Coaxial constant force spring support hanger

A constant force spring, coaxial technology, applied in the field of supports and hangers, can solve the problems of blocking, locking and unlocking of the locking device of the middle support and hanger, and difficulty in processing and generation, and achieve symmetrical force and simple locking and unlocking , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

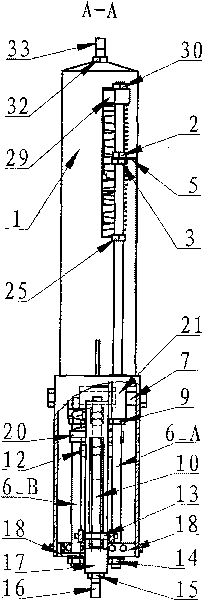

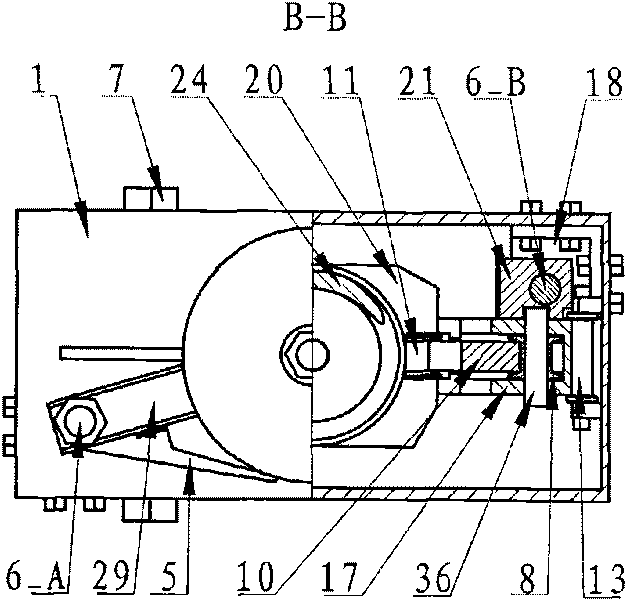

[0046] Such as figure 1 , 2 , 3, 4, and 5, the present embodiment includes housing 1, upper compression nut 2, lower compression nut 3, scale 4, pointer 5, left threaded rod 6_A, right threaded rod 6_B, camshaft 7, outer roller 8. Compression nut 9, cam 10, inner roller 11, roller connecting rod 12, guide wheel 13, lower lock nut 14, compression nut 15, lower boom 16, inner frame 17, locking support plate 18, pull rod 19, Inner spring lower end cap 20, nut 21, outer spring lower end cap 22, spacer ring 23, inner spring 24, upper lock nut 25, outer spring 26, inner spring upper end cap 27, outer spring upper end cap 28, adjustment beam 29, adjustment nut 30, the upper connection nut 31, the compression nut 32, the upper boom 33, the lower connection nut 34, the compression nut 35, the roller shaft 36, the compression nut 37.

[0047] In this embodiment, the shell 1 is welded by the upper cylinder and the lower rectangular box-shaped structure. The boxed structure is welded by...

Embodiment 2

[0053] Such as Figure 6 As shown, the basic composition and working principle of this embodiment are the same as those of Embodiment 1, the main difference is that the supporting method is seat hanging type, that is, the housing 1 is not suspended on the external support structure, but is fixed on the The two supports 39 of the shell 1 are supported on the external support structure 40 , and the inner frame 17 is connected to the pipeline and the equipment 38 through the lower suspension rod 16 and the compression nut 15 .

Embodiment 3

[0055] Such as Figure 7 As shown, the basic composition and working principle of this embodiment are the same as those of Embodiment 1, the difference is that in this embodiment, three support hangers are connected in parallel, the upper part shares a pull-up plate 41 and is connected with the external support structure, and the lower part shares a A drop plate 42 is connected to the piping and equipment 38 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com