Automatic test control system and method in production of POS machine

An automatic testing and control system technology, applied in the complete banking system, complete banking system, measuring electricity, etc., can solve the problems of slow testing speed, affecting production efficiency and product quality, and high rate of human misjudgment, so as to improve production Efficiency, fast test speed, and low human error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

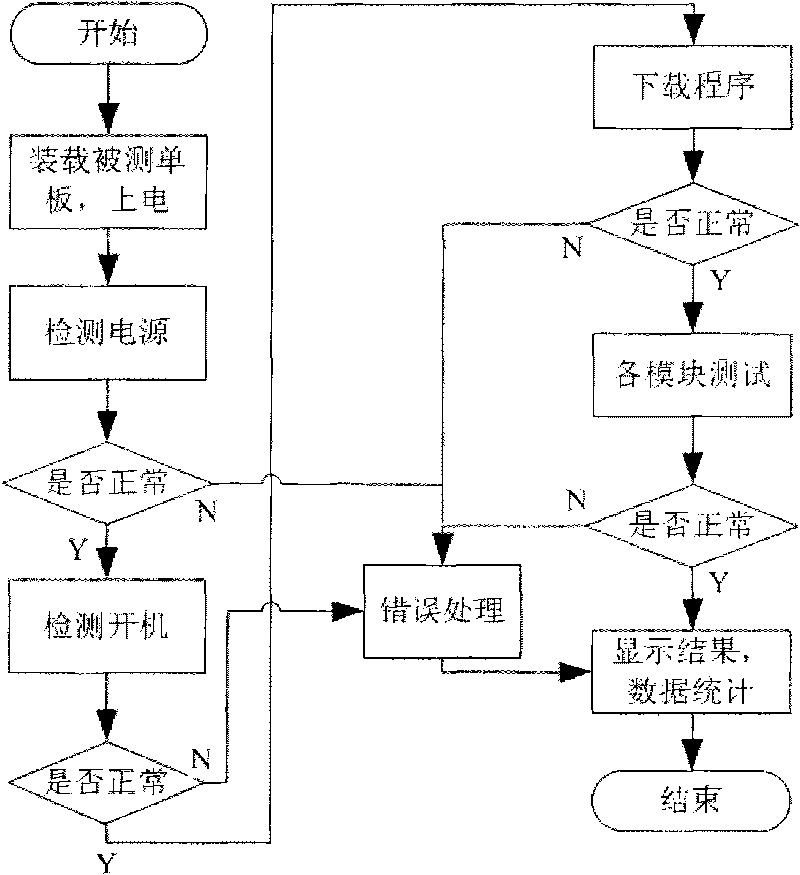

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

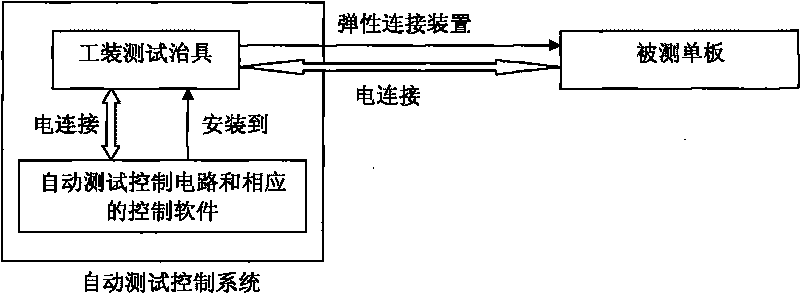

[0027] Such as figure 1 As shown, the automatic test control system of the present invention is composed of a tooling test fixture, an automatic test control circuit and corresponding control software. The automatic test control circuit board is installed on the tooling test fixture, and the tooling test fixture is connected to the single board under test through an elastic connection device; Test single board and automatic test control circuit power supply.

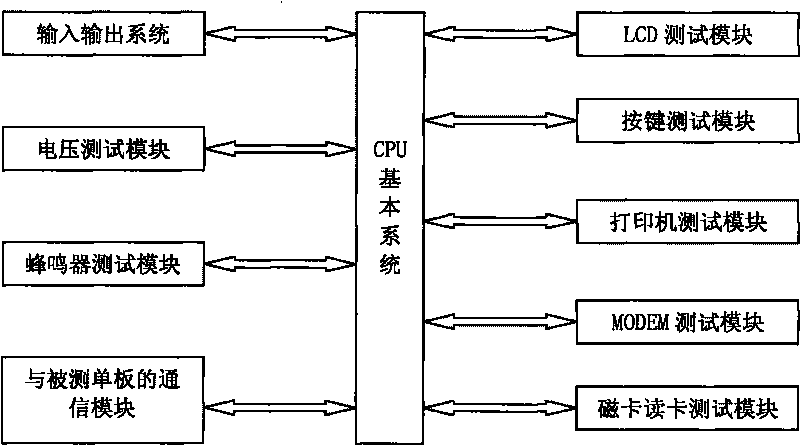

[0028] Such as figure 2 As shown, the automatic test control circuit of the present invention comprises: CPU basic system and the input output system electrically connected with CPU basic system, voltage test module, buzzer test module, magnetic card reading test module, LCD test module, button test module , a printer test module, a MODEM test module, and a communication module with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com