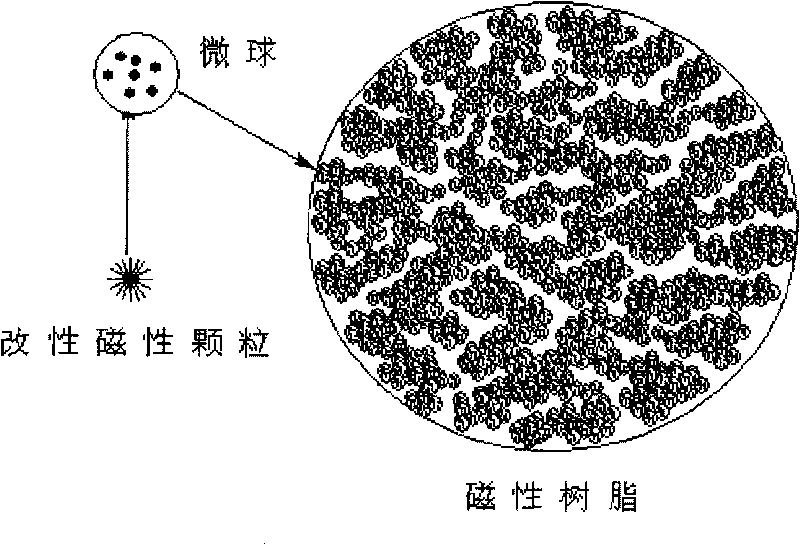

Magnetic cation exchange resin catalyzer and preparation method and application thereof

A cation exchange and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of resin magnetism disappearance, achieve high stability, maintain The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

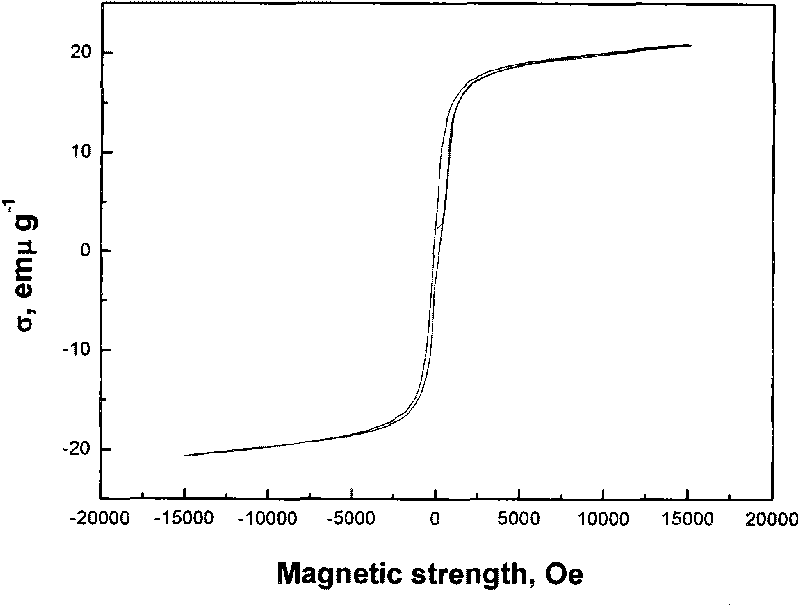

Embodiment 1

[0046] According to the method of titration hydrolysis (according to the method described in the doctoral thesis of Nanjing University of Science and Technology-"Preparation and Application Research of Nano Magnetic Particles and Magnetic Composite Particles"), 4gFe 3 o 4 , still in the reaction solution, keep the pH value at 11, while in a water bath at 50°C, add dropwise 0.7g of 10-undecylenic acid, and stir mechanically for 1.5h; add dropwise 0.4mol / L hydrochloric acid solution to adjust the pH value to 4.5, and the temperature was raised to 70°C, kept for 1.5h, and the reaction was terminated. After the reaction system is cooled, the product is magnetically separated, washed repeatedly with ethanol and distilled water, and dried at 40°C to the surface of 10-undecylenic acid-modified nano-Fe 3 o 4 .

Embodiment 2

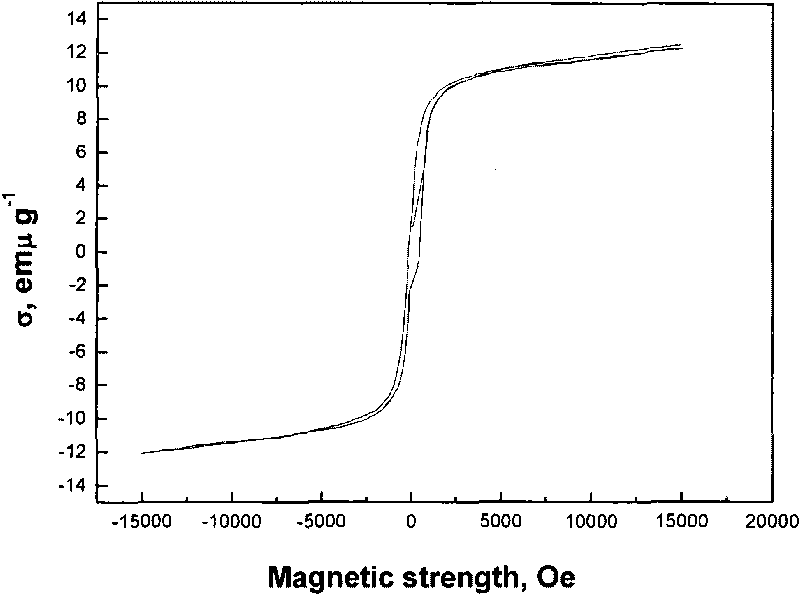

[0048] 4g of Fe with an average particle size of 20nm 3 o 4 , put it into a 2L three-necked flask, add 900mL of distilled water, disperse by ultrasonic wave for 2h, put it in a water bath and raise the temperature to 50°C under mechanical stirring, add dropwise 0.4mol / L NaOH solution to adjust the pH value to 10, and then dropwise add 0.9g Oleic acid, kept for 1h; 0.4mol / L hydrochloric acid solution was added dropwise, the pH value was adjusted to 4, and the temperature was raised to 70°C, kept for 2h, and the reaction was terminated. After the reaction system is cooled, the product is magnetically separated, washed repeatedly with ethanol and distilled water, and dried at 40°C to the surface of oleic acid-modified nano-Fe 3 o 4 .

Embodiment 3

[0050] γ-Fe prepared by thermal decomposition 2 o 3 Nanoparticles (according to the method in Synthesis of HighlyCrystalline and Monodisperse Maghemite Nanocrystallites without aSize-Selection Process, J.Am.Chem.Soc.2001,123,12798), ground into powder, put into 2L three-necked flask, add 1000mL distilled water , ultrasonically disperse for 3 hours, put it in a water bath and heat it up to 50°C under mechanical stirring, add dropwise 0.4mol / L NaOH solution to adjust the pH value to 10, then add dropwise 0.8g dodecanoic acid to the solution, keep for 2h; dropwise add 0.4mol / L hydrochloric acid solution, adjust the pH value to 4.5, and raise the temperature to 70°C, keep it for 1.5h, and the reaction is terminated. After the reaction system is cooled, the product is magnetically separated, washed repeatedly with ethanol and distilled water, and dried at 40°C to the surface of dodecanoic acid-modified nano-γ-Fe 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com