Polyacrylonitrile hydrolyzed modified ultrafiltration membrane resisting protein pollution and preparation method thereof

A polyacrylonitrile-based membrane, polyacrylonitrile technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of membrane fouling, poor hydrophilicity of PAN membrane, etc., and achieve simple preparation process and anti-pollution performance. Enhanced, mildly conditioned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

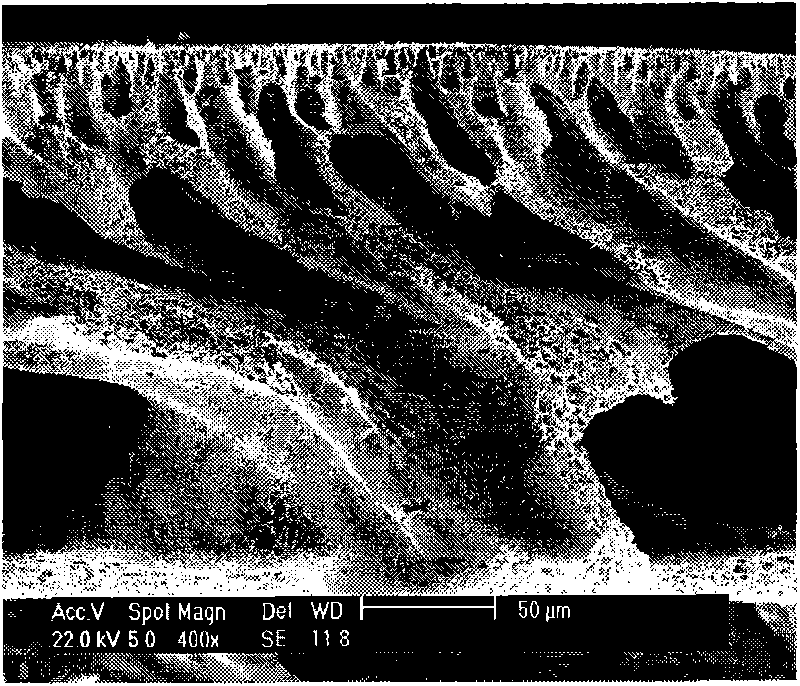

[0019] Weigh 3.2 g of polyacrylonitrile PAN (the molecular weight of polyacrylonitrile is between 80,000 and 200,000, obtained by emulsion polymerization of acrylonitrile monomer). And 16.8g of solvent N, N dimethylformamide DMF was added into a three-necked flask, placed in a water bath at 60°C at a speed of 900r / min and stirred for 5 hours to form a transparent and clear homogeneous casting solution; after stirring evenly, the casting solution Stand at 60°C for 6 hours to remove the air bubbles in the casting solution; take a clean ordinary glass plate and a self-made scraper, place it flat on the table, scrub it with absolute ethanol, take out the casting solution from the constant temperature water bath, and Pour an appropriate amount of casting solution on one end of the glass plate, pull the scraper to the other end of the glass plate at a uniform speed, and scrape out a nascent film about 240 μm thick on the glass plate; place it in the air for 10 to 30 seconds, and then...

