Method for improving activity and stability of immobilized lipase

A technology of immobilized lipase and immobilized enzyme, which is applied in the field of enzyme chemistry, can solve problems such as difficult separation, easy recovery of glycerin, and less alcohol consumption, and achieve simple operation, high promotion and utilization value, and improved catalytic activity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

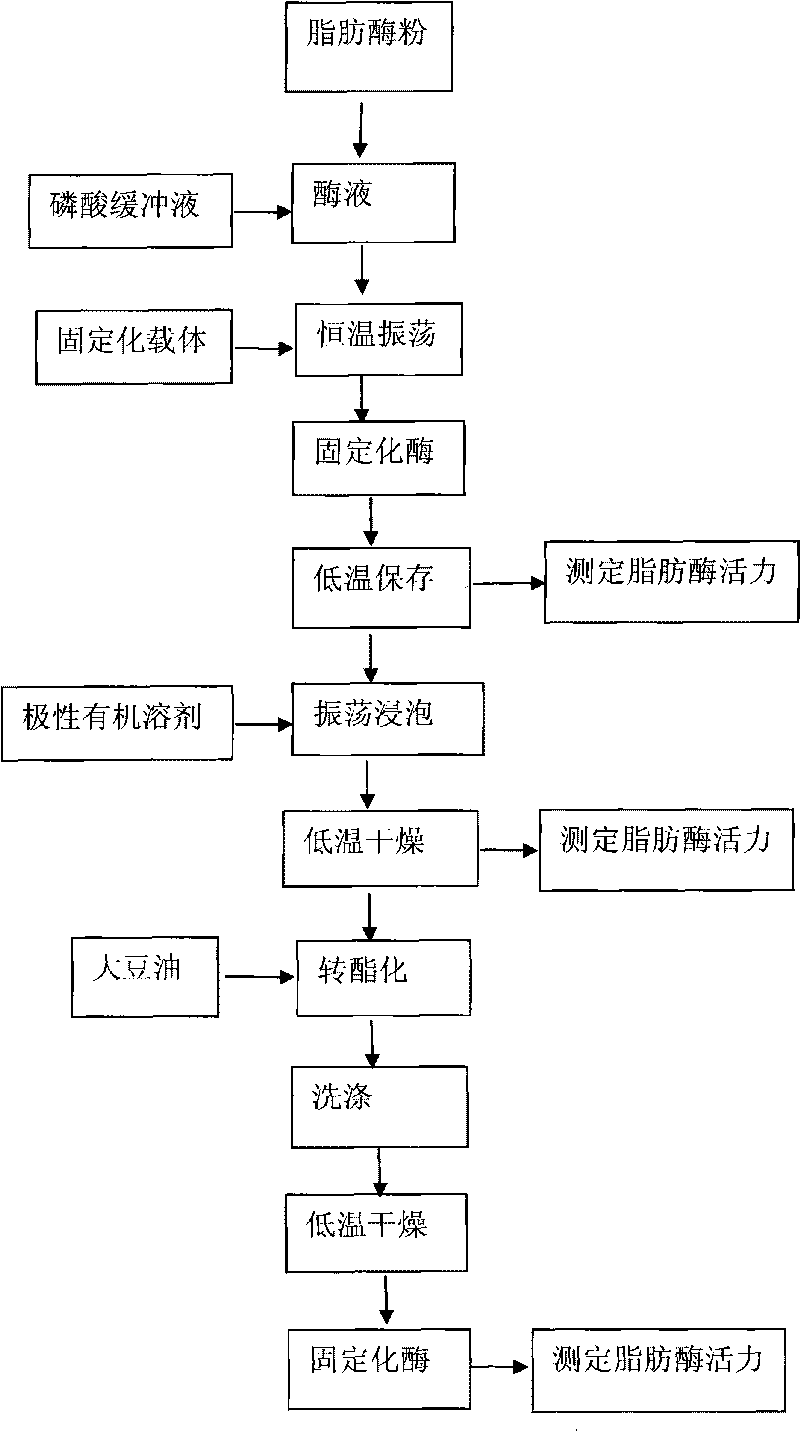

Method used

Image

Examples

Embodiment 1

[0025] a, lipase liquid preparation: get 15g enzyme powder and be dissolved in the phosphate buffer solution (0.05mol / LK) of 300ml, pH7.0 2 HPO 4 -KH 2 PO 4 ), to prepare the lipase liquid of 0.05mg / ml.

[0026] b. Immobilization of lipase: Add 1 g of pretreated 40 mesh activated carbon into 30 ml of enzyme solution, shake and adsorb at 30°C and 150 rpm for 2 hours. The pretreatment is soaking with 1mol / L HCl at room temperature for 3h, and then washing with water until neutral.

[0027] c. Separation and storage of immobilized lipase: the wet immobilized enzyme was separated by filtration and placed at 4°C for 24 hours.

[0028] d. Organic solvent treatment: choose acetone as the immobilized enzyme treatment agent. Add 1 g of wet immobilized enzyme to 30 ml of acetone, shake and treat at 25°C and 150 rpm for 1 hour, filter the treated immobilized enzyme, place it at 4°C for 24 hours, and measure the enzyme activity.

[0029] e. Soybean oil transesterification: Mix 22.5g...

Embodiment 2

[0033] a, lipase liquid preparation: get 15g enzyme powder and be dissolved in the phosphate buffer solution (0.05mol / LK) of 300ml, pH7.0 2 HPO 4 -KH 2 PO 4 ), to prepare the lipase liquid of 0.05mg / ml.

[0034] b. Immobilization of lipase: Add 1 g of pretreated silica gel G into 40 ml of enzyme solution, shake and adsorb at 30° C. and 150 rpm for 2 h. The silica gel G pretreatment method is the same as that in Example 1.

[0035] c. Separation and storage of immobilized lipase: the wet immobilized enzyme was separated by filtration and placed at 4°C for 24 hours.

[0036] d. Use ethyl acetate as the immobilized enzyme treatment agent, add 1g of wet immobilized enzyme to 20ml ethyl acetate, shake at 30°C and 150rpm for 1.5h, filter the treated immobilized enzyme, and place it at 4°C 24h, measure enzyme activity.

[0037]e. Soybean oil transesterification: Mix 22.5g soybean oil, 11ml n-hexane and 1g organic solvent-treated immobilized enzyme, preheat at 30°C for 20min, an...

Embodiment 3

[0041] a, lipase liquid preparation: get 15g enzyme powder and be dissolved in the phosphate buffer solution (0.05mol / LK) of 300ml, pH7.0 2 HPO 4 -KH 2 PO 4 ), to obtain a lipase solution of 0.05 mg / ml.

[0042] b. Immobilization of lipase: Add 1 g of pretreated DM-130 resin into 50 ml of enzyme solution, shake and adsorb at 30° C. and 150 rpm for 2 h. DM-130 resin pretreatment method is the same as embodiment 1.

[0043] c. Separation and storage of immobilized lipase: the wet immobilized enzyme was separated by filtration and placed at 4°C for 24 hours.

[0044] d. Using propanol as the immobilized enzyme treatment agent, add 1g of wet immobilized enzyme to 40ml of propanol, vibrate at 35°C and 150rpm for 1.5h, filter the treated immobilized enzyme, and place it at 4°C for 24h. Determination of enzyme activity.

[0045] e. Soybean oil transesterification: Mix 22.5g soybean oil, 11ml n-hexane and 1g organic solvent-treated immobilized enzyme, preheat at 30°C for 20min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com