Method for compounding fumigant and compound fumigant

A fumigant and the same technology are applied in the compound method and the field of fumigant compounded by sulfuryl fluoride and chlorine gas, which can solve the problem of strong corrosiveness of chlorine gas, reduce the corrosiveness and improve the sterilization effect. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Vacuumize the steel cylinder, and then weigh the steel cylinder with an electronic scale; connect the air inlet of the vacuumized steel cylinder with the gas outlet of the sulfuryl fluoride cylinder, and use the vacuum degree of the steel cylinder to inhale the sulfuryl fluoride gas into the steel cylinder, weigh the steel cylinder again with an electronic scale, the weight difference between the two times is the quality of sulfuryl fluoride in the steel cylinder; connect the air inlet of the steel cylinder containing sulfuryl fluoride with the gas outlet of the chlorine cylinder, According to the remaining vacuum in the steel cylinder and the pressure of the chlorine gas cylinder, a certain amount of chlorine gas is pressed into the steel cylinder, and weighed with an electronic scale to obtain a compound fumigant of sulfuryl fluoride and chlorine gas to ensure the mass ratio of sulfuryl fluoride and chlorine gas 85%: 15%.

Embodiment 2

[0018] Vacuumize the steel cylinder, and then weigh the steel cylinder with an electronic scale; connect the air inlet of the vacuumized steel cylinder with the gas outlet of the sulfuryl fluoride cylinder, and use the vacuum degree of the steel cylinder to inhale the sulfuryl fluoride gas into the steel cylinder, weigh the steel cylinder again with an electronic scale, the weight difference between the two times is the quality of sulfuryl fluoride in the steel cylinder; connect the air inlet of the steel cylinder containing sulfuryl fluoride with the gas outlet of the chlorine cylinder, For the remaining vacuum in the steel cylinder and the pressure of the chlorine gas cylinder, a certain amount of chlorine gas is pressed into the steel cylinder, weighed with an electronic scale, and the compound fumigant of sulfuryl fluoride and chlorine gas is obtained. The mass ratio of sulfuryl fluoride and chlorine gas is 95%: 5%.

Embodiment 3

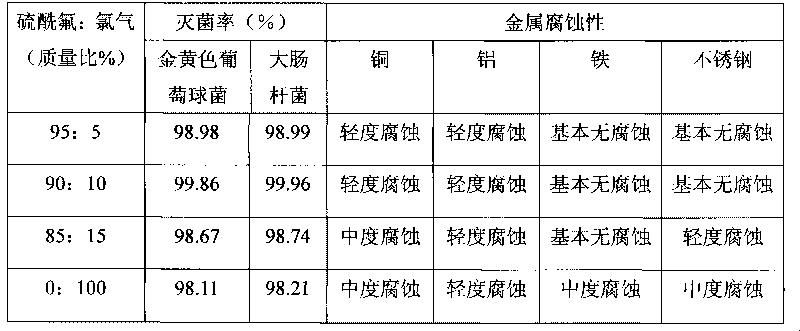

[0020] The composite fumigant containing sulfuryl fluoride and chlorine obtained by the method of Example 1 was used to carry out the sterilization experiment.

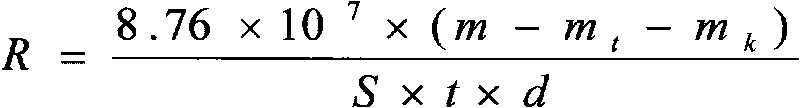

[0021] The 3rd generation Escherichia coli 8099 and Staphylococcus aureus were respectively inoculated on the agar slant, cultured at 37°C for 24 hours, washed with 5.0ml sterile normal saline diluent, and transferred to a sterile test tube. After fully shaking, make a bacterial suspension and store it in a 4°C refrigerator for later use. Perform viable culture counts before use. After counting, the bacterial suspension was diluted to about 10 7 cfu / ml. Spread the sterilized carrier sheets flat on a sterile plate, and add the bacterial suspension drop by sheet, the amount of each drop is 20 μl. Use a 20 μl pipette to connect a sterilized plastic tip to drip the bacterial solution, and use an inoculation loop to spread the entire surface of the carrier evenly. After the bacterial suspension is dripped, put the carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com