Method for quick repair welding, restoring and reproducing of high-alloy cold-working mould

A cold-work die and remanufacturing technology, applied in the field of high-alloy cold-work die steel, can solve problems such as high cost, chipping and wear of cold-work dies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

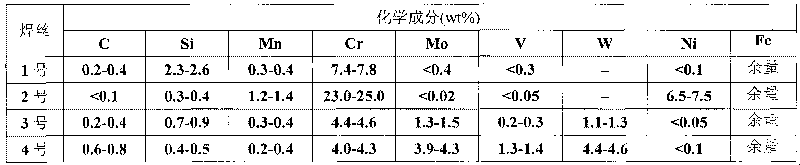

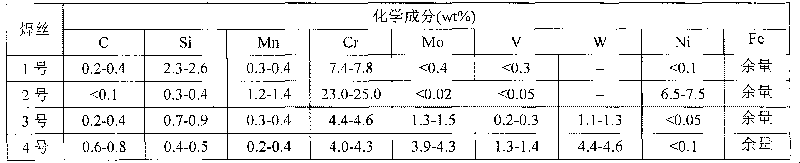

Image

Examples

Embodiment 1

[0021] Example 1: The aging mold repaired in this example is a Cr12MoV edge-trimming and cold-working mold that has been quenched at 1040°C and kept at 210°C for 2 hours and tempered twice. The mold has been repaired many times and used more than 200,000 times , There are two chipped corners and multiple cracks on the cutting edge and the size is deformed. The welding repair and remanufacturing technology of the present invention is used to carry out the following treatment.

[0022] The operation steps of the welding repair and remanufacturing technology adopted in this embodiment are as follows:

[0023] (a) Preheating temperature and holding time before welding repair: First, grind the edge chipping, crack and size collapse of the Cr12MoV mold into a smooth surfacing groove. There are a large number of hidden micro-cracks inside the severely aged Cr12MoV cold-work mold and the micro-cracks on the surface of the mold contain oil stains. Therefore, the preheating temperature...

Embodiment 2

[0029] Example 2: The forming mold repaired in this example is DC53 cold work die steel that has been tempered twice at 200°C for 2 hours after oil quenching at 1030°C. After multiple repairs, it has been used more than 100,000 times. Failures such as cracks, collapse and dimensional deformation. The welding repair and remanufacturing technology of the present invention is used to carry out the following treatment.

[0030] The operation steps of the welding repair and remanufacturing technology adopted in this embodiment are as follows:

[0031] (a) Preheating temperature and holding time before welding repair: Firstly, grind the cracks on the surface of the DC53 mold and the parts with insufficient size to form a smooth surfacing bevel. Choose a moderate preheating temperature of 350°C and keep it warm for 2 hours to protect the mold. Avoid accidental cracking during welding repair, clean the groove to be welded by evaporating oil stains, and improve the quality of the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com