Embodiment 2

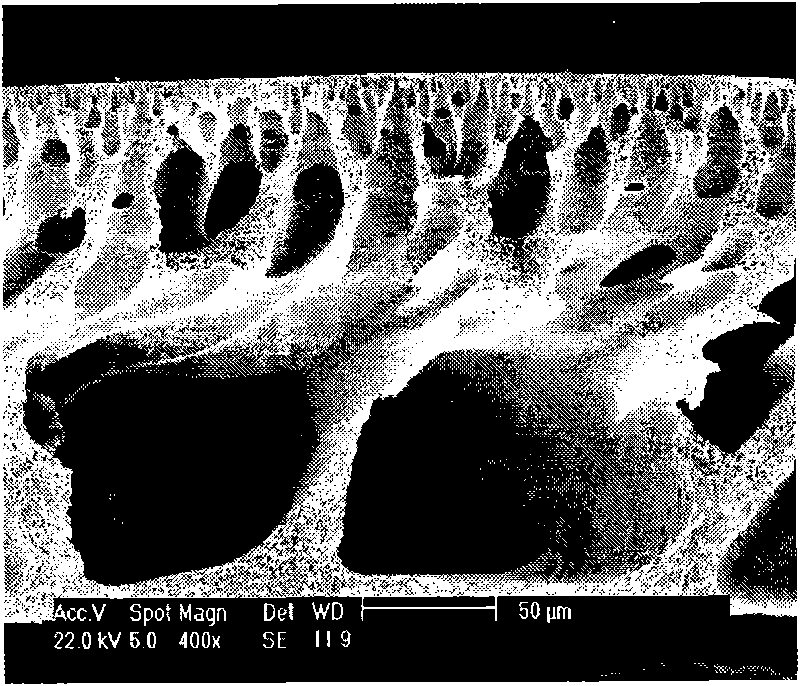

[0021] Weigh 3.2g of polyacrylonitrile PAN and 16.8g of solvent N, N dimethylformamide DMF into a three-necked flask, place in a water bath at 60°C at 900r / min and stir to dissolve for 5 hours to form a transparent and clear homogeneous casting solution ;Stir the casting solution at 60°C for 6 hours after stirring evenly to remove the air bubbles in the casting solution; take a clean ordinary glass plate and a self-made scraper, put it flat on the table, scrub it with absolute ethanol, and remove it from a constant temperature Take out the casting solution from the water bath, pour an appropriate amount of casting solution on one end of the glass plate, pull the scraper to the other end of the glass plate at a uniform speed, and scrape out a nascent film about 240 μm thick on the glass plate; place it in the air for 10-30 seconds After that, put it into a water bath to solidify to form a film, and soak it in deionized water for 24 to 36 hours to obtain the polyacrylonitrile ult...

Embodiment 3

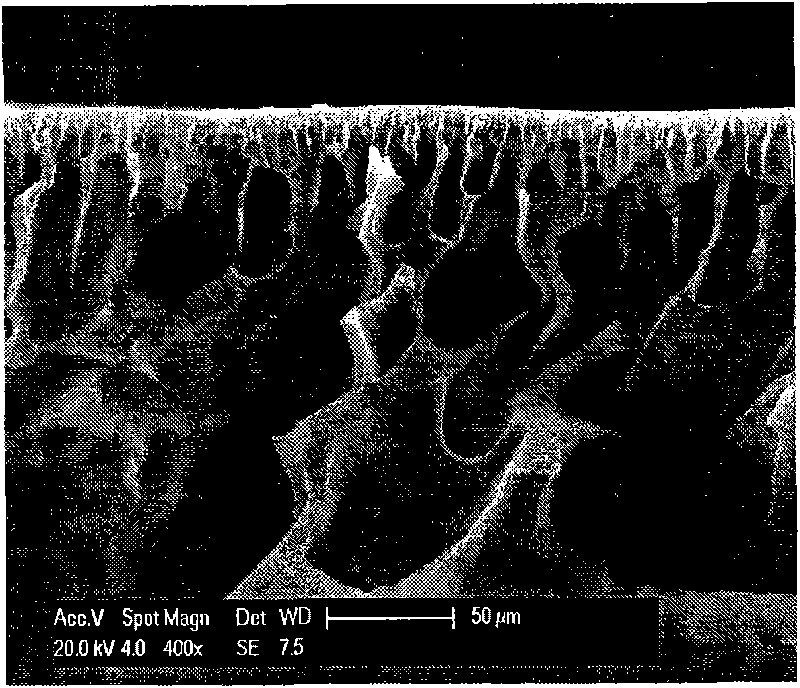

[0023] Weigh 3.2g of polyacrylonitrile PAN and 16.8g of solvent N, N dimethylformamide DMF into a three-necked flask, place in a water bath at 60°C at 900r / min and stir to dissolve for 5 hours to form a transparent and clear homogeneous casting solution ;Stir the casting solution at 60°C for 6 hours after stirring evenly to remove the air bubbles in the casting solution; take a clean ordinary glass plate and a self-made scraper, put it flat on the table, scrub it with absolute ethanol, and remove it from a constant temperature Take out the casting solution from the water bath, pour an appropriate amount of casting solution on one end of the glass plate, pull the scraper to the other end of the glass plate at a uniform speed, and scrape out a nascent film about 240 μm thick on the glass plate; place it in the air for 10-30 seconds After that, put it into a water bath to solidify to form a film, and soak it in deionized water for 24 to 36 hours to obtain the polyacrylonitrile ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com