Normal-pressure horizontal fixed fire grate gasification layer firing boiler

A horizontal and atmospheric technology, which is applied to the grate of hollow bars, combustion of solid fuel, grate, etc., can solve the problems of air pollution and low combustion efficiency, and achieve full combustion, high safety performance and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

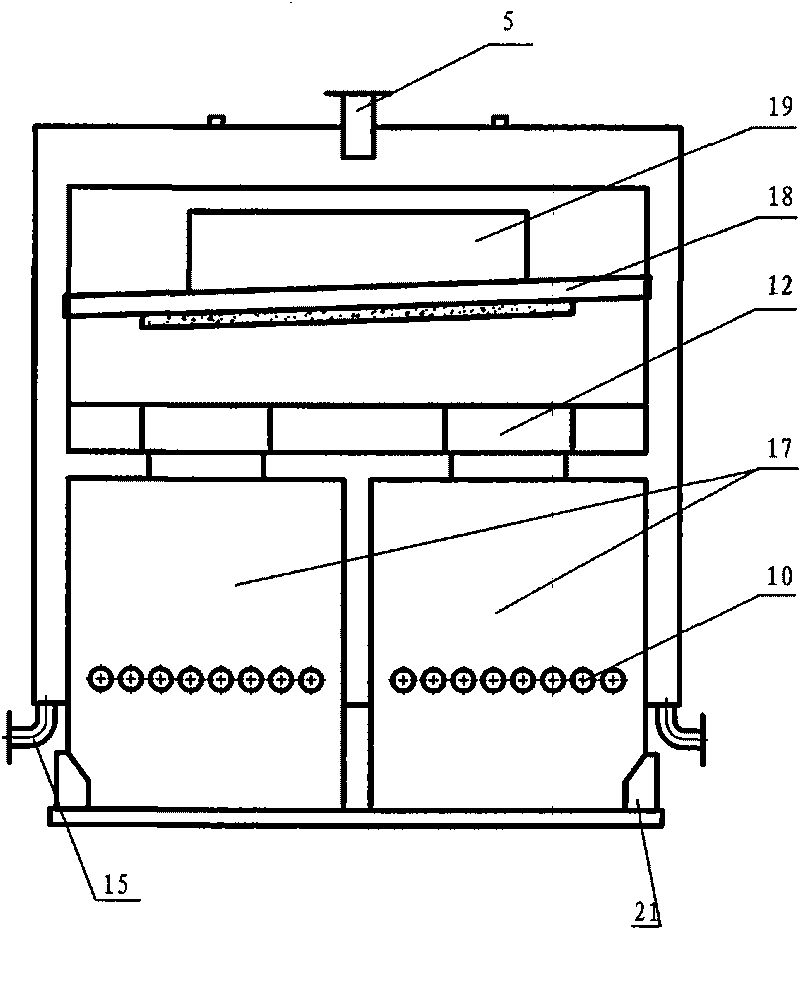

[0021] Atmospheric pressure horizontal fixed furnace degassing layer-fired boiler, including furnace body 7, fire grate 10, throat 12, furnace rear body 3, furnace gall 6, combustion chamber 17, and air distribution chamber 21;

[0022] The top of the body of furnace 7 is a flat top plate 2, the front, back and both sides of the body of furnace 7 are vertical surfaces, and the body of furnace 7 is a horizontal square structure;

[0023] The bottom of the furnace body 7 is provided with two bases 16 side by side. An air distribution chamber 21 is respectively arranged on the outside of the base and is connected to the two bases 16 respectively. The air distribution chamber 21 is rectangular, and one end of the air distribution chamber 21 is provided with a vent , the air vent is externally connected to the fan, and the upper end of the air distribution chamber 21 is provided with an air outlet; a space is provided between the two bases 16, and two fixed fire grates composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com