High humidity grain dryer

A grain dryer and drying machine technology, applied in the direction of drying and preserving seeds, food processing, climate change adaptation, etc., can solve the problems of large heat loss in the drying medium, cannot meet the moisture content, affect the quality of grain, etc., and achieve the improvement of drying efficiency , Drying and energy-saving effects are obvious, and the effect of reducing the number of configurations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

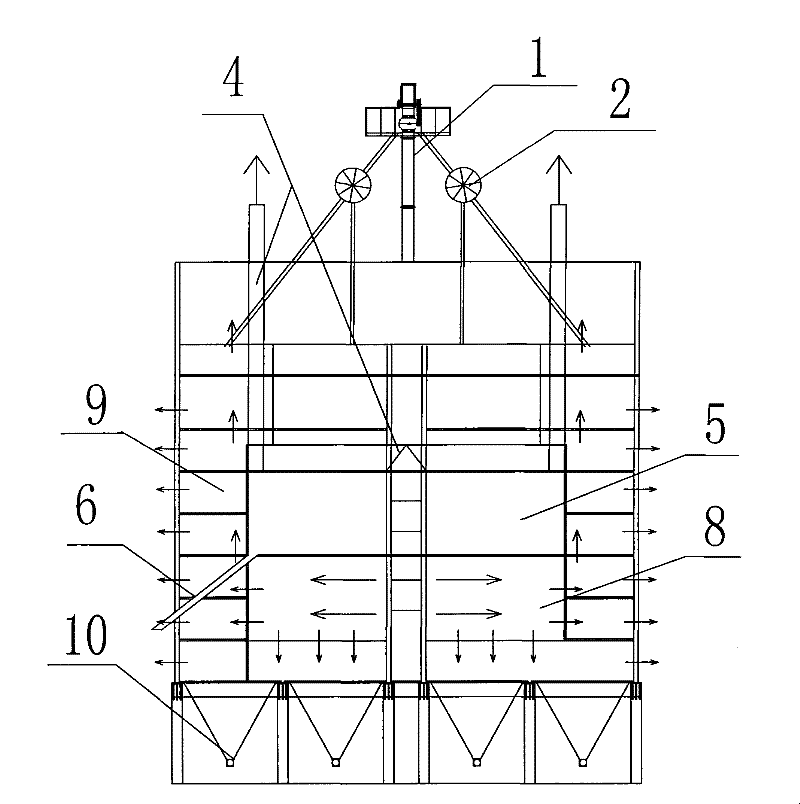

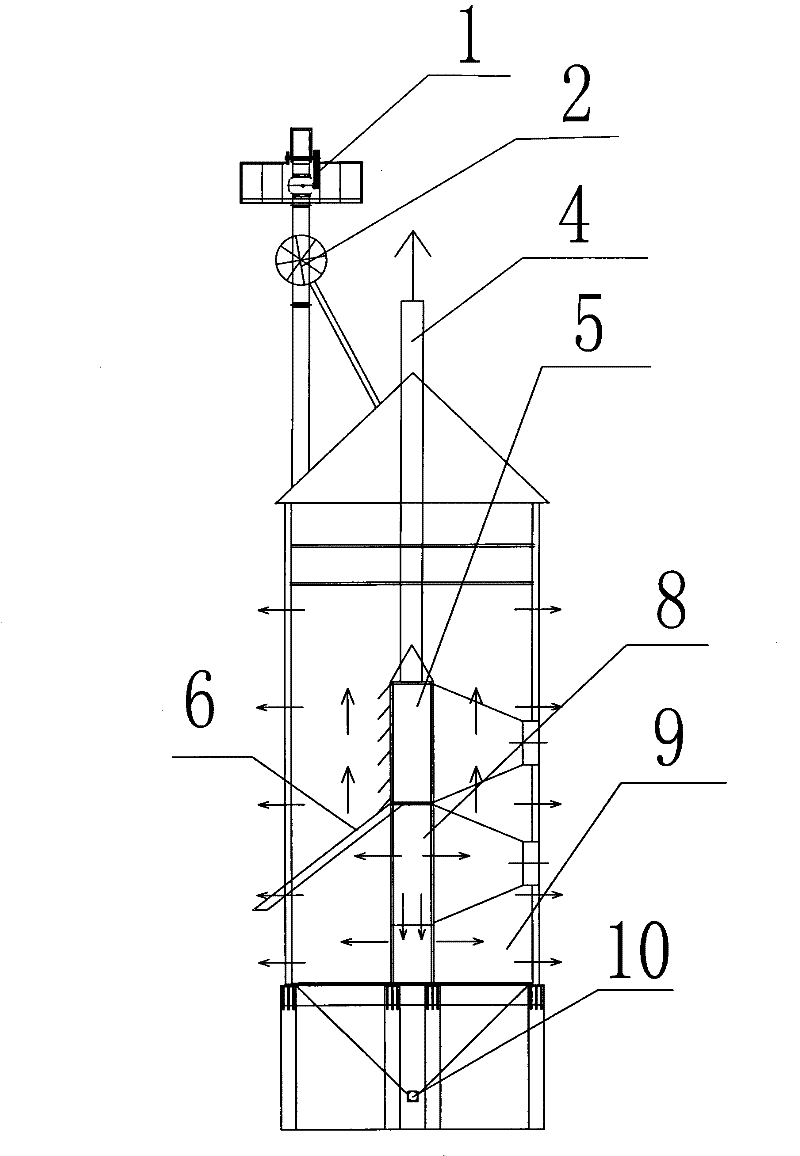

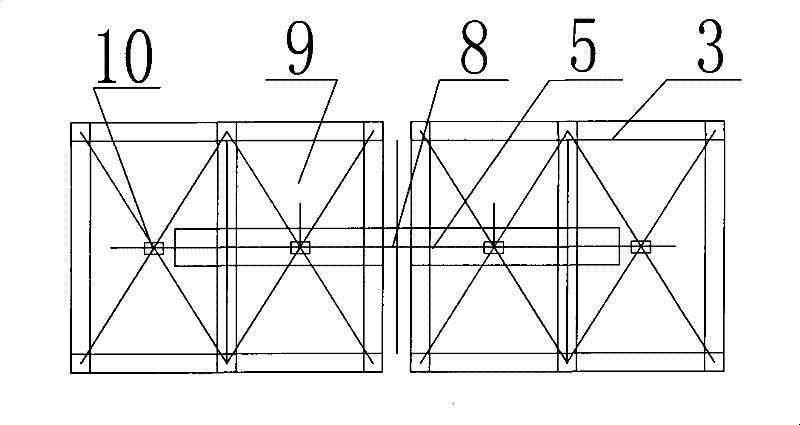

[0031] A high-humidity grain dryer in this embodiment has a structure such as figure 2As shown, a high-humidity grain dryer is provided with a plurality of drying bins 9 capable of simultaneously drying a variety of grains in the dryer body, and the plurality of drying bins 9 are arranged side by side, and each drying bin 9 is surrounded by mesh A ventilation plate, a plurality of drying bins 9 in the dryer body share a heat recovery chamber 5 and an air duct 8, the heat recovery chamber 5 is arranged in parallel above the air duct 8, the bottom surface of the air duct 8 is open and directly connected to each drying bin body 9 are connected; the heat recovery chamber 5 is externally connected to the flue gas induced draft fan and the hot blast stove through the flue gas channel 4, and the air channel 8 is externally connected to the cooling fan.

[0032] In the above-mentioned high-humidity grain dryer, the upper part of each drying bin 9 is connected to the atmosphere, the b...

Embodiment 2

[0038] The high-humidity grain dryer of this embodiment is applied to large-scale grain centralized drying facilities, such as Figure 4 As shown, according to the direction of grain transportation, the system includes a primary cleaner 13, a wet grain hoist 1, a high-humidity grain dryer 3, a drying tower 14 and a dry grain temporary storage tower 22 arranged in sequence; the high-humidity grain dryer 3 and drying A hot blast stove 15 is arranged between the towers 14, and a hot blast stove 15 is provided with a hot air blower 18 at the top of the hot blast stove 15, and the hot blast is led to the drying tower 14 by the hot blast stove 18, and a heat exchanger 16 is arranged between the hot blast stove 15 and the drying tower 14 to exchange heat. A flue gas induced draft fan 17 is arranged above the device 16, and the flue gas is led to the high-humidity grain dryer 3 through the flue gas induced draft fan 17 and the flue gas duct 4. The inlet ends are connected and an air c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com