfurization section 3 from the absorption tower inlet 2, and the SO 2 In the removal of HCl and HCl, the flue gas in the desulfurization working section flows upwards, and after contacting and reacting with the absorption liquid (ammonia water) sprayed from the spray pipe 9, the temperature drops to 50-100°C, and the SO 2 and HCl removal; the flue gas continues upward into the oxidation zone, where NO in the flue gas is oxidized to a higher oxidation state of NO by the ozone ejected from the oxidizer pipe X , while elemental mercury is oxidized to divalent mercury, NO in this example X molar ratio O 3 / NO is 1.0; the flue gas continues to descend into the denitrification and decarbonization working section 10, and the highly oxidized NO in the flue gas in this working section X , divalent mercury and CO 2 React with the spray pipe 9 to spray the absorption liquid to complete the NO X , mercury vapor...

Embodiment 3

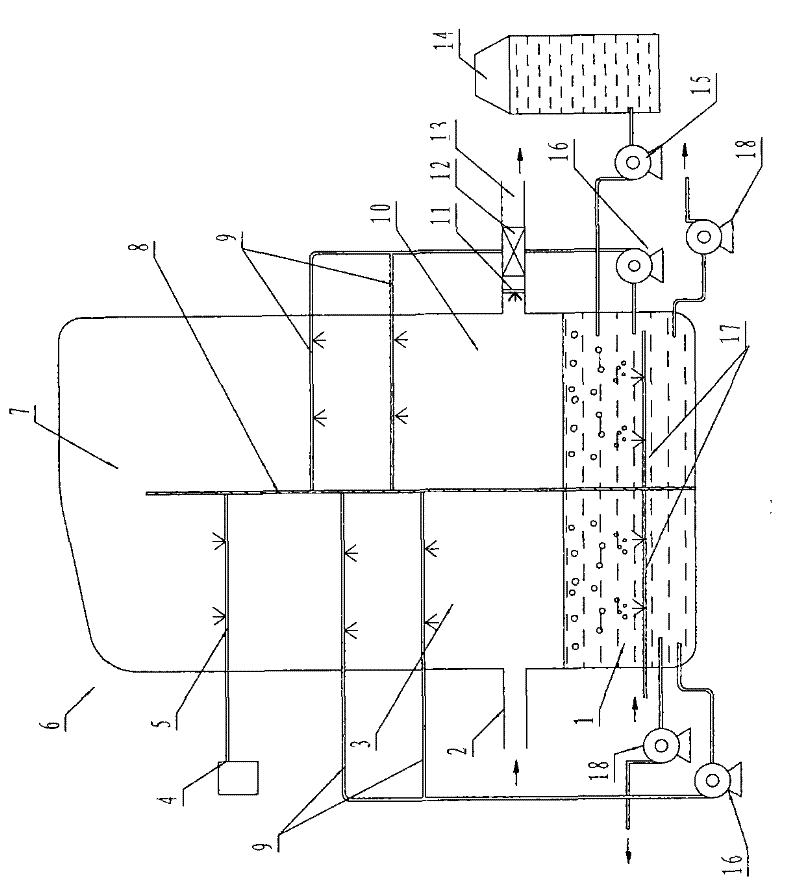

[0046] Embodiment 3, see image 3 , the 90-120°C flue gas enters the desulfurization section 3 from the absorption tower inlet 2, and the SO 2 In the removal of HCl, the flue gas in the desulfurization working section flows upwards, and after contacting and reacting with the absorption liquid sprayed by the spray pipe 9, the temperature drops to 50-100°C, and the SO 2 and the removal of hydrogen chloride; the flue gas continues upward into the oxidation zone 7, where NO in the flue gas is oxidized by ozone to a higher oxidation state of NO X , while elemental mercury is oxidized to divalent mercury, NO in this example X molar ratio O 3 / NO is 2.0; the flue gas continues to descend into the denitrification and decarbonization working section 10, and the highly oxidized NO in the flue gas in this working section X , divalent mercury and CO 2 React with the spray pipe 9 to spray the absorption liquid to complete the NO X , mercury vapor and CO 2 remove. The clean flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com