Plasma high temperature carbon conversion gas film reactor

A plasma and membrane reactor technology, which is applied in the field of plasma high temperature carbon conversion gas film reactors, can solve the problems of easy coking of carbon conversion reactors, short service life of the reactors, inability to operate normally, etc., so as to avoid serious coking, The effect of long time and temperature keeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

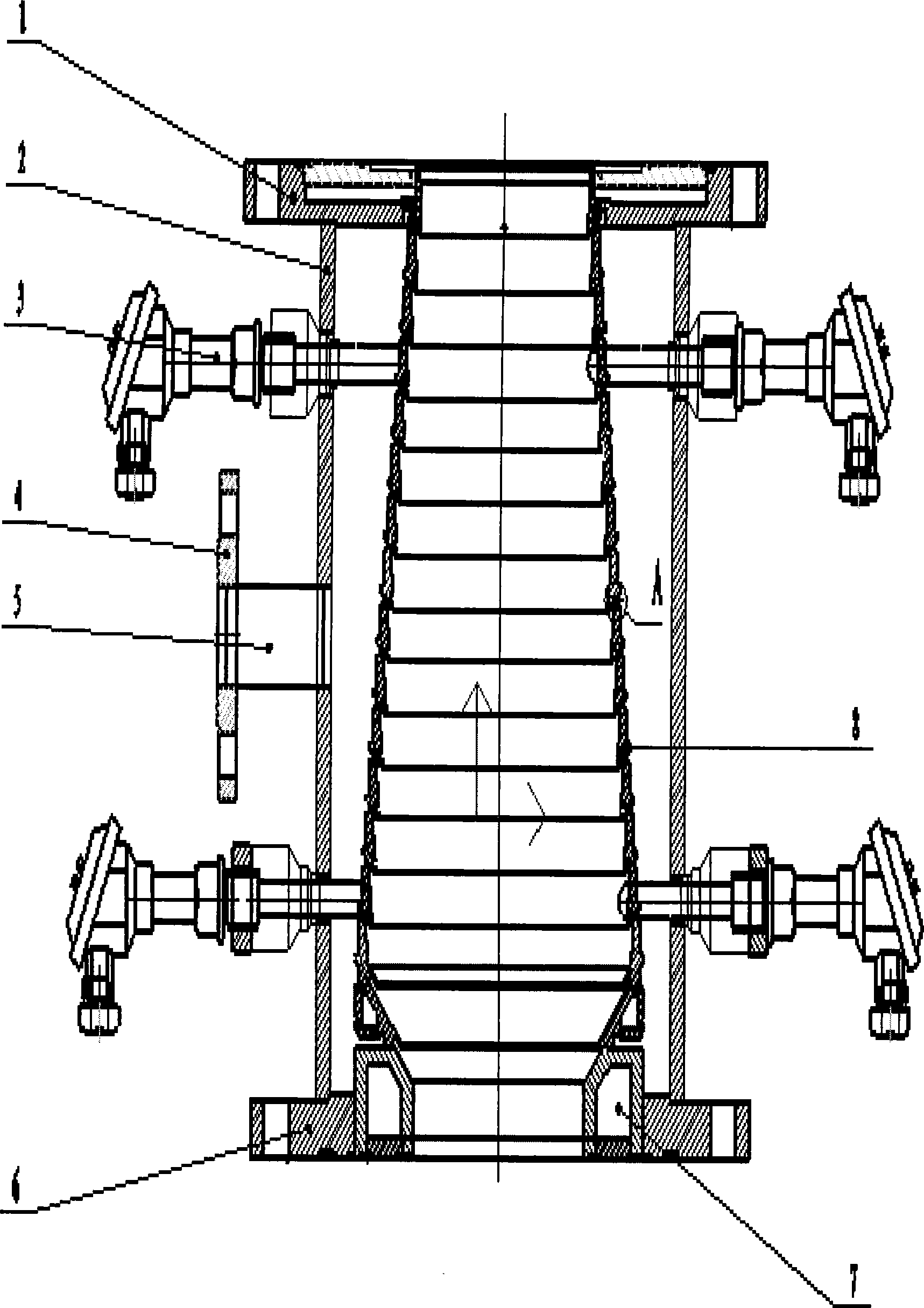

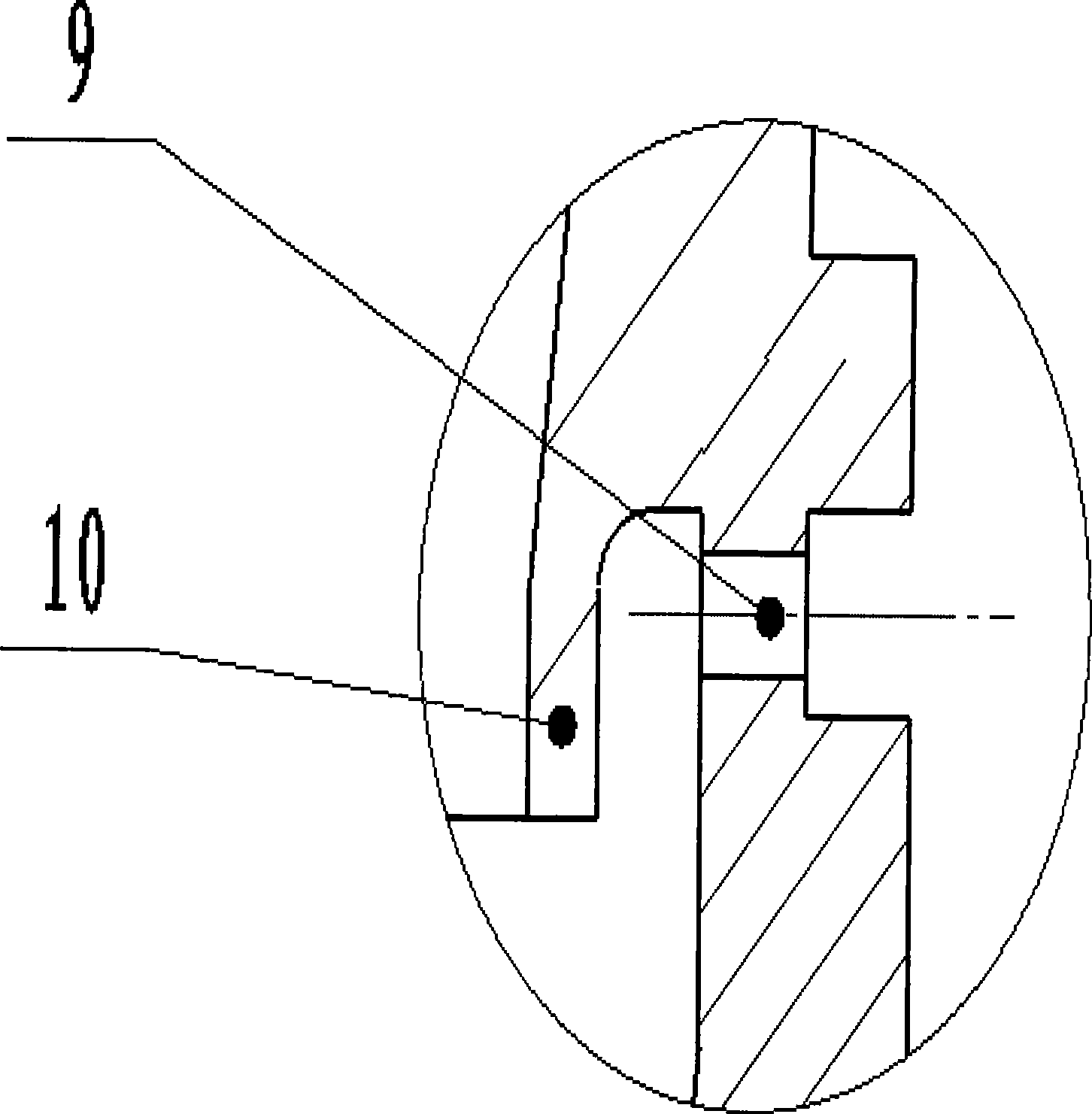

