Process for gathering and purifying panax japonicus total saponins by using D101 macroporous absorption resin

A technology for total saponins of Panax ginseng and adsorption resin, which can be applied in the fields of antitoxin, food science, plant raw materials, etc., and can solve the problems of environmental pollution, high cost, residual organic reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of Bamboo Ginseng Saponin Extract

[0021] Accurately weigh 3.0 g of dried ginseng slices, put them in a round bottom bottle, add 70% ethanol, mix and soak for 12 hours according to the ratio of material to liquid 1:12, heat and reflux for extraction twice, each time for 2 hours; filter the extract, Combined and concentrated under reduced pressure; a concentrated solution with a saponin concentration of 25.9 mg / ml was obtained. as a test solution.

Embodiment 2

[0023] Choice of eluent

[0024] Step 1. Clean the mechanical impurities of the new resin with distilled water, remove the water by suction filtration, then soak in 95% ethanol for 24 hours, and set aside.

[0025] Step 2. After weighing the D101 macroporous adsorption resin, wet-pack the column with 95% ethanol, the column diameter is 15mm, the height is 220mm, and the volume of the column is equilibrated to 33.5ml with distilled water;

[0026] Step 3. Precisely draw 2.24 times the column volume of the concentrated solution with a saponin concentration of 25.9 mg / ml obtained in Example 1, put it on the column, pre-adsorb for 1 hour, re-adsorb the effluent once, collect 2.24 times the column volume of the effluent, and flow rate 2.33 column volume / Hour;

[0027] Step 4, eluting with distilled water until the column effluent has no purple ring reaction;

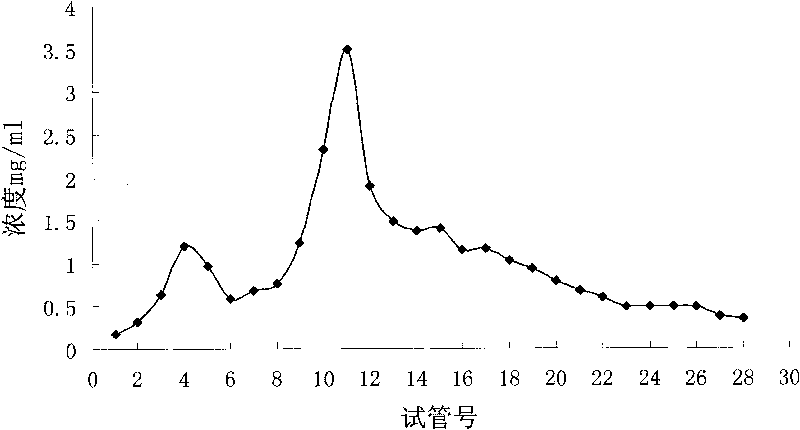

[0028] Step 5, use 30% ethanol, 50% ethanol, 60% ethanol, 75% ethanol, and 95% ethanol for 3 times column volume gradien...

Embodiment 3

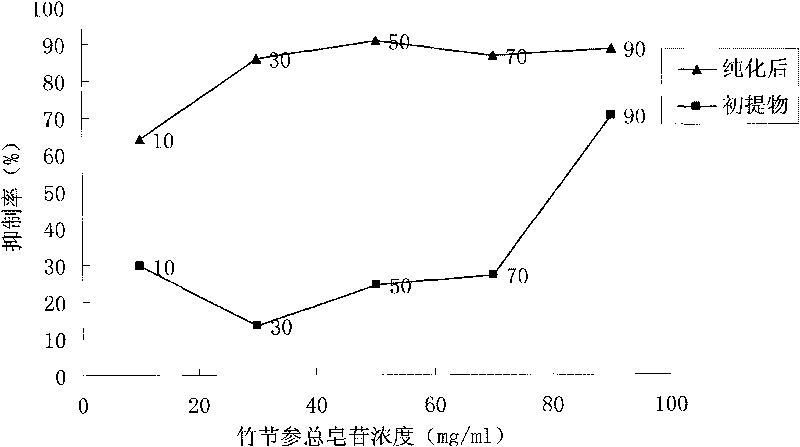

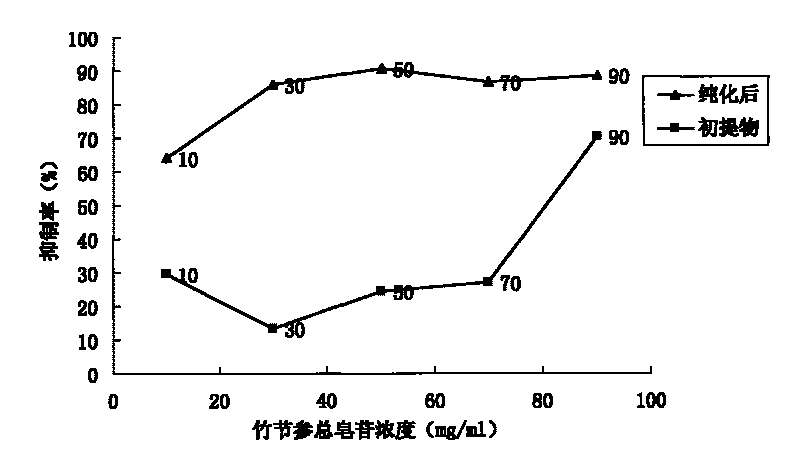

[0032] Enrichment and purification of total saponins from Panax ginseng with D101 macroporous adsorption resin

[0033] Weigh the D101 type macroporous adsorption resin and pretreat it according to the method of Example 2, then use 95% ethanol to wet-pack the column, the column diameter is 15 mm, the height is 400 mm, and the volume of the column is balanced to 33.5 ml with distilled water; the saponin obtained in Example 1 is accurately absorbed The concentrated solution with a concentration of 25.9mg / ml was put on the column with 2.56 times the column volume, and was adsorbed on the column at a flow rate of 1.97 times the column volume / hour, and then re-adsorbed once after static adsorption for 1 hour; first eluted with distilled water, and washed until the column effluent was free of Violet ring reaction; then eluted with 17.08 column volumes of 50% ethanol at a flow rate of 1.81 column volumes / hour, and the eluent was concentrated and evaporated to dryness to obtain the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com