Hydraulic setting bridge plug

A bridge plug and hydraulic technology, applied in the field of hydraulic seat sealing bridge plug, can solve the problems of easy falling, not tight setting, etc., and achieve the effects of convenient drilling, reliable sealing, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

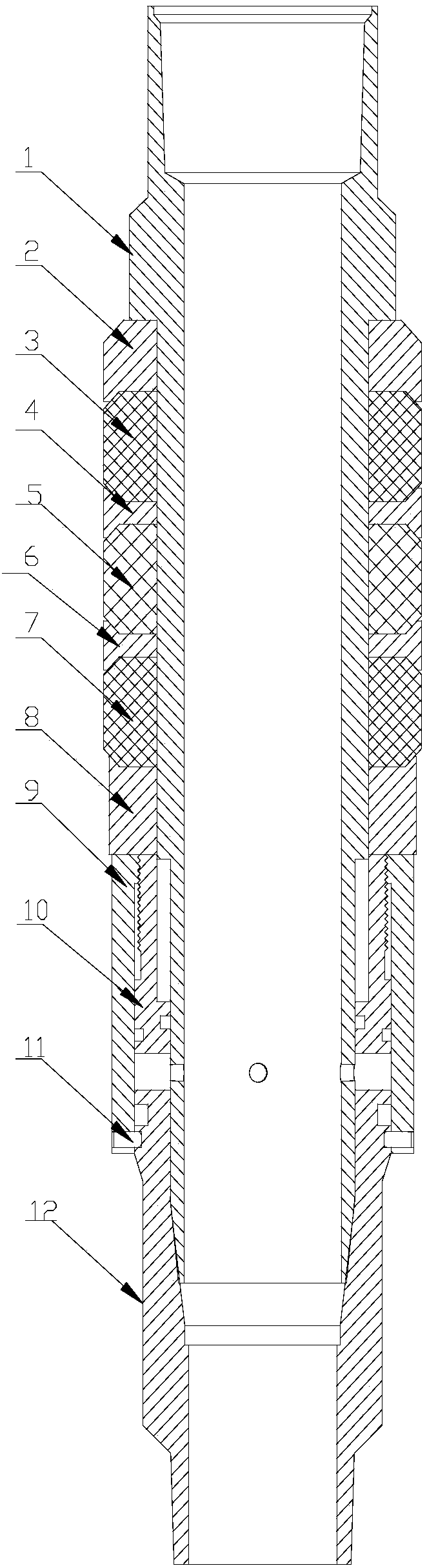

[0008] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 with figure 2 As shown, a hydraulic seat bridge sealing plug includes an upper joint 1, an upper cone 2, an upper rubber barrel 3, an upper spacer ring 4, a middle rubber barrel 5, a lower spacer ring 6, a lower rubber barrel 7, and a lower cone 8 , outer cylinder 9, piston 10, pin 11, lower joint 12; the upper joint is connected with the lower joint, and the upper cone, the upper rubber tube, the upper spacer ring, the middle rubber tube, the lower spacer ring, the lower rubber The cylinder and the lower cone are set on the upper joint from top to bottom in sequence, the lower part of the lower cone is connected to the upper part of the piston, and the piston is placed between the outer cylinder and the upper joint. The lower part of the cylinder is connected with the lower joint throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com