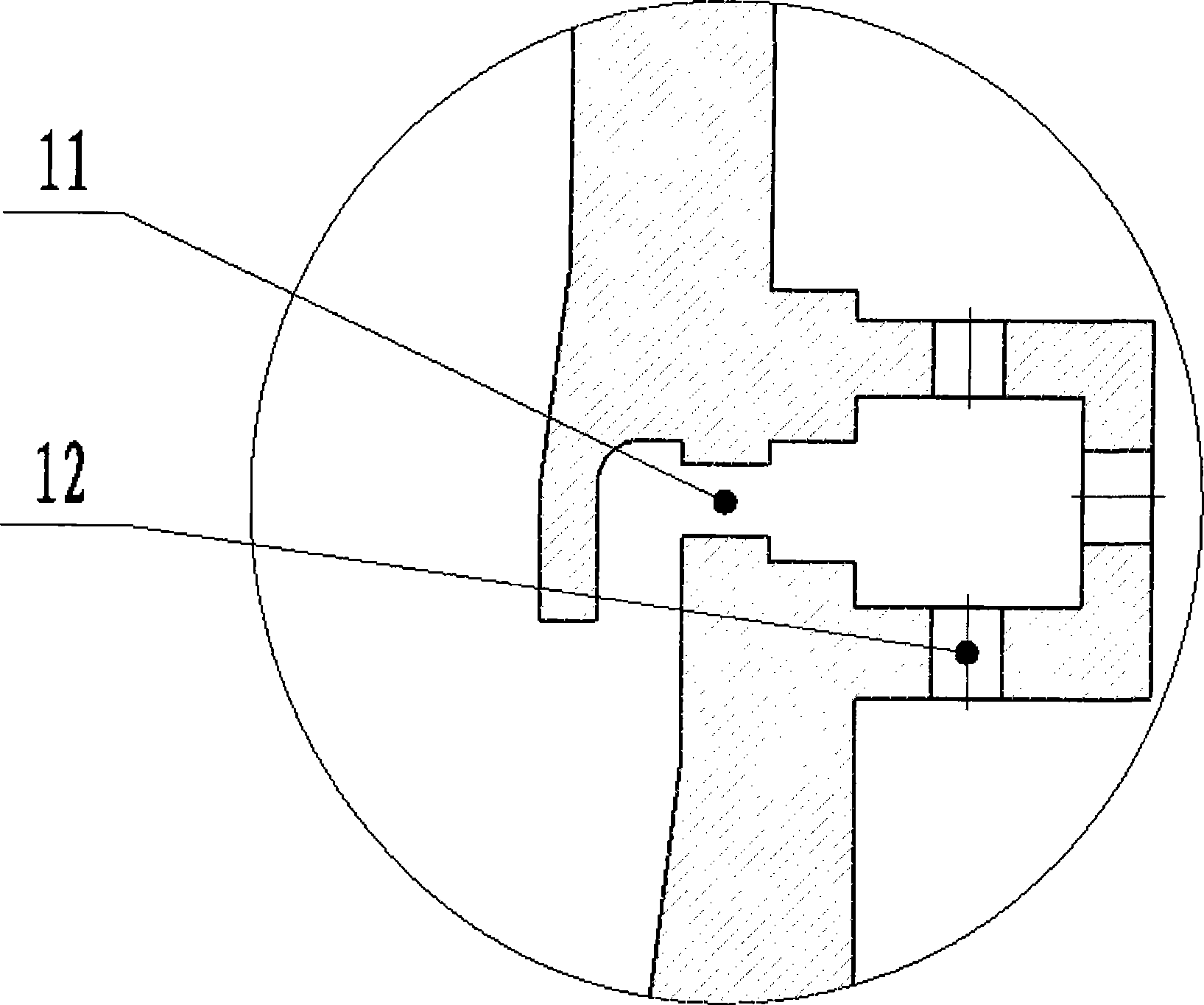

[0014] Refer to attached Figure 1-2 , this embodiment 1 includes parts connected in the following order: upper flange 1, outer cylinder 2, temperature measuring element 3, inlet flange 4, inlet pipe 5, lower flange 6, water-cooled cylinder wall 7, inner cylinder Wall 8, air intake hole 9, baffle plate 10, among which the upper flange 1, outer cylinder 2, inner cylinder wall 8 and lower flange 6 form a cavity, and the rest of the components are connected to the cavity accordingly; the high-temperature airflow passes through the upper method The hole in the middle of the flange 1 enters the inner wall cylinder 8 of the gas film reactor, and the protective gas enters the cavity composed of the upper flange 1, the outer cylinder 2, the inner cylinder wall 8 and the lower flange 6 through the inlet flange 4 and the inlet pipe 5 , through the air inlet 9 provided on the inner wall tube 8, the protective gas enters the high temperature zone and moves in the same direction as the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com