High pressure resistant surface mounted fuse

A surface mount and fuse technology, applied in the high-voltage field, can solve problems such as inapplicability, low efficiency, and limited fuse shape design, and achieve the goal of increasing insulation resistance, reducing arcing, and reducing the risk of re-short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

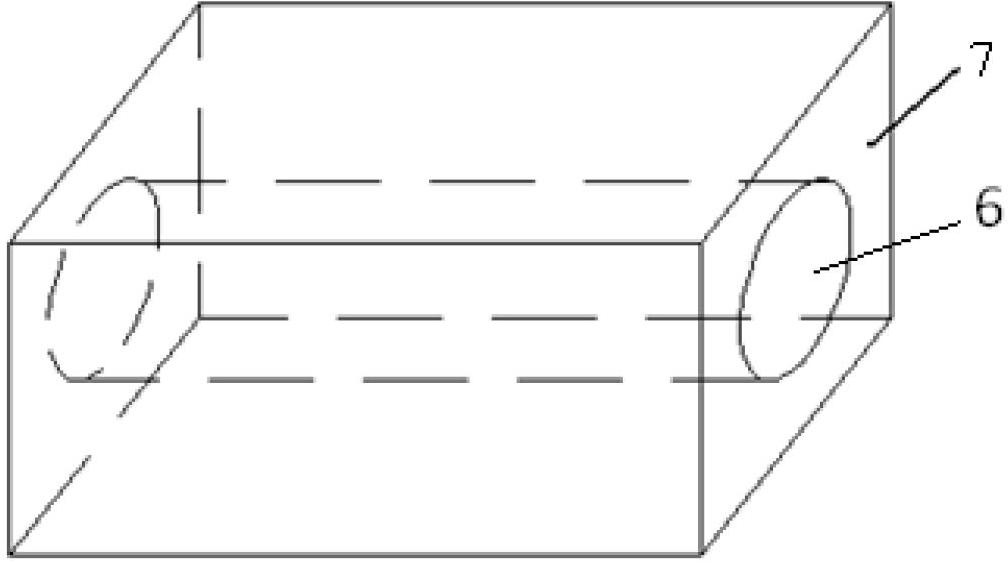

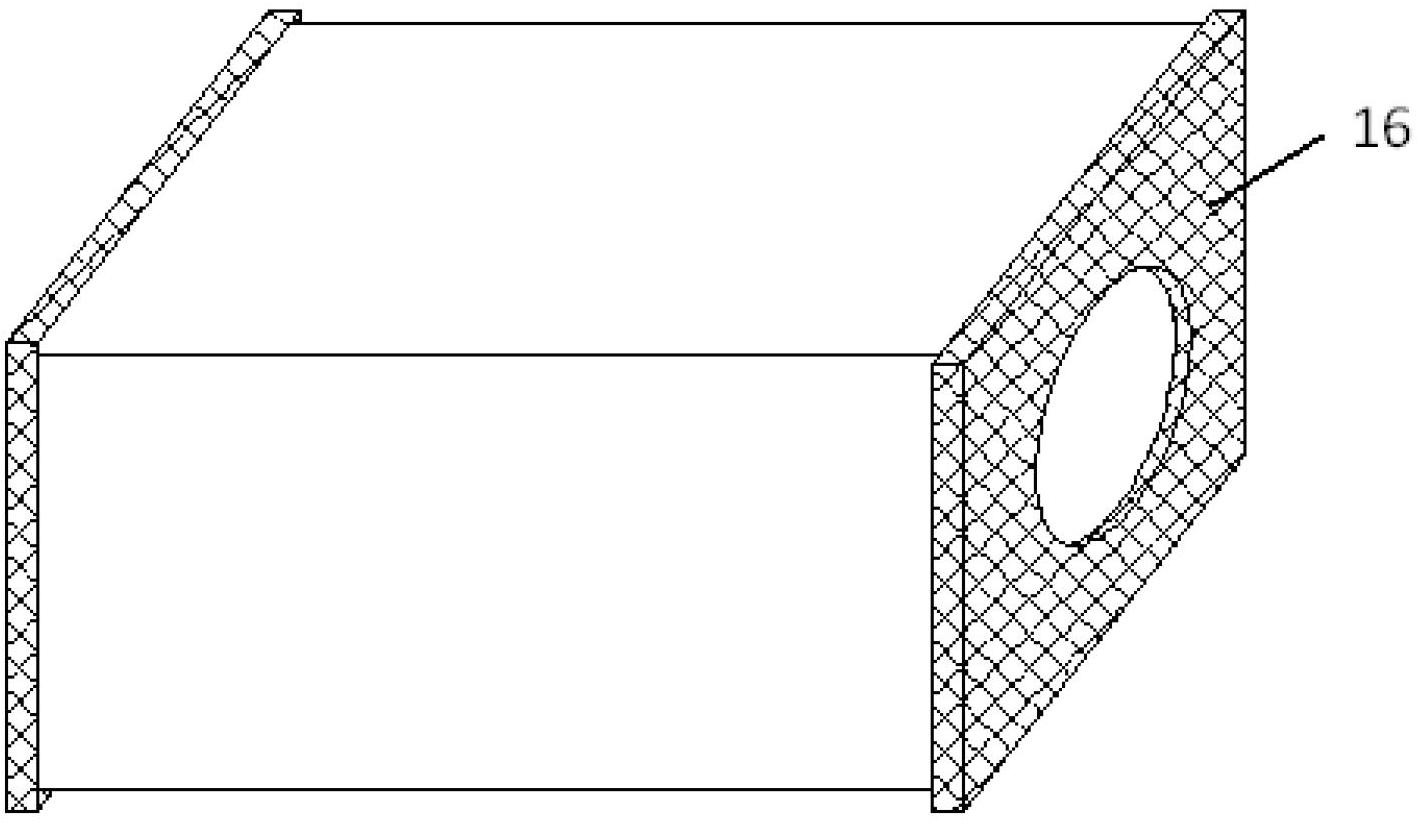

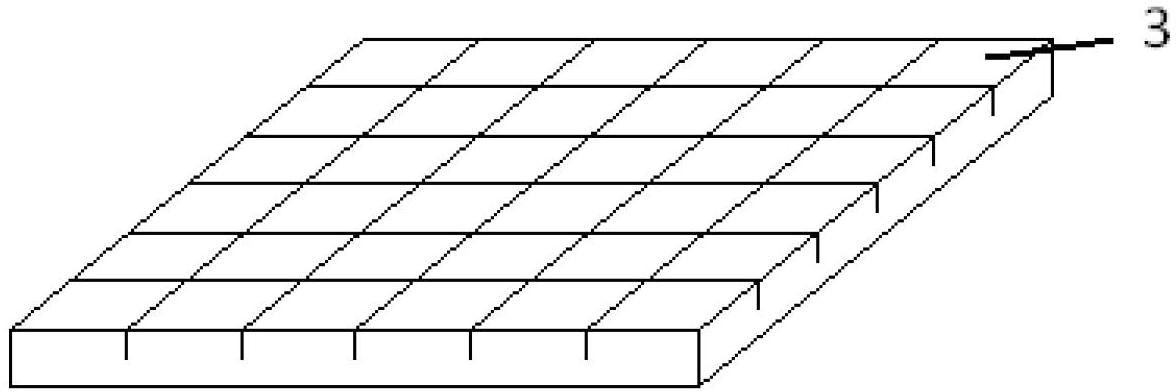

[0031] Embodiment: A high-voltage-resistant surface mount fuse, including a fuse chip 1, the fuse chip 1 is mainly composed of two terminal electrodes 2, a ceramic substrate 3, a first melt layer 4, and a first arc-extinguishing glass layer 5 , a second melt layer 17, a second arc-extinguishing glass layer 18 and a protective layer 15, the first melt layer 4 is located on the upper surface of the ceramic substrate 3, and the two terminal electrodes 2 are respectively located in the first melt The two sides of the layer 4 are electrically connected to the first melt layer 4, and the first arc-extinguishing glass layer 5 covers the first melt layer 4 and the area near the melt layer in the terminal electrode 2; The second melt layer 17 is located on the lower surface of the ceramic substrate 3, and the two back electrodes 13 are respectively located on both sides of the second melt layer 17 and are electrically connected to the second melt layer 17; The arc-extinguishing glass l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com