Magnetizing water treatment device

A water processor and magnetization unit technology, which is applied in the fields of magnetic field/electric field water/sewage treatment, etc., can solve the problems of unstable treatment effect, low magnetic field center strength, and old age, etc., to achieve stable and reliable treatment effect, reasonable magnetic field design and use. The effect of health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

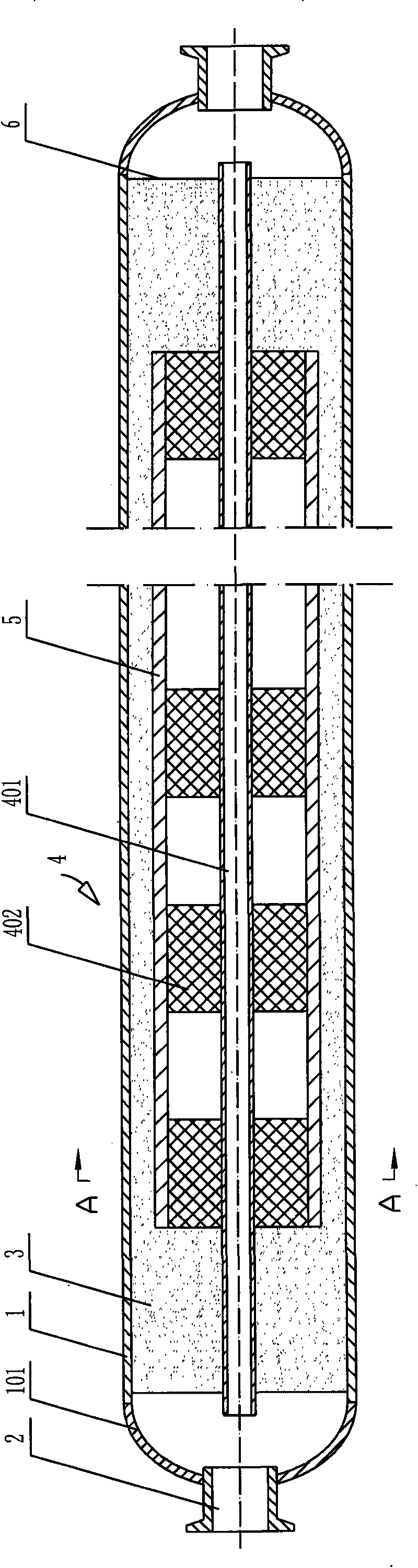

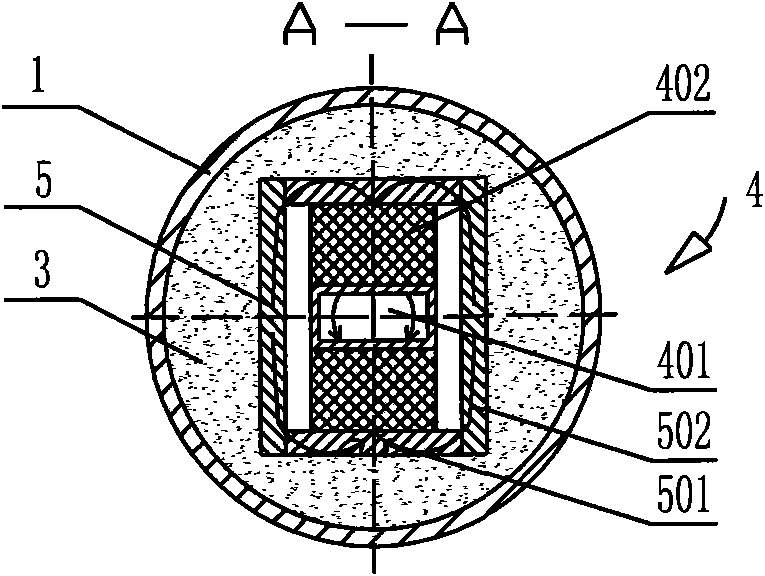

[0019] refer to figure 1 , figure 2 As shown, a magnetized water processor includes an outer tube 1, a joint 2, a filler 3, a magnetization unit 4, a pure iron plate frame 5, a bracket 6, etc.; the outer tube 1 is made of stainless steel, and the two ends are connected with heads 101, the port of the head 101 is connected with the joint 2, the two ends of the outer tube 1 are provided with a support 6, the inner center of the outer tube 1 is provided with a magnetization unit 4, and the two ends of the stainless steel inner tube 401 of the magnetization unit 4 are erected on the support 6 Above; the upper and lower sides of the magnetization unit 4 are provided with a horizontal pure iron plate 501 and the magnetization unit 4 are attracted together to superimpose and upgrade the original magnetic force strength, and the two sides of the magnetization unit 4 are provided with vertical pure iron plates. The plate 502 and the horizontal pure iron plate 501 are attracted togeth...

