Aluminium liquid infiltration-resistant high-aluminum plastic material and preparation method

An anti-aluminum liquid and plastic technology, applied in the field of refractory materials, can solve the problems of plastic and aluminum liquid wetting, etc., to improve the anti-aluminum liquid wetting agent and corrosion, improve wettability, The effect of increasing the wetting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

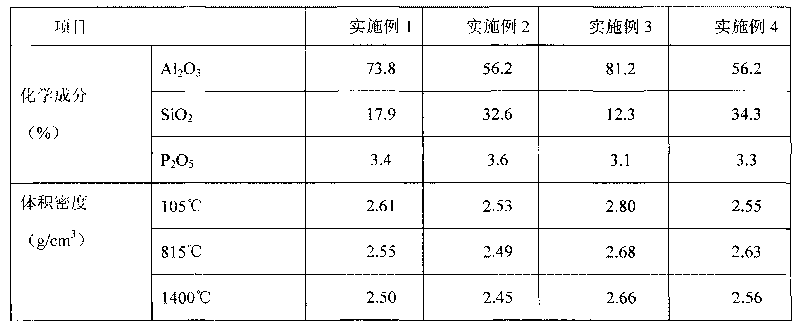

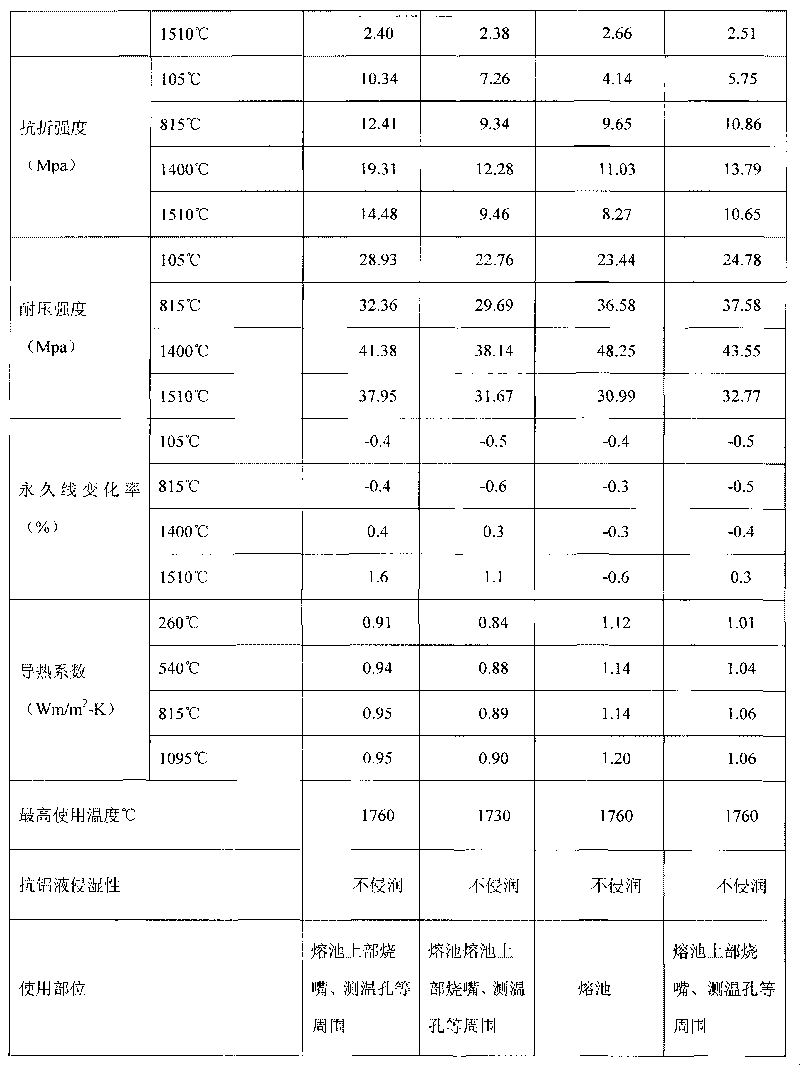

Embodiment 1

[0020] Embodiment 1: fine powder and aggregate all adopt the bauxite of pickling, in described bauxite, Al 2 o 3 The content is 85-90wt%, and the bulk density is 3.15-3.30g / cm 3 ; wherein the percentage of particle size is 5-0.088mm is 55wt%, particle size is less than 0.088mm fine powder part is 30wt%. The additives are mainly 3wt% of silica powder 80-120 mesh, 2wt% of active α-alumina micropowder, 6wt% of sodium bentonite and 3wt% of Jilin ash clay, and 1wt% of anti-aluminum liquid wetting agent (BaSO 4 0.8wt%, Na 3 AlF 6 0.2wt%), the added inhibitor oxalic acid is 1wt%, and the added binding agent is 75% phosphoric acid solution 10wt%. During preparation, the anti-aluminum liquid wetting agent and high-alumina fine powder were co-milled in a vibration mill for 20 minutes according to the ratio described in the examples, so that the anti-aluminum liquid wetting agent and high-alumina fine powder were fully homogenized in advance; the homogenized powder According to the ...

Embodiment 2

[0021] Embodiment 2: preparation process is the same as embodiment 1, and its raw material addition is different, and promptly fine powder and aggregate all adopt the bauxite through pickling, and Al in described bauxite 2 o 3 The content is more than 70wt%; wherein the percentage of the particle size is 5-0.088mm is 50wt%, and the particle size is less than 0.088mm fine powder part is 15wt%. The additives are mainly 5wt% of silica powder 80-120 mesh, 11wt% of active α-alumina micropowder, 9wt% of sodium bentonite and 5wt% of Jilin ash clay, 5wt% of anti-aluminum liquid wetting agent (BaSO 4 4wt%, Na 3 AlF 6is 1wt%), add inhibitor oxalic acid 2wt%, add binding agent is 75% phosphoric acid solution 12wt%, wherein homogenized powder co-grinding time is 25 minutes, trapped material time is 36 hours.

Embodiment 3

[0022] Embodiment 3: The preparation process is the same as that of Example 1, with different amounts of raw materials added. The fine powder and aggregate are all pickled brown corundum, and Al in the brown corundum 2 o 3 The content is not less than 94.5%, and the bulk density is greater than 3.9g / cm 3 Wherein the percentage of particle size 5-0.088mm is 60wt%, particle size is less than 0.088mm fine powder part is 21wt%. The additives are mainly 3wt% of silica powder 80-120 mesh, 2wt% of active α-alumina micropowder, 9wt% of sodium bentonite and 3wt% of Jilin ash clay, and 2wt% of anti-aluminum liquid wetting agent (BaSO4 1.6wt%, Na 3 AlF 6 0.4wt%), add inhibitor oxalic acid 1wt%, add binding agent 75% phosphoric acid solution 8wt%, wherein the co-grinding time of the homogenized powder is 30 minutes, and the trapping time is 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com