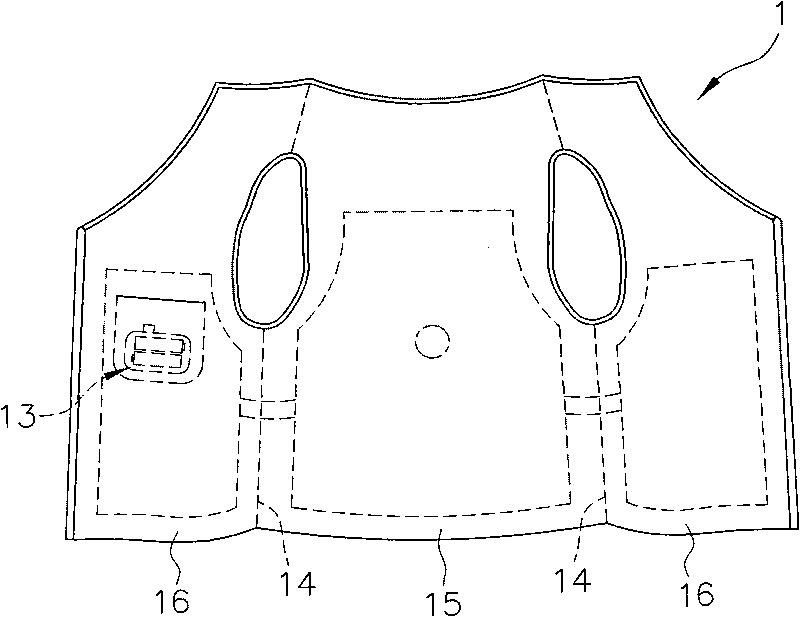

Stitching-free heat-preserving clothes and production method thereof

A production method and a seamless thread technology, which are applied in the field of clothing and its production, can solve the problems of discounting the thermal insulation effect, affecting the thermal insulation and moisture resistance of clothing 1, and the inability to continue to exert heat and warmth, and achieve the effect of fine and dense texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Before describing the present invention in detail, it is noted that in the following description, similar components are denoted by the same numerals.

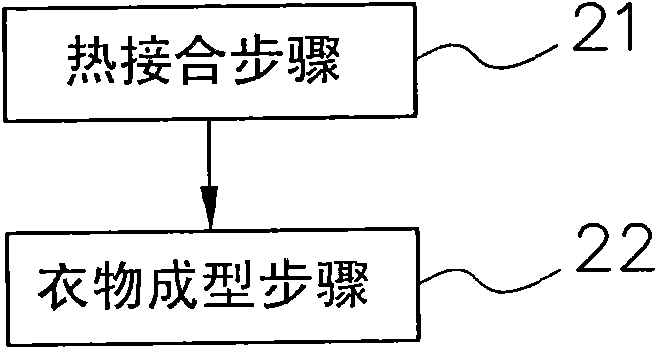

[0028] refer to image 3 , the first preferred embodiment of the production method of the seamless thermal insulation clothing of the present invention, which includes a thermal bonding step 21 and a clothing forming step 22, wherein the thermal bonding step 21 is made of thermoplastic polyurethane raw material (hereinafter referred to as TPU) The first layer 31 of the foam type made is bonded to the second layer 32 of the film type made of TPU raw material in a heating mode, to form a thermal insulation clothing material 30 (such as Figure 4 shown).

[0029] Generally speaking, the main difference between the foam type and the film type in the production method is that the foam is to stir the basic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com