Release packer capable of well-flushing

A packer and well flushing technology, applied in the directions of sealing/packing, cleaning equipment, wellbore/well components, etc., can solve the problems of the packer being unable to be seated, the construction success rate is low, and it cannot be completed, etc., to achieve reliable Seat seal, the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

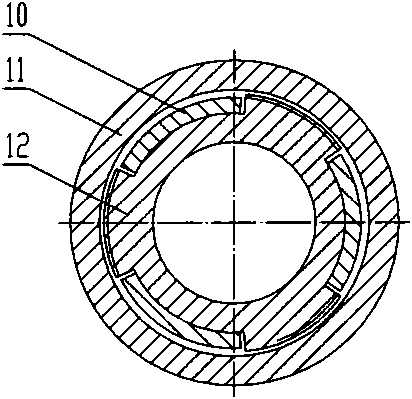

[0009] The embodiment of the present invention consists of an upper joint 1, a piston 2, a hydraulic cylinder 3, a separation joint 4, a push tube 5, a seat seal valve ball 6, a seat seal valve seat 7, a seat seal shear nail 8, a lock ring 9, and a fishing joint 10 , connecting pipe 11, inner pipe 12, unsealing shear nail 13, upper rubber sleeve joint 14, rubber sleeve shaft 15, rubber sleeve 16, lower rubber sleeve joint 17, upper cone 18, slip sleeve 19, slip 20, Closing valve ball 21, upper sealing ring 22, stop joint 24, pin 25, lower sealing ring 26, lower cone 28, upper joint 1 lower external thread is connected with hydraulic cylinder 3 upper part, upper joint 1 lower internal thread and separation joint 4. The upper part is connected. The piston 2 is installed between the hydraulic cylinder 3 and the separation joint 4. Below the piston 2 is a push tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com