Method for preparing polypeptide by beer sediment

A technology of brewer's grains and wheat grains, which is applied in the field of preparing polypeptides by using brewer's grains, can solve the problems of preparation and activity research that have not been reported, and achieve the effect of obvious hypoglycemic activity and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

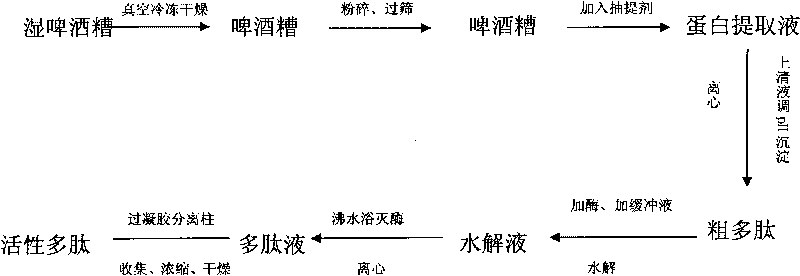

[0029] Embodiment 1 technological process is as figure 1 shown

[0030] (1) Vacuum freeze-dry the wet brewer's grains (provided by Guangzhou Zhujiang Brewery Group Co., Ltd.), pulverize them with a universal pulverizer, pass through a 100-mesh sieve, and obtain brewer's grains; Extracting agent, the extracting agent is 95% ethanol: 0.01mol / LNaOH=1: 2 (v: v), stirred at room temperature for 60min, filtered to remove residue, centrifuged at 2000rpm for 30min to obtain protein extract; The solution was adjusted to pH 4.5 with 0.2mol / L citric acid to carry out protein isoelectric precipitation, the supernatant was removed, and vacuum freeze-dried to obtain crude polypeptide;

[0031] (2) Add disodium hydrogen phosphate-citric acid buffer solution to the crude polypeptide obtained in step (1) to adjust the pH value to 6.5; add Alcalase alkaline protease (purchased from Novozymes), heat to 65 ° C, shake hydrolyzed under conditions for 1 h to obtain a hydrolyzate; the added amount ...

Embodiment 2

[0036] (1) Vacuum freeze-dry the wet brewer's grains (provided by Guangzhou Zhujiang Brewery Group Co., Ltd.), pulverize them with a universal grinder, pass through a 100-mesh sieve, and obtain brewer's grains; Extracting agent, the extracting agent is 70% ethanol: 0.10mol / LNaOH=1: 2 (v: v), stirred at room temperature for 120min, filtered to remove residue, centrifuged at 6000rpm for 10min to obtain protein extract; The solution was adjusted to pH 4.0 with 0.2mol / L citric acid to carry out protein isoelectric precipitation, the supernatant was removed, and vacuum freeze-dried to obtain crude polypeptide;

[0037] (2) Add disodium hydrogen phosphate-citric acid buffer solution to the crude polypeptide obtained in step (1) to adjust the pH value to 8.5; add Alcalase alkaline protease (purchased from Novozymes), heat to 45°C, and shake hydrolyzed under conditions for 2 hours to obtain a hydrolyzate; the added amount of the disodium hydrogen phosphate-citric acid buffer solution ...

Embodiment 3

[0042] (1) Vacuum freeze-dry the wet brewer's grains (provided by Guangzhou Zhujiang Brewery Group Co., Ltd.), superfinely pulverize them, and pass through a 100-mesh sieve to obtain brewer's grains; add 3000 mL of brewer's grains for extraction at a solid-to-liquid ratio of 1:30 per 100 g of brewer's grains. The extractant is 70% ethanol: 0.05mol / LNaOH=1:2 (v:v), stirred at room temperature for 70min, filtered to remove slag, centrifuged at 4000rpm for 20min to obtain protein extract; 0.2mol / L citric acid to adjust the pH to 5.0 for protein isoelectric precipitation, remove the supernatant, and vacuum freeze-dry to obtain the crude polypeptide;

[0043] (2) Add disodium hydrogen phosphate-citric acid buffer solution to the crude polypeptide obtained in step (1) to adjust the pH to 7.5; add Alcalase alkaline protease (purchased from Novozymes), heat to 50°C, and shake hydrolyzed under conditions for 5h to obtain a hydrolyzate; the added amount of the disodium hydrogen phosphat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com