Embodiment 2

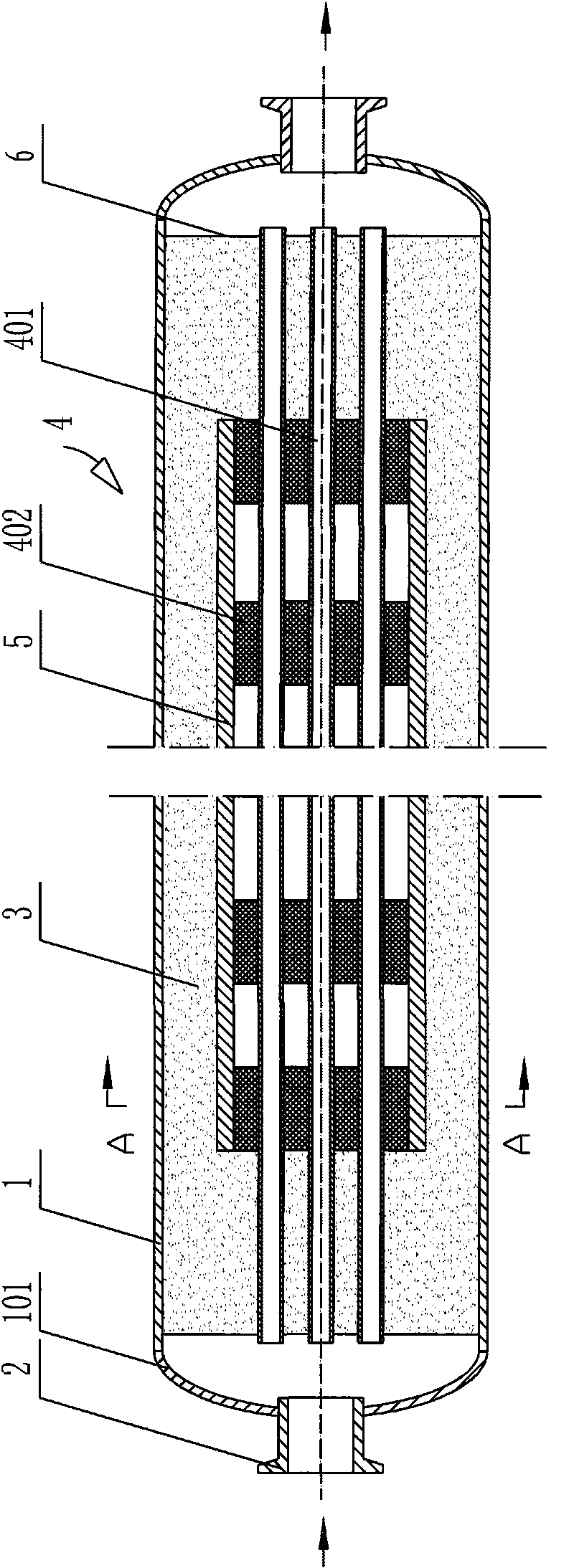

[0022] refer to image 3 , Figure 4 As shown, the stainless steel inner tubes 401 of the magnetization unit 4 are provided in multiples, arranged in multiple rows and double rows. All the other structures are with embodiment 1.

[0023] refer to Figure 5 (a), (b), and (c), in addition to the above arrangement, the arrangement of the stainless steel inner tube 401 of the magnetization unit 4 can also be (a) single row double row, single row N row; (b ) double-row single-row, double-row double-row, double-row N-row; (c) multi-row single-row, multi-row N-row. All the other structures are with embodiment 1.

[0024] The working principle of the present invention: the magnetization unit 4 is used to attract together with the horizontal pure iron plate 501, and the original magnetic strength is superimposed and upgraded to be stronger, and forms a conducting cycle strength with the remaining vertical pure iron plates 502 connected to each other. The magnetic field and the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com