Fusant differential precise injection molding machine

An injection molding machine and melt differentiation technology, applied in the field of precision injection molding machines, can solve the problems of limited service life, long plasticizing time, poor mixing performance, etc., and achieve limited service life, long plasticizing time, mixing The effect of high material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

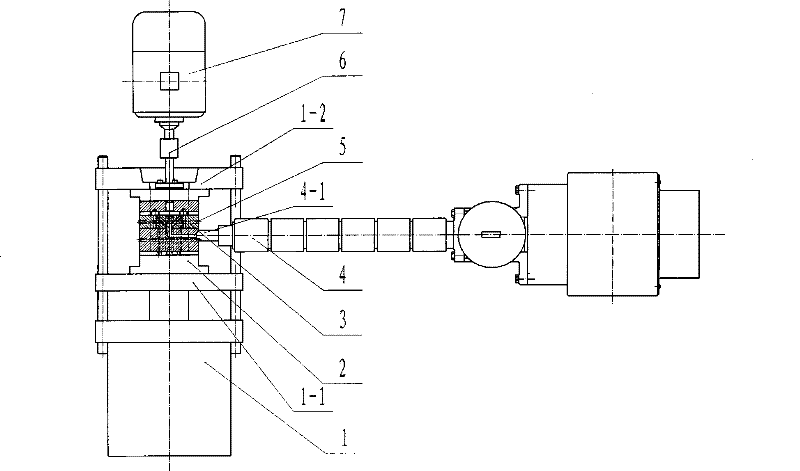

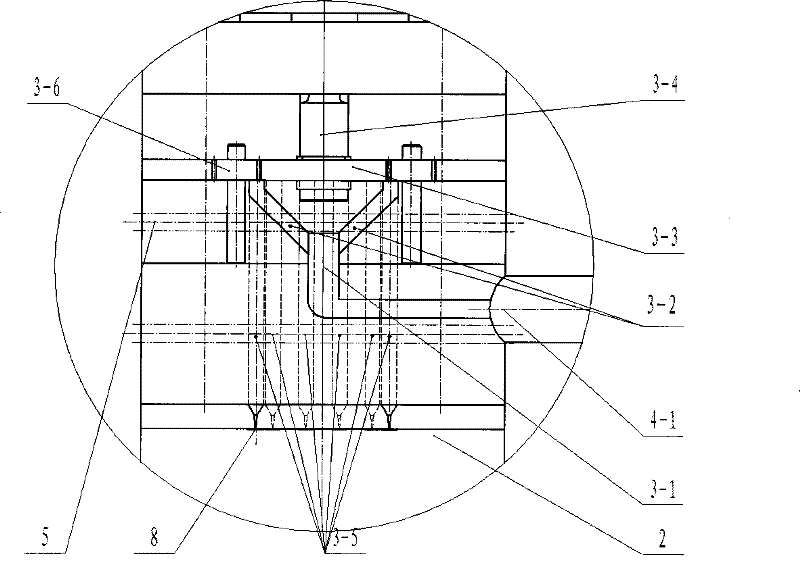

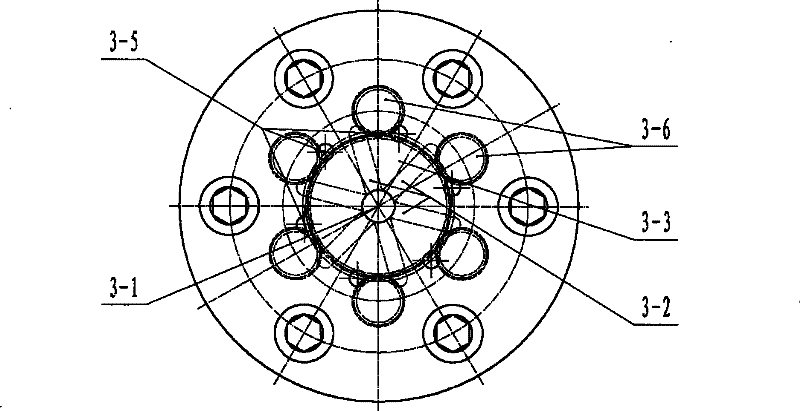

[0021] The melt differential precision injection molding machine of the present invention is such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it consists of an injection molding system (4), a clamping system (1), and a metering and splitting system; the injection molding system (4) and a mold clamping system (1) are the same as those of a conventional injection molding machine. The metering and splitting system is composed of a planetary gear pump (3). ), coupling (6), drive motor (7), controller and heating device (5), planetary gear pump (3) has a main inlet (3-1) and multiple outlets (3-5) , The main inlet (3-1) is connected with multiple inlet branches (3-2), and each branch has a corresponding outlet (3-5) after passing through the gear pump; this embodiment 1 uses a planetary inlet and six outlets Gear pump (3), which has a main inlet (3-1) and six outlets (3-5); this embodiment 2 uses a planetary gear pump (3) with one input and sixteen outputs